-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

Turbomachinery engineers today face growing demands to design complex systems that are more efficient and reliable while also meeting tighter deadlines and higher performance objectives. With industries like aerospace, energy, and automotive pushing for faster development cycles and greater design precision, fragmented design workflows can’t keep up. Engineers today must juggle aerodynamics, thermodynamics, structural integrity, heat transfer, and fluid-structure interactions, often simultaneously.

As pressure to innovate faster grows, the ability to seamlessly integrate conceptual design with detailed, multifidelity simulation is no longer a luxury, but rather a necessity.

Integrating Conceptual Design with Detailed, Multifidelity Simulation

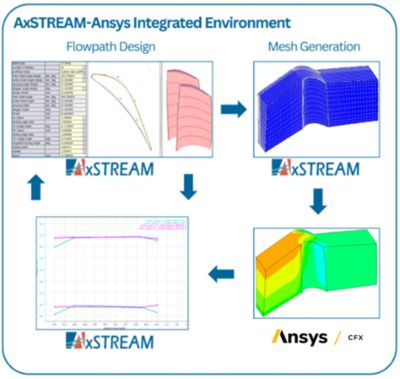

The integration of AxSTREAM and Ansys CFX computational fluid dynamics (CFD) software enables engineers to streamline their workflows, reduce handoffs, preserve design intent, and validate critical performance metrics earlier in the design process. For design teams working on turbomachinery development, this integration helps bridge the gap between rapid iteration and high-fidelity insight to ultimately accelerate innovation across industries.

Integrated workflow used to design, mesh, and complete 3D computational fluid dynamics (CFD) analysis of an axial turbine using AxSTREAM and Ansys CFX software

A Unified Workflow from Design to Simulation Without Compromising Fidelity

AxSTREAM, developed by SoftInWay, Inc., offers a powerful solution for turbomachinery development, guiding engineers from 1D mean line and 2D streamline analysis through to 3D flow path and blade geometry generation. The workflow supports a wide range of configurations — including axial, radial, and mixed-flow machines — all within a single environment.

CFX software is widely used in analyzing fluid flow, heat transfer, and other phenomena, particularly in turbomachinery applications. Known for its accuracy and robustness, CFX software features a fully coupled pressure-based solver that ensures stability across flow regimes, including compressible and incompressible, subsonic to supersonic, and even multiphase flows.

Through AxSTREAM’s direct connection to CFX software, you can automatically transfer geometry and boundary conditions to a validated, industry-standard CFD solver. This integration enables engineers to seamlessly transition from design to simulation while maintaining data consistency and traceability throughout. Using an internally developed plugin, engineers can run performance simulations in CFX software directly from the AxSTREAM interface. Mesh generation is handled with structured or semi-structured elements optimized for turbomachinery, which lets engineers assess performance, loss mechanisms, and flow behavior quickly and accurately.

Once simulation is complete, the results can be post-processed using AxSTREAM, enabling users to visualize velocity vectors, pressure and temperature distributions, and key performance parameters. CFD results from CFX software can also be added to the AxSTREAM project tree, making it easier to generate plots and compare simulation outputs with the design data. Cross-comparison helps support design decisions by providing a more detailed look into flow behavior and performance trends.

Integrating 3D CFD simulations into the design process not only gives engineers greater insight into flow behavior, but it can also help pinpoint potential performance losses and thermal risks early on. This accelerates development timelines and reduces costs while optimizing results.

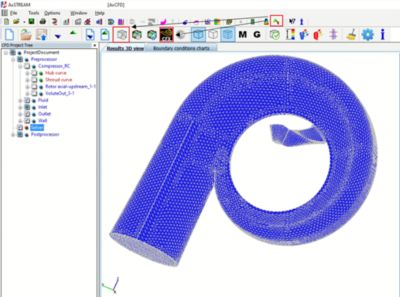

AxSTREAM AxCFD window with the CFX simulation integration platform

Real-World Example: Three-Stage Axial Turbine

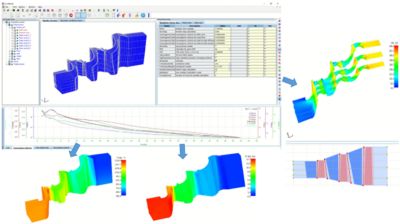

To see this workflow in action, let’s take a look at the process of designing and analyzing a three-stage axial turbine. The process begins in AxSTREAM, in which engineers can define stage parameters and generate the flow path geometry. Blade profiles are then created and refined based on aerodynamic criteria.

Next, the geometry is passed to AxSTREAM’s CFD tool, which automatically generates structured or semi-structured meshes for each blade passage. These meshes capture important details like tip gaps and hub-shroud contours while following the flow direction to ensure that the simulation remains stable. From there, the full 3D model is launched in CFX software directly from AxSTREAM to perform the simulation.

The simulation results show turbine performance under real-world conditions, revealing pressure losses, flow separation zones, and key thermodynamic and kinematic parameters. The integration of AxSTREAM and CFX software enables engineers to iterate quickly and achieve the strongest design results within a workflow.

Integrated workflow used to mesh, simulate, and post-process a three-stage axial turbine using AxSTREAM AxCFD and CFX software

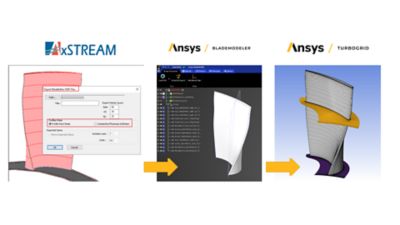

Exporting Geometry to Ansys in Neutral Data Format

Beyond the initial design and simulation step, the interplay between AxSTREAM and CFX software also speeds up the process toward more detailed modeling and manufacturing. You can export blade geometries in neutral data format (NDF), which can be directly imported into Ansys TurboGrid turbine blade meshing software and geometry editing tools, such as BladeBuilder and BladeEditor. This enables engineers to efficiently create complex blade solids, like buttons and squealer tips, parameterized geometry edits, and high-quality structured meshes in TurboGrid software for final CFD runs.

The ability to carry a design from mean line to CFD to manufacturability with a unified workflow saves a significant amount of time that would otherwise be lost to file conversions, manual rework, and geometry misinterpretations. This makes it easier for global and multidisciplinary teams to collaborate and innovate effectively.

Neutral data format (NDF) export of an axial turbine rotor from AxSTREAM to the BladeBuilder solver in Ansys TurboGrid software

Empowering Faster, Smarter Design Decisions

These two software platforms provide more than just a streamlined workflow. It’s a smarter way to design. Engineers can move from early design decisions to detailed 3D CFD validation, all without leaving a unified environment. With the CFX software and AxSTREAM, engineers eliminate manual data transfers, reduce the risk of errors, and accelerate innovation.

By integrating simulation early on, performance issues can be caught before they become costly setbacks. In today’s fast-paced, performance-driven world, AxSTREAM, connected with Ansys, is an advantage that sets innovators apart and keeps them at the forefront of design evolution.

Learn more about how Ansys CFX software and SoftInWay can help with your turbomachinery needs.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.