-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

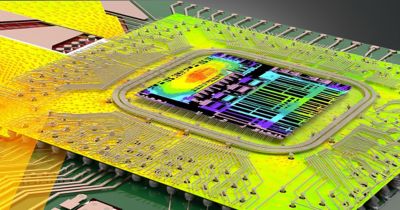

In the engineering world, achieving accurate simulations of dynamic systems is crucial for designing optimized, robust projects. With this in mind, coupling Ansys particle dynamics and multibody dynamics (MBD) solutions brings this type of simulation to the next level.

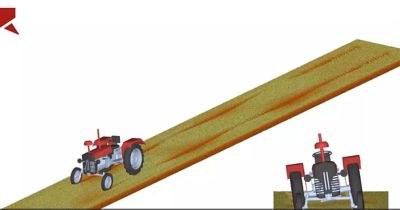

Ansys Rocky particle dynamics simulation software uses the discrete element method (DEM), enabling engineers to model particle shapes, sizes, and interactions; and analyze complex bulk material handling processes, material flow, and particle breakage. Rocky software provides fast, accurate simulations with multiple graphics processing unit (multi-GPU) solver technology.

Ansys Motion MBD simulation software is used to integrate simulation environments for both component and system modeling, providing analysis for both rigid and flexible bodies. It is ideal for analyzing complex systems involving mechanisms, vibrations, and dynamic forces, enabling engineers to optimize designs for durability, safety, and efficiency.

Ansys Motion multibody dynamics (MBD) simulation software

Coupling Rocky software and Motion software offers engineers the unique opportunity to create comprehensive approaches to simulate and analyze complex motions for mechanical systems involving both DEM particle dynamics and smoothed-particle hydrodynamics (SPH) elements and their interaction with these systems.

Discover the Benefits of Coupling Ansys Particle and Multibody Dynamics Software

Rocky software already contains motion frames technology, which enables users to simulate simple movements of equipment and mechanical systems that interact with DEM particles and SPH elements. However, the combination of DEM and MBD opens doors to new simulation possibilities. Coupling Rocky software with Motion software enables more complex analyses, such as geometry-to-geometry interactions, stress and deformation of geometry components, and chained motions emulating real-world environments, in which both particle flow and mechanical movements are considered simultaneously.

Coupling Ansys Rocky particle dynamics simulation software with Motion software enables more complex analyses, such as geometry-to-geometry interactions, stress and deformation of geometry components, and chained motions emulating real-world environments, in which both particle flow and mechanical movements are considered simultaneously.

Key Features of Rocky-Motion Software Integration

- Enhanced accuracy: By simulating particle movement alongside MBD, engineers achieve a more realistic description of how particles interact with moving components, improving predictive accuracy.

- Optimized designs: With this coupling, you can identify crucial points of failure, wear, and stress, enabling you to optimize designs before physical prototypes are built.

- Time and cost efficiency: The integrated workflow reduces the need for repeated testing and physical experimentation, saving both time and development costs.

How Rocky-Motion Software Coupling Works

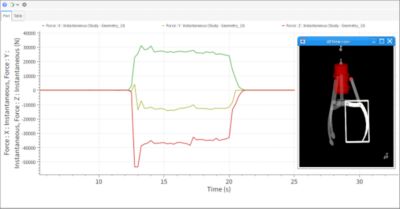

This coupling works by setting up key steps in both software solutions. Once you have the functional mockup unit (FMU) file exported from Motion software that contains all the motion data, Rocky software will import the FMU and apply the imported motion to the simulation while calculating forces and interactions with the bulk material. With this two-way exchange, you can ensure accuracy in your simulation.

You can also postprocess information from imported geometry and plot data, such as force.

Common Industry Applications of Particle and Multibody Dynamics Coupling

Material handling systems: Simulate conveyor belts, chutes, and hoppers to analyze how bulk materials interact with machinery.

Automotive components: Evaluate the wear and tear of vehicle components by simulating particle impingement or friction between moving parts.

Manufacturing processes: Analyze processes involving transport, mixing, or handling of particles alongside mechanical motions, such as in milling or crushing operations.

The coupling of Rocky software with Motion software offers powerful solutions to complex engineering problems.

The coupling of Rocky software with Motion software offers powerful solutions to complex engineering problems. Whether you are optimizing material handling systems, enhancing automotive components, or improving manufacturing processes, this integrated approach ensures better designs and faster time to market. By combining particle dynamics with multibody simulations, engineers can confidently simulate real-world conditions, ultimately delivering more reliable projects.

By combining particle dynamics with multibody simulations, engineers can confidently simulate real-world conditions, ultimately delivering more reliable projects.

For more details on how to set up coupled simulations, visit the Rocky Innovation Space or check Rocky how-to videos, tutorials, and manuals.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.