Case Study

"The introduction of Ansys optiSLang software has enabled us to consider tackling challenges that we previously wouldn’t have attempted…Now, thanks to optiSLang software, we can push forward aggressively, which has created momentum to actively take on new challenges.”

— Yoshiyuki Kitamura

Group Manager, Structural and Heat Transfer Technology Group, Engine Technology Department, Technology Development Center, Aerospace & Defense Division, IHI

IHI is an industry leader responsible for approximately 60-70% of jet engine production in Japan. To continue driving innovation in aerospace, IHI aims to transform its design process.

Previously, IHI relied on localized design optimization for each design department during the engine design process. However, this local optimization approach has reached its limits and is no longer sufficient to derive viable design solutions.

As a result, IHI decided to explore integrated analysis and design solutions that can be used across multiple domains, aid in automating and streamlining its processes, and ensure traceability.

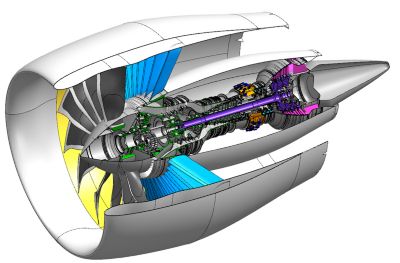

Structure of Turbo Fan Engine

Challenges

Integrating analysis and design solutions, especially across multiple domains, requires a significant time commitment.

- After each department establishes its local automation processes, data handoffs and process integrations are introduced

- Existing design processes and development environments vary from one department to another

- Teams need to standardize the design process to improve quality and reduce errors

- A great deal of experience and intuition is required to select the complex parameters unique to engine design, and part of the process has become dependent on individual expertise

As a result, adopting integrated multidisciplinary domain optimization (MDO) solutions can be a slow process.

IHI’s design process using optiSLang software

Engineering Solutions

To aid in the adoption of an integrated analysis and design solution for its engine design process, IHI used Ansys optiSLang software. IHI leveraged Ansys optiSLang software because of its strong compatibility with Ansys Mechanical™ structural finite element analysis software and Ansys Fluent® fluid simulation software.

In addition, IHI relied on Ansys Japan’s technical assistance and paid engineering services to make its integration of workflows smoother, which in turn lowered the barriers to adopting optiSLang software.

Among various initiatives, the following are highlighted as representative examples of IHI’s use of optiSLang software.

- MDO of aerodynamic and structural analyses for the aerospace engine fan section, leading to a significant reduction in design effort

- Optimization of aircraft engine high-pressure compressor (HPC) blades to effectively reduce vibrations

- Visualization of 1D simulation results for engine system evaluation, enabling a deeper understanding of the overall design

Benefits

The implementation of optiSLang software at IHI resulted in significant improvements in design turnaround time and process efficiency, such as by automating routine and repetitive tasks. This resulted in:

4,000 hours of time saved annually, even during the COVID-19 pandemic, which includes a:

- 30% reduction in design review time

- 70% reduction in design process time

Aiding in design standardization and ensuring the traceability of IHI’s design data were other benefits gained from using optiSLang software.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。