-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

ANSYS BLOG

August 11, 2022

A New Way to Calibrate Material Models for Simulation

From the aerospace and automotive industries to construction companies and beyond, engineers and product designers throughout the world constantly explore new materials to improve product performance, meet sustainability goals, and reduce cost.

Simulation is often used to analyze the behavior of these materials — commonly alloys, rubbers, or polymers. Based on simulation results and material response, an analyst chooses an appropriate material model to further evaluate materials, verify product performance, and assess efficiency.

Historically, material modeling has never been an easy task. Coefficients, or values, need to be determined for each material in your model to replicate the behavior of the material most accurately. Material properties and characteristics can include thermal expansion, impact resistance, conductivity, density, and more depending on the material and its intended use. Typically, the process involves the aid of a fitting tool, calculations, and a considerable amount of trial-and-error sizing to determine the best set of material coefficients for your material and model.

Today, with Ansys 2022 R2, engineers, designers, and other creators using Ansys Mechanical can now access an easy-to-use application through Ansys Granta MI Enterprise materials data management database to rapidly generate simulation-ready material model coefficients from experimental data.

In its first release, the Ansys Material Calibration app can be used to calibrate rubberlike materials or polymers using a hyperelastic material model or Three Network model. The app significantly reduces manual input, eliminates guesswork, and does not require calculations.

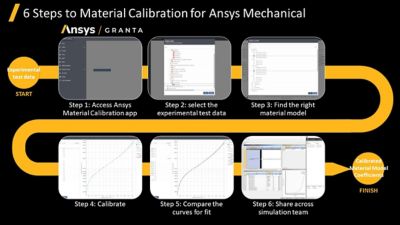

Let’s learn how to access and use the app in six quick steps.

Six Steps to Material Calibration

Step 1: Access Ansys Granta MI Enterprise, open Ansys Material Calibration app

Step 1. Ansys Material Calibration application is found in One MI, the end-user interface for Ansys Granta MI Enterprise.

Granta MI Enterprise is a separately available, web-based solution for managing and sharing material information across an enterprise. You can access Granta MI easily through the Ansys Workbench simulation integration platform and import your experimental test data from Mechanical directly into Granta MI. One MI is the end-user interface for Granta MI, which is where the Ansys Material Calibration app can be found.

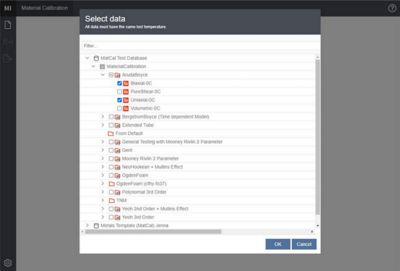

Step 2: Select the test data you want to calibrate

Step 2. Select your test data.

Once you are in the Material Calibration app, select the material records from the test data that you want to calibrate.

Step 3: Select the appropriate material model

Depending on the experimental data you imported (Step 1) and selected to calibrate (Step 2), you will either see a selection of hyperelastic material models or a Three Network model. Only models relevant to the data selected will be visible. If a model is not applicable, it will not appear, which saves you from unnecessary time and contemplation.

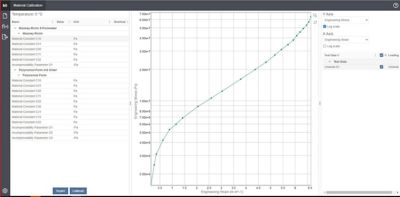

Step 4: Calibrate

After the appropriate model has been selected, it can be calibrated. In this step, the model can be used to generate material coefficients or, if preferred, advanced users can input coefficients manually if the values are known.

Step 4. The selected model and data curve is ready to be calibrated.

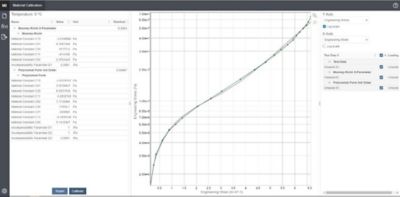

Step 5: Compare the experimental test data for fit

At this point, an Alhazmi-Malaiya Logistic (AML) model curve-fitting algorithm will optimize the calibration and ensure a good fit between your experimental data and simulated results. There is no need for a trial-and-error approach or to re-run simulations. Further, after an appropriate model has been selected you can save the material coefficient values in the Granta MI database for future use.

Step 5. Post-calibration results are shown with available material coefficients.

Step 6: Use generated material model coefficients for accurate simulation

The coefficients you saved in Granta MI during the previous step can be accessed through the engineering data section of Workbench and used in Mechanical to run your simulation. Conducting the calibration process through the app is a fast way to improve simulation accuracy when allocating new material.

Step 6. The calibrated material coefficients are available within the engineering data section of Ansys Workbench.

Materials That Fit Like a Glove

The Material Calibration application can be used across many different industries. In the automotive industry, for example, hyperelastic materials can be used in the simulation of various automotive components.

This simulation illustrates a typical use case using hyperelastic material data to model an automotive rubber boot.

By now you have a basic understanding of what the Material Calibration app can deliver and how to implement it into your workflow. Essentially, the app alleviates the material coefficient fitting process for Mechanical users with:

- Improved accuracy through powerful AML algorithms

- An easy-to-use and intuitive user interface to calibrate experimental material data for material experts and non-experts

- Accessibility through Workbench, making it easier to share results across simulation teams

- Accelerated product performance validation

To see these six steps in action, check out our Ansys Material Calibration app how-to video on the Ansys YouTube channel.