-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

ANSYS BLOG

July 31, 2023

What is an Integrated Circuit (IC)?

In our modern world, just about everything is woven together by electronics. From microwaves to satellites, electronics-powered devices are infused into our every waking moment. Today, even our sleep includes digital acoustics, haptics, and analytics. But while the systems that light, connect, and move our lives can vary greatly, nearly every electronic device has one or more of the same fundamental building block — the very small and very complex integrated circuit.

What is an Integrated Circuit?

An integrated circuit (IC) — commonly called a chip — is made out of a semiconductor material called silicon, in which small electronic components called transistors are formed within the silicon and then wired together with interconnects layered on top of the silicon surface.

Integrated circuit diagram

What Do ICs Do?

You’re probably familiar with the little black boxes nestled neatly inside your favorite devices. With their diminutive size and unassuming characteristics, it can be hard to believe these vessels are actually the linchpin of most modern electronics. But without integrated chips, most technologies would not be possible, and we — as a technology-dependent society — would be helpless.

Integrated circuits are compact electronic chips made up of interconnected components that include resistors, transistors, and capacitors. Built on a single piece of semiconductor material, such as silicon, integrated circuits can contain collections of hundreds to billions of components — all working together to make our world go ‘round.

The uses of integrated circuits are vast: children’s toys, cars, computers, mobile phones, spaceships, subway trains, airplanes, video games, toothbrushes, and more. Basically, if it has a power switch, it likely owes its electronic life to an integrated circuit. An integrated circuit can function within each device as a microprocessor, amplifier, or memory.

Integrated circuits are created using photolithography, a process that uses ultraviolet light to print the components onto a single substrate all at once — similar to the way you can make many prints of a photograph from a single negative. The efficiency of printing all the IC’s components together means ICs can be produced more cheaply and reliably than using discrete components. Other benefits of ICs include:

- Extremely small size, so devices can be compact

- High reliability

- High-speed performance

- Low power requirement

Evolution of IC Manufacturing

ICs have been making increasingly sophisticated devices possible for nearly 75 years. But how did they begin? The idea of putting several components on one chip was first considered in the 1950s, with different scientists being credited with independently developing similar designs at approximately the same time.

Since their creation, integrated circuits have gone through several evolutions to make our devices ever smaller, faster, and cheaper. While the first generation of ICs consisted of only a few components on a single chip, each generation since has prompted exponential leaps in power and economy.

- 1950s: Integrated circuits were introduced with only a few transistors and diodes on one chip.

- 1960s: The introduction of bipolar junction transistors and small- and medium-scale integration made it possible for thousands of transistors to be connected on a single chip.

- 1970s: Large-scale integration and very large-scale integration (VLSI) allowed for chips with tens of thousands, then millions of components, enabling the development of the personal computer and advanced computing systems.

- 2000s: In the early 2000s, ultra-large-scale integration (ULSI) allowed billions of components to be integrated on one substrate.

- Next: The 2.5D and 3D integrated circuit (3D-IC) technologies currently under development will create unparalleled flexibility, propelling another great leap in electronics advancement.

The first IC manufacturers were vertically integrated companies that did all the design and manufacturing steps themselves. This is still the case for some companies like Intel, Samsung, and memory chip manufacturers. But since the 1980s, the “fabless” business model has become the norm in the semiconductor industry.

A fabless IC company does not manufacture the chips they design. Instead, they contract this out to dedicated manufacturing companies that operate fabrication facilities (fabs) shared by many design companies. Industry leaders like Apple, AMD, and NVIDIA are examples of fabless IC design houses. Leading IC manufacturers today include TSMC, Samsung, and GlobalFoundries.

Types of Integrated Circuits

ICs can be classified into different types based on their complexity and purpose. Some common types of ICs include:

- Digital ICs: These are used in devices such as computers and microprocessors. Digital ICs can be used for memory, storing data, or logic. They are economical and easy to design for low-frequency applications.

