Quick Specs

Granta MI Enterprise’s ability to securely manage total Material Intelligence for your company offers tangible cost and time savings, all while enhancing your experience with:

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

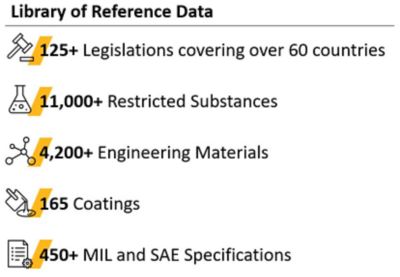

Ansys offers enterprise-wide materials data management software to store, control and analyze, creating your materials' “gold-source.” Granta MI Enterprise is built on the foundation of Granta’s trusted materials reference data.

Industry-leading Material Intelligence for your Enterprise

With 25 years of materials expertise, Granta MI Enterprise brings customers a complete materials data management solution. Empower your enterprise, protect your Material Intelligence and enable digital transformation.

Our unique MI Gateway and Enterprise Connect make way for seamless integration with CAD, CAE and PLM software. From Additive Manufacturing to Composites, we offer cutting-edge material processing.

Rolls-Royce is a global engineering leader, providing highly efficient integrated power and propulsion solutions for a broad range of industry sectors and customers around the world including aerospace and other power systems. They have partnered with the UK-based ANSYS Granta team to implement the GRANTA MI™ software, providing the system to thousands of engineers around the world to create a gold source for Rolls-Royce material intelligence — in turn experiencing real benefits, equated to several millions of dollars a year in time saved, optimization and reduced waste.

Granta MI Enterprise’s ability to securely manage total Material Intelligence for your company offers tangible cost and time savings, all while enhancing your experience with:

Rolls-Royce is a global engineering leader, providing highly efficient integrated power and propulsion solutions for a broad range of industry sectors and customers around the world including aerospace and other power systems. They have partnered with the UK-based ANSYS Granta team to implement the GRANTA MI™ software, providing the system to thousands of engineers around the world to create a gold source for Rolls-Royce material intelligence — in turn experiencing real benefits, equated to several millions of dollars a year in time saved, optimization and reduced waste.

Managing complex and valuable materials data with Granta MI Enterprise improves accuracy and reduces redesign

“Certified savings from the project were over $10M per annum.” Amandeep Singh Mhay, Specialist – Materials Data, Rolls-Royce

Utilizing MI Enterprise, Rolls-Royce provides their civil, defense and nuclear businesses with a “Gold Source” for Material Intelligence. The integration inspired a goal toward zero data loss across the enterprise. The MI Enterprise system has reduced the need for duplicate mechanical testing while offering accurate and traceable data, and minimizing redesign. Ongoing work at Rolls-Royce includes extending the program into composite data management, reducing Restricted Substance risk and improving overall environmental impact.

Rolls-Royce is a global engineering leader, providing highly efficient integrated power and propulsion solutions for a broad range of industry sectors and customers around the world including aerospace and other power systems. They have partnered with the UK-based ANSYS Granta team to implement the GRANTA MI™ software, providing the system to thousands of engineers around the world to create a gold source for Rolls-Royce material intelligence — in turn experiencing real benefits, equated to several millions of dollars a year in time saved, optimization and reduced waste.

July 2025

Ansys Granta MI Enterprise for 2025 R2 introduces enhanced methods for identifying and comparing alternative materials, as well as numerous usability improvements.

This release features enhanced simulation connections with streamlined CAD-to-CAE material assignments, improvements in the Creo integration, and NX-to-ANSA workflow enhancements.

This release offers an enhanced user experience, featuring side-by-side material comparison, improved favorites list management, and expanded sustainability features. These enhancements enable engineers to more easily identify alternative materials, track preferred materials, and make informed decisions within the circular economy.

This release expands the available materials data with new simulation-ready sheet steels for metal forming, updated tapes and adhesives from leading suppliers, a comprehensive composite materials database, and over 5,800 new records across various material types, empowering engineers with broader, more accurate data for advanced simulations.

CAPABILITIES

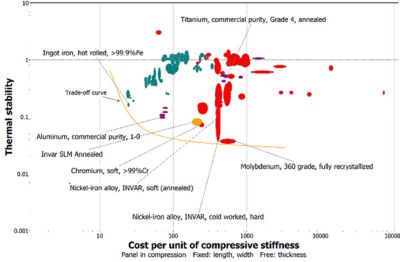

Granta MI Enterprise, the leading system for materials data management, brings a complete material intelligence management solution, allowing you to empower your enterprise, protect your materials and enable digital transformation. Create, control and store valuable materials with our flagship materials properties software. Save time, drive innovation, cut costs and eliminate risk.

Workflow tools ensure the smooth capture, processing and approval of data, information and expertise, and enable users to fully integrate their materials expertise into their business practice. Bring Material Intelligence enterprise-wide with full integration across CAD, CAE and PLM systems.

Manage your company materials knowledge and support business-critical systems with industry-leading Granta MI Enterprise:

Rolls-Royce is a global engineering leader, providing highly efficient integrated power and propulsion solutions for a broad range of industry sectors and customers around the world including aerospace and other power systems. They have partnered with the UK-based ANSYS Granta team to implement the GRANTA MI™ software, providing the system to thousands of engineers around the world to create a gold source for Rolls-Royce material intelligence — in turn experiencing real benefits, equated to several millions of dollars a year in time saved, optimization and reduced waste.

Il est essentiel pour Ansys que tous les utilisateurs, y compris les personnes en situation de handicap, puissent accéder à nos produits. C'est pourquoi nous nous efforçons de respecter les exigences en matière d'accessibilité basées sur le US Access Board (section 508), les règles d'accessibilité des contenus Web (WCAG) et le format actuel du modèle d'accessibilité volontaire des produits (VPAT®).

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.