Case Study

“With our limited resources, Ansys has been an invaluable tool for us as it allows us to check and simulate everything, even before the components are sent for manufacturing. It has allowed us to cut down on development time and testing numerous physical iterations, which can be prohibitively expensive.”

- Nino Wunderlin, Senior Engineering Staff Member, ASRI

The Aerospace Systems Research Institute (ASRI) aims to aid in developing South Africa’s advanced manufacturing base and to inspire the next generation of aerospace engineers. In pursuit of these goals, the ASRI team is working on multiple award-winning projects, including:

- The Phoenix Hybrid Sounding Rocket Program (HSRP), which seeks to advance propulsion technology, vehicle design, and motor fabrication

- SAFFIRE, a modular and compact 27kN pump-fed liquid propellant rocket engine that uses kerosene and liquid oxygen-driven electro-pumps and is designed to power sovereign orbital-class vehicles

An ASRI rocket test

Challenges

To progress toward its goals and advance its technology, ASRI has to overcome a few main obstacles. One challenge is ensuring first-time-right designs that minimize risk. “You very rarely get a second chance when testing your components,” says Nino Wunderlin, senior engineering staff member at ASRI. Additionally, ASRI needs to develop structurally efficient vehicles to break the space boundary. “Every gram that can be shaved off must be shaved off,” says Wunderlin. Throughout it all, ASRI must minimize its development time while retaining accuracy.

An ASRI rocket launch

Engineering Solutions

ASRI turned to Ansys software to design and develop most of its mission-critical components, such as by using:

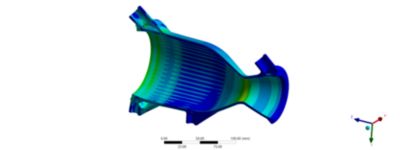

- Mechanical software and the ACP tool to conduct high-fidelity finite element analyses (FEAs)

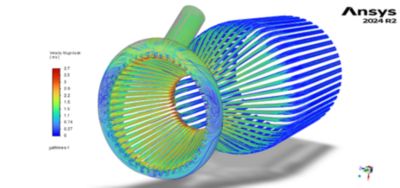

- Fluent software to determine external drag and aerodynamic loading conditions as well as to study internal flow when designing injectors and regenerative cooling passages

- Fluent and mechanical software to perform structural verification

A velocity magnitude simulation analysis

An ASRI hot fire test

Benefits

By using Ansys simulation solutions, the ASRI team can:

- Thoroughly study critical components and analyze structural integrity, vibrational modes, and more. “The Ansys ACP tool coupled with Mechanical software allows us to design the most structurally and thermally efficient components,” says Wunderlin.

- More easily perform thermo-structural and fluid-structural interactions analyses

- Reduce their development time by an estimated 65%

A chamber equivalent stress finite element analysis (FEA)

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。