- Analog ICs: Analog ICs are designed to process continuous signals in which the signal magnitude varies from zero to full supply voltage. These ICs are used to process analog signals such as sound or light. In comparison to digital ICs, they are made of fewer transistors but are more difficult to design. Analog ICs can be used in a wide range of applications, including amplifiers, filters, oscillators, voltage regulators, and power management circuits. They are commonly found in electronic devices such as audio equipment, radio frequency (RF) transceivers, communications, sensors, and medical instruments.

- Mixed-signal ICs: Combining both digital and analog circuits, mixed-signal ICs are used in areas where both types of processing are required, such as screen, sensor, and communications applications in mobile phones, cars, and portable electronics.

- Memory ICs: These ICs are used store data both temporarily or permanently. Examples of memory ICs include random access memory (RAM) and read-only memory (ROM). Memory ICs are among the largest ICs in terms of transistor count and require extremely high-capacity and fast simulation tools.

- Application-Specific Integrated Circuit (ASIC): ASICs are designed to perform a particular task efficiently. It is not a general-purpose IC that can be implemented in most applications but is instead a system-on-chip (SoC) customized to execute a targeted function.

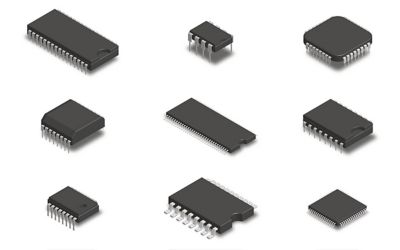

Types of IC Packaging

After designing and manufacturing a chip, there is a third and final step in which the chip is tested and packaged. This is one more highly specialized subfield in the semiconductor industry.

Because the actual silicon chip is too small and delicate to manipulate directly, IC packaging provides something more substantial to work with. A protective casing — typically an enclosure made of plastics or ceramics with integrated leads or bumps — enables us to connect the tiny chip to a circuit board. Depending on the intended application, IC packaging can vary in size and shape.

Some common IC packages include:

- Dual in-line package (DIP)

- System-on-chip (SOIC/SOC)

- Pin grid array (PGA)

- Quad flat package (QFP)

- Ball grid array (BGA)

- Integrated Fan Out (InFO)

- 2.5D-IC and 3D-IC

What are 2.5D and 3D-ICs?

As consumption of everything digital continues to put pressure on devices to be faster, smarter, and smaller, the need for ICs to process more information more efficiently is never-ending. In the most recent generation, there are two very promising new options: the 2.5D and 3D-IC.

In 2.5D-ICs, two or more chips are placed next to each other, on the same surface plane, in a technique called interposer technology. This side-by-side proximity across a shared base increases the interconnect density.

Now take that logic a level up, literally, and you have 3D-ICs. This logic-on-logic sandwich is created by stacking chips or wafers on top of each other. In addition to increasing the interconnection even more, 3D-ICs offer more processing power in a smaller footprint and are highly flexible for using different technology nodes.

A major new challenge posed by these multi-die packaging technologies is heat dissipation. When you consider that a high-performance computing (HPC) chip can easily consume over 200 watts, it becomes obvious that overheating and thermal management are major limiting factors when you start stacking several of these chips closely together.

By making ICs more efficient in how they connect, 2.5D and 3D technologies are overcoming the scaling challenge that engineers have been tackling since the 1950s: “How do we get more with less?”

Improving IC Design

By enabling engineers to predict the performance of ICs, accurate signoff verification is critical to optimizing the design process for nearly every electronic device. With simulation, designers can evaluate their ICs against several requirements, including power consumption, thermal, and parametric yield. In addition, Ansys RedHawk-SC is uniquely equipped to provide comprehensive multiphysics analysis, revealing how different physics will interact to affect the IC’s performance and longevity.

To learn more about integrated circuits, register for our webinar "Thermal Integrity Challenges and Solutions of Silicon Interposer Design."