ANSYS BLOG

April 16, 2021

Driving on Sunshine with Lightyear One

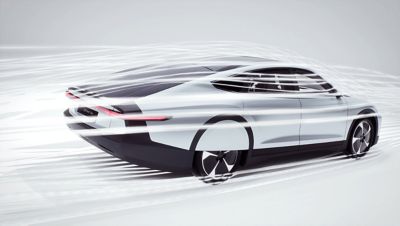

Lightyear engineers are using Ansys Mechanical, Ansys Fluent and Ansys HFSS to design the structure, aerodynamics, and electromagnetic and thermal properties of the five-seat Lightyear One solar car.

Lightyear, an automotive company in Helmond, the Netherlands, is revolutionizing the concept of the eco-friendly automobile by constructing the roof out of solar cells, so you can recharge the batteries as you drive along during the day. It’s almost like taking the charging station with you. The sun does all the work and tops off the batteries.

Lightyear, a member of the Ansys Startup Program has been designing the Lightyear One from scratch — including the lightweight aluminum and carbon fiber chassis, the four in-wheel motors, the powertrain and the solar roof — for maximum range and efficiency.

Lightyear One employs solar cells that stretch from the top of the windshield to back of the trunk.

“Eco-conscious drivers are not worrying about how fast they can go from 0 to 100 kilometers per hour,” says Andrea Carpi, Structural Lead Engineer at Lightyear. “They are looking for efficiency — getting the most range from a clean power source without having to stop frequently to recharge.”

Carpi and his fellow engineers are using Ansys Mechanical, Ansys Fluent and Ansys HFSS to design the structural, aerodynamic, electromagnetic and thermal properties of the five-seat Lightyear One so you can drive up to 725 km (450 miles) on one charge. The solar cells, which stretch from the top of the windshield to back of the trunk, can add up to 12 km of range for every hour you drive in the sunshine. Lightyear One comes with a plug that fits into a regular wall outlet, but, depending on your driving habits and the amount of sunlight in your area, you may not have to use it much.

Lightyear One interior

A Winning Design from the Start

Though now a separate entity from the University of Eindhoven, Lightyear evolved from Solar Team Eindhoven, the student engineering team that won the Bridgestone World Solar Challenge four times in a row between 2013 and 2019 (the competition is held every other year, so they’ve won them all). Competing in the “cruiser” class of “practical solar vehicles,” the team’s Stellar Era solar powered car completed the 3,020 km (1,876 mile) journey through the Australian outback, from Darwin to Adelaide, using only 71.24 kWH of power in October 2019.

Outstanding success like that can get you to thinking about commercializing your solar vehicle, and in 2016 Lex Hoefsloot, a professor of engineering at the university and faculty leader of the team, along with cofounders Koen van Ham, Martijn Lammers, Arjo van der Ham and Qurein Biewenga decided to do just that. The decision was based on the time-honored business formula of “we are going to regret this if we don’t do it,” Hoefsloot, now CEO of Lightyear, told Forbes magazine in November 2020.

Engineering Everything All Over Again

While they learned a lot from the Bridgestone World Solar Challenge, as a commercial company Lightyear had to rethink their design with the consumer in mind, which meant reducing cost and increasing efficiency and comfort. After all, while motivated college engineering students might be convinced to forgo air conditioning during a long road trip in Australia, your average consumer is less likely to put up with the discomfort.

So they used what they had learned to redesign the solar car from scratch. The Ansys Startup Program helped them at this stage by enabling them to test structural, aerodynamic and electronic designs virtually, without incurring the costs of physical prototyping and testing.

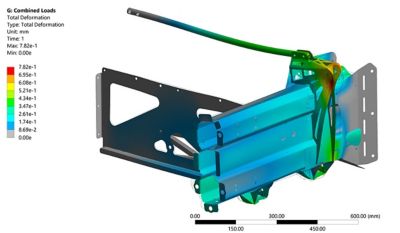

Simulation showing maximum deformation (displacement) of the vehicle front-end when subjected to max road loads.

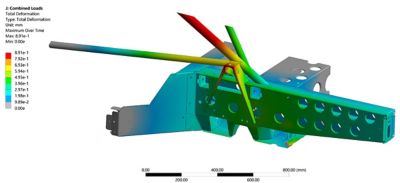

Simulation showing maximum deformation (displacement) of the vehicle rear-end when subjected to max road loads.

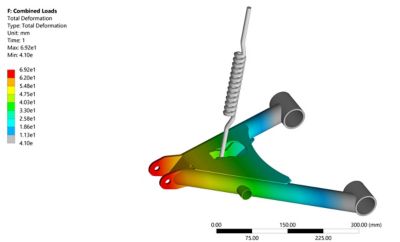

Simulation showing maximum deformation (displacement) of the rear lower control arm (lower part of the suspension assembly) when subjected to max road loads.

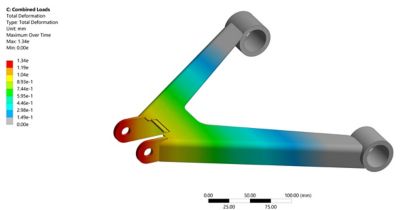

Simulation showing maximum deformation (displacement) of the rear upper control arm (lower part of the suspension assembly) when subjected to max road loads.

“We definitely benefitted from the low-cost simulation capabilities that Ansys offered us through their Startup Program,” says Carpi. “You have to spend your investor’s funds wisely to get the most out of it, and Ansys simulation software helped us to save time and money.”

A unique structural problem in the case of Lightyear One is ensuring that the 5m2 of solar panels can withstand the bumps of the road and even a mild collision without complete destruction. Lightyear engineers used simulation to design a layered structure that includes safety glass on top of the solar cells, as well as support structures underneath, to add strength. They produced a video showing a lightweight engineer walking on the solar roof in soft boots to demonstrate the robustness of the design. Unlike standard solar panels that stop working if a single cell in the structure fails, the Lightyear One system keeps functioning if part of the panel becomes damaged.

Lightyear engineers used Ansys Fluent to help design the shape of the car.

Engineers then performed wind tunnel tests to verify the simulation results.

To reduce drag and lift for aerodynamic efficiency, Lightyear engineers ran simulations using Fluent to help in designing the shape of the car. They then performed wind tunnel tests to verify the results of the simulations. With a flat bottom and a long, tapered top, Lightyear One’s shape resembles an aircraft wing. By making the top longer with a gentle slope, the airflow remains attached to the car, reducing drag compared to a shorter body with a steeper slope. Novel wheel covers also direct the flow of air around the outside instead of into the wheel wells, which could cause more drag.

The Lightyear team also used simulation to design the four independent in-wheel motors that provide power only where and when it is needed. They used Ansys electromagnetic simulations to ensure they are getting the most from their solar panels and battery management system (BMS) simulations to store and distribute power most efficiently.

Lightyear is now accepting reservations for orders for Lightyear One at a price of 150,000 euros for delivery to the EU, Norway and Switzerland, starting at the end of 2021. The rest of the world will have to wait until 2024 and 2025 when a second, more affordable model launches, to get their hands on one of these amazing solar powered automobiles.

Learn more about the Ansys Startup Program.