Case Study

“Although I had no experience using Ansys before teaching this course, I had been engaged in basic research on the finite element method for many years and had experience using other software. Nevertheless, the fact that I was able to teach over 120 students how to operate the software and they were able to present their analysis results is a testament to its excellent operability.”

- Hiroshi Watanabe, Lecturer, Shibaura Institute of Technology; Director and Chief Technology Officer, Techspire Co. Ltd.

Observing that some structural designs are attractive yet unsafe or impractical, Hiroshi Watanabe, a lecturer at the Shibaura Institute of Technology, saw a need to familiarize designers with mechanics of materials to improve product design. To accomplish this, he introduced his design engineering students to the finite element method (FEM) and mechanics using Ansys multiphysics simulation through the Ansys Academic Program.

Hiroshi Watanabe, Lecturer at Shibaura Institute of Technology and Director and Chief Technology Officer at Techspire Co. Ltd.

Challenges

Design students are not usually interested in the mechanics of materials, possibly due to the mathematics involved, Watanabe says. For this reason, he sought simulation software with effective automatic meshing for complex geometries and an intuitive method for setting boundary conditions to introduce FEM to his students.

In addition, class sessions provide a limited amount of time, and the number of students exceeds 120. Watanabe required user-friendly and intuitive software so students could complete structural analyses and assess mechanical adequacy more easily during lecture periods.

Shibaura Institute of Technology, Tokyo Campus

Engineering Solutions

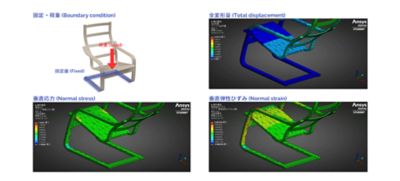

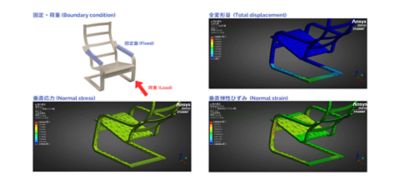

By using the Ansys Workbench platform and Ansys Mechanical software, Watanabe’s students can visualize the magnitude of stress and strain when considering a product’s boundary conditions. This enables students to analyze a product’s fracture margin — an important insight for product design. In connection, students can evaluate which shapes are strong or weak. As a result, Watanabe says his students learned mechanics by discovering that simulation enables them to evaluate the stress and strain of actual products, not just simple geometries.

Another advantage is that by accessing the tools through the Ansys Student software bundle, which is available to download for free, students can continue their studies outside of class.

Simulations from class projects in which Watanabe’s students studied the stress and strain of products through mechanical analyses

By using Ansys simulation, design students were able to analyze a product’s fracture margin, which provides important insight for product design.

Benefits

- Ansys Mechanical software provided automatic meshing for complex geometries and an intuitive method for setting boundary conditions.

- Intuitive solutions and graphical user interfaces (GUIs) helped design students determine the stress and strain of products without having a background in mechanical engineering.

- Structural analyses gave students insight into the fracture margin of a product, which is valuable information for product design.

- Ansys simulation delivered fast results, enabling students to perform comprehensive analyses during class time.

- Access to download Ansys Student software for free empowered students to continue learning outside of class sessions when desired.

Shibaura Institute of Technology, Saitama Campus

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。