Case Study

“The principal researcher can create their own data product in a simple way and use the Granta MI platform to curate the data in a validated manner. This gives us a guarantee that we can reuse the data in the future and constitutes a huge competitive advantage.”

— José Antonio Chica-Páez

Digital Transformation Leader at Energy Transition Business Unit, TECNALIA

TECNALIA Transforms Fragmented Project Data into a Strategic Asset with Ansys Granta MI

As Spain’s largest applied research and technological development center, TECNALIA is central to transforming technological research into public benefit. Serving thousands of public and private sector clients, TECNALIA’s work in materials innovation is critical for driving advancements in energy, construction, manufacturing, and mobility. However, decades of project-based work created a significant challenge: fragmented data stored in isolated silos. This approach hindered the ability to reuse knowledge across projects, led to repetitive testing, and made comprehensive data analysis nearly impossible. To overcome these hurdles and unlock the full value of its vast materials data, TECNALIA required a robust, centralized platform to build a new, more strategic data-driven approach.

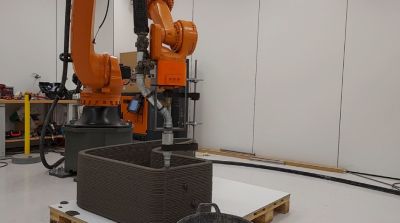

Figure 1. “A construction component manufactured using 3D-printed cement mortar”.

Challenges

- TECNALIA needed to overcome the limitations of its project-based data management, where crucial information was trapped in isolated digital folders, preventing knowledge reuse.

- The lack of a centralized system made traceability and version control difficult, hindering the ability to leverage decades of valuable research data.

- A solution was required to unify heterogeneous data streams, integrate with legacy lab equipment without disruption, and empower researchers to turn raw data into a strategic asset.

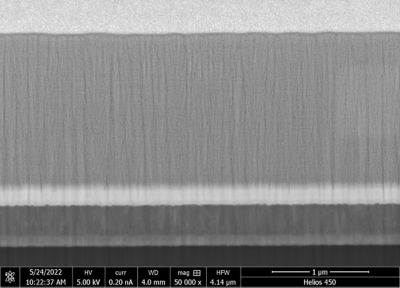

Figure 2. "Advanced surface engineering processes to enhance material resistance, protection, and functionality."

Figure 3. "Cross-sectional SEM view of a PVD, Physical Vapor Deposition, coating designed to enhance wear resistance and corrosion protection."

Engineering Solutions

TECNALIA implemented Ansys Granta MI software to power a centralized knowledge base, shifting from simple data repositories to a more ambitious "data products" concept. The platform enabled researchers to create and curate their own data products using familiar tools, which lowered the barrier to adoption and accelerated a cultural shift.

The ability of the Granta MI platform to manage traceability, access control, IP protection, and quality control were critical features for making the data product concept a reality. The solution's interoperability with other business systems and the capability to extract information programmatically with the Python programming language for advanced analysis were key to its success.

Benefits

- The adoption of the Ansys Granta MI platform has yielded significant benefits in efficiency, data confidence, and strategic value for TECNALIA and its clients.

- Researchers can now capture and analyze data more reliably and rapidly without altering established workflows or upgrading legacy lab equipment, leading to faster adoption.

- The platform provides built-in tools for faster visualization and filtering, connecting data across the organization and increasing confidence in its reuse for future programs.

- Strategically, TECNALIA has transformed its value proposition from delivering simple pass/fail evaluations to providing clients with an evidence-based strategy for improving product performance.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。