Case Study

The European Space Agency (ESA) is studying an active debris removal mission called e.Deorbit, which is intended to capture an ESA-owned derelict satellite in low orbit and safely crash it into the ocean in a controlled atmospheric reentry. The proposal from a global defense and space manufacturer for this project used model-based systems engineering (MBSE) to simultaneously define the mission requirements and the architecture.

In a parallel internal study, engineers from the company used Ansys ModelCenter™ MBSE software to integrate the simulation tools used to evaluate the performance of the architecture with the system model. This integration demonstrated that it is possible to greatly reduce the time required to verify the requirements and architecture by making it possible to run all the major simulation tools as part of an automated workflow driven by the systems model. This streamlined process increased the number of cases against which the entire system could be simulated by several orders of magnitude. It also makes it possible to cycle through the simulation one time step at a time while simultaneously viewing simulation results for the entire mission. The result is that engineers can have much more confidence in the proposal and managers and customers can receive a much better understanding of the details.

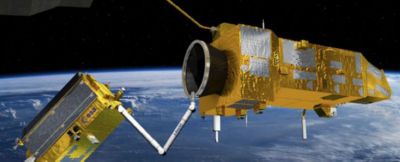

Removing space debris with the e.Deorbit concept

Challenges

On the e.Deorbit proposal, the manufacturer’s engineers addressed these concerns by using system modeling to simultaneously develop the mission requirements and architecture. They developed a SysML model that integrates the safety and architecture requirements, system capabilities, functional architecture, and concept of operations (CONOPS). Developing the architecture and requirements in parallel helped in validating the requirements at an earlier stage in the project, saving considerable time and money.

While this approach was a major step forward, engineers recognized that its benefits were limited by the fact that the domain simulations required to support the development of the architecture were each run manually and separately by engineers responsible for a particular domain. The results from these simulations were later uploaded to a database and used as input parameters for the system model and other simulations. This meant that the performance of the entire system for a particular use case was not clear until each of the simulations involved is completed, which could take days or weeks. Considerable time and effort are required to simulate the performance of the entire system for even a single case, limiting the number of cases that can be run in the architecture definition phase. This creates the potential for errors and unexpected interactions that cost considerable time and money to correct when they are discovered later during the detailed design stage.

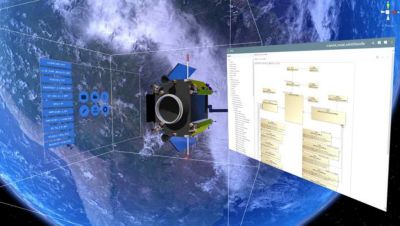

Virtual reality prototype environment to represent the system geometries, dependencies, and complexity

Engineering Solutions

The manufacturer used ModelCenter software to integrate the SysML representation of the e.Deorbit mission with simulation tools that were used to predict the performance of architectural alternatives. Ansys provided custom training and on-site consulting to enable engineers to integrate the system model with the Simulink dynamic model that was used to determine the trajectories of the derelict and mission satellites; the cost model and many domain models used for avionics; and structural and thermal simulation, among others.

ModelCenter software also managed the data flow between the simulation tools so the entire mission or any subsystems could be simulated simultaneously in a single integrated process driven by a common dataset from the system model. Engineers had the choice of cycling through the mission at time intervals of their choice and viewing the results after each step or simulating the entire mission in a batch process and viewing the results after the fact.

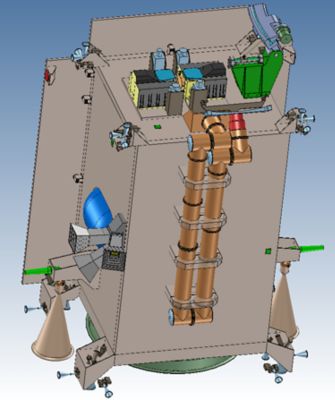

Representation of the geometries of the chaser

Benefits

The integration between system modeling and simulation reduces the time required to simulate the complete mission by orders of magnitude. This makes it possible to examine thousands of cases instead of a few dozen cases that might normally be considered during the proposal stage. For example, the exact tumbling rate of the target satellite at the time of mission execution was unknown. The reduction in time required to simulate the entire system made it possible to simulate the mission for a range of tumbling values to make sure the chosen architecture could support all eventualities.

The ability to simulate the behavior of all subsystems together enables the study of unexpected interactions between the subsystems that cannot be identified in the individual simulations. The detection of these problems in the proposal stage makes it possible to correct them at a cost that can be orders of magnitude lower than would have been required to correct them later in the detailed design phase.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。