-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

Imagine being part of a team responsible for designing and constructing an off-road vehicle that can withstand rugged terrain, all while managing college coursework and internships. This is the challenge that engineering students face each year in the Baja SAE competition, an off-road student racing competition run by the Society of Automotive Engineers (SAE). For the University of Cincinnati’s Bearcats Baja Racing Club, this challenge was not only about building a vehicle — it was also about restoring the knowledge and processes that were lost for over a decade when the team was not competing.

Ben Roberts, a recent graduate and former member of the Bearcats Baja Racing Club, joined the effort at a critical time. “The University of Cincinnati (UC) requires you to do five co-op rotations or an internship. On my co-op rotations, I learned how to use computer-aided design (CAD), mainly, and I really like doing that kind of work. So, I started on the Baja team as a CAD drafter,” Roberts says.

Roberts, a mechanical engineering student in the class of 2025, stepped into the world of mechanical design, quickly learning the fundamentals of CAD software and finite element analysis (FEA). His journey started with basic CAD drafting for the team and evolved into leading simulation and analysis efforts that would redefine how the team approached building its cars. With much of the team’s previous design files inaccessible and outdated, it essentially had to start from scratch.

Ben Roberts drives the Bearcats Baja Racing Club car in the 2025 Baja SAE competition.

In its pursuit to improve and compete, the team turned to tools from Ansys, part of Synopsys, to enhance its design process. With support from an Ansys Student Team Partnership, the Bearcats Baja Racing Club gained access to professional-grade simulation software and resources that helped the team accelerate its rebuild and refine its designs more efficiently. From analyzing frame strength to ensuring component reliability, simulation became a cornerstone of the work. With simulation as part of their toolbox, the Bearcats weren’t just competing — they were paving the way for a new era of smarter, more efficient design.

Get To Know the Bearcats Team

The Bearcats Baja Racing Club is made up of passionate, driven students who pour their time and energy into designing and building an off-road vehicle for the Baja SAE competition. Composed of about 30 students, the team works collaboratively to bring its vision to life. The team is student-led, and each person plays a specific role on one of four subteams: suspension, frame, drivetrain, and business. A technical director oversees project goals, secures funding, and ensures that resources are allocated effectively.

For senior members, the project often serves as a capstone experience in which academic learning meets hands-on application. Roberts, the team’s computer-aided engineering (CAE) lead, was responsible for much of the design and analysis work, tackling challenges like creating CAD models and performing simulations. Going beyond just creating a functional vehicle, Roberts and his teammates analyzed failures and weaknesses to ensure that each iteration of the car was better than the last. With limited resources and a mix of experience levels, the team leaned heavily on collaboration and creativity to solve problems quickly.

Whether it was long nights finalizing designs or racing against the clock to prepare for the competition, the Bearcats’ dedication showcased their commitment to not only building a competitive car but building each other’s skills along the way.

The Bearcats car on a jump in the 2025 Baja SAE endurance race

Simulation Takes the Front Seat

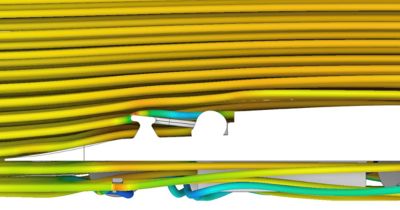

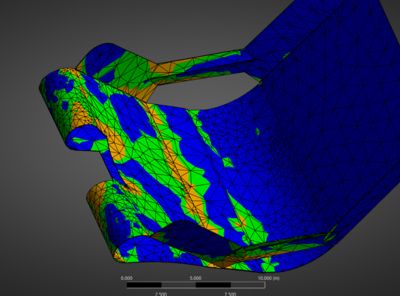

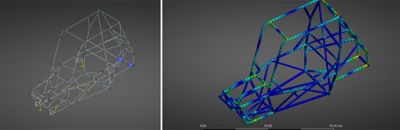

When the Bearcats Baja Racing Club began implementing simulation, everything changed. Using Ansys tools like the Ansys Workbench simulation integration platform, Ansys Mechanical structural finite element analysis software, and Ansys Discovery 3D product simulation software, the team could run tests virtually, cutting down on guesswork and material waste. For Roberts, the process began with creating CAD models of the vehicle’s frame and components, which was a vital step considering that the team didn’t even have a complete model to start with. Ansys software solutions enabled the team to analyze areas of stress, displacement, and potential failure points in ways that it couldn’t before.

Simulation in Ansys Mechanical structural finite element analysis software of the seat of the Bearcats Baja SAE car after a 6-foot fall

“I used the Ansys Workbench platform to run simulations, and it was extremely helpful. This was also coming in with no Ansys experience — very little CAE or simulation experience at all — just from Ansys Innovation Courses and the documentation on the Ansys website,” says Roberts.

Output shaft failure in Mechanical software (left) and simulation of the redesigned output shaft (right)

One standout improvement was in the car’s frame. By running simulations to evaluate its strength and stiffness, the team identified areas where it could safely reduce material without sacrificing performance. The result was a car frame that was 25% lighter and a car that was 120 pounds lighter than its predecessor. Ansys tools also played a role in redesigning other components, like the suspension and brake systems, ensuring they could handle the intense demands of competition.

Simulation of the initial car frame in Mechanical software

The real-time feedback and intuitive workflow of Ansys simulation helped the team quickly identify issues and make adjustments.

“The biggest advantage of having simulation is that you can’t catch everything, but it makes figuring out why something broke a lot faster and helps you design around it much more efficiently. It’s essentially rapid prototyping,” says Roberts.

Roberts and his teammates often worked late nights, swapping out parts and rerunning simulations in Discovery software to stay on schedule. This iterative approach, supported by simulation, became a game changer in achieving efficiency and design accuracy.

“I was able to turn around a simulation in less than a week for a single component or a small assembly,” Roberts says.

Ansys Innovation Courses for the Win

Roberts didn’t let unfamiliarity with Ansys simulation slow him down. He turned to Ansys Innovation Courses — free minicourses that cover a wide array of physics areas and topics, from fluids and structures to electronics and photonics.

“I loved the Ansys Innovation Courses," he says. "They were very direct and allowed me to figure out exactly what I needed every time. I followed the Baja SAE Chassis Analysis and Structural Analysis of a Brake courses almost to the letter, and they gave me a great starting point for further advanced features.”

On the Right Track

Looking ahead, the Bearcats team is focused on ensuring that the knowledge gained through years of hard work isn’t lost again. Building on the lessons learned and the tools used, the team aims to create a streamlined process for future teams. The team has made documentation a key part of its strategy, passing down records of simulations, design iterations, and testing outcomes to new members. The goal is to make it easier for incoming students to pick up where the previous team left off, reducing the time spent reinventing the wheel — so to speak — each season.

Ansys tools remain central to the team’s vision of continued improvement. By leveraging advanced simulations earlier in the design process, the team hopes to further refine components and maximize efficiency without compromising durability. The team is also exploring ways to make simulation more accessible to all members, potentially broadening its use beyond just a few leads. Encouraging every subteam to integrate simulation into its specific tasks could unlock even greater potential in future designs.

With a focus on smarter resource allocation and fostering a culture of collaboration, the Bearcats Baja Racing Club is laying the groundwork for even more competitive seasons ahead. The team’s journey proves that with the right tools and teamwork, the possibilities are endless.

Racing Toward the Future

By integrating Ansys’ tools into its process, the Bearcats team didn’t just build a better car — it built a smarter approach to design.

“By the end of the process, none of the parts I simulated broke during the competition, which was a huge success. The design and analysis efforts paid off, and we were able to perform well, completing 33 laps in the endurance event — our best result so far,” says Roberts.

As it looks to the future, the Bearcats team is proof of what can be accomplished when students combine their creativity with advanced tools and hands-on experience. Their work both exemplifies the spirit of the Baja SAE competition and inspires others striving to push the boundaries of what’s possible in student engineering.

The Bearcats team testing the car before the 2025 Baja SAE competition

Take your team’s designs further with the help of an Ansys Student Team Partnership, and sharpen your engineering skills with hands-on Ansys Innovation Courses.

Just for you. We have some additional resources you may enjoy.

“The biggest advantage of having simulation is that you can’t catch everything, but it makes figuring out why something broke a lot faster and helps you design around it much more efficiently. It’s essentially rapid prototyping.”

— Ben Roberts, former member of the Bearcats Baja Racing Club and mechanical engineering graduate of the class of 2025, University of Cincinnati

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.