-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

ANSYS BLOG

June 27, 2022

Why the Time is Right for Hydrogen

“Hydrogen is today enjoying unprecedented momentum. The world should not miss this unique chance to make hydrogen an important part of our clean and secure energy future.”

— Dr. Fatih Birol, Executive Director, International Energy Agency

Dr. Birol's emphasis on increasing the use of hydrogen as the fuel of the present and future comes as we face the realities of global warming. The planet has certainly gotten hotter than its pre-industrial level. According to NASA, the global temperature has risen 1.818 degrees F (1.01 degrees C) since 1880 and continues to trend upward. The Intergovernmental Panel on Climate Change (IPCC), which includes more than 1,300 scientists from the United States and other countries, forecasts a temperature rise of 2.5 to 10 degrees F over the next century. The repercussions of inaction are causing every nation to shiver.

This color-coded map in Robinson projection from NASA displays a progression of changing global surface temperature anomalies. Normal temperatures are shown in white. Higher-than-normal temperatures are shown in red and lower-than-normal temperatures are shown in blue. Normal temperatures are calculated over the 30-year baseline period 1951-1980. The final frame represents the 5-year global temperature anomalies from 2017-2021. Scale in degrees Fahrenheit.

When world leaders from 195 countries met in Paris in 2015, there was an unprecedented agreement to reduce greenhouse emissions and keep global warming under check. They promised to achieve net-zero CO2 emissions by 2050. Following this event, roadmaps were prepared, new policies were announced, and alternatives to supplement fossil fuels were suggested. Hydrogen was a leading alternative fuel. More than 30 countries have released hydrogen roadmaps, and 500+ companies have defined their 2050 targets of hydrogen use. There are more than 200 active hydrogen projects worldwide.

What is so unique about hydrogen? Hydrogen is packed with three times more energy per kilogram than any hydrocarbons (the chief components in petroleum and natural gas), and hydrogen produces zero carbon emissions at the point of utilization. While hydrogen was already gaining attention due to its environmental benefits, a jump of around 45% in European gas prices over the past few months has made hydrogen cost-competitive about a decade ahead of schedule. Ambitious plans are being worked upon to make hydrogen a viable substitute for fossil fuels in manufacturing, transportation, and heating.

Challenges in Working with Hydrogen

Using hydrogen as a fuel seems so attractive because burning hydrogen only produces water. So, what is holding us back from moving to hydrogen use completely? Plenty. The most basic challenge is coming from the fact that it has less than a third energy per unit volume compared to natural gas. The poor volumetric energy density is creating issues in using hydrogen as a fuel. Not only this, but there are also challenges in all aspects: production, storage, transportation, and utilization.

Hydrogen Production Challenges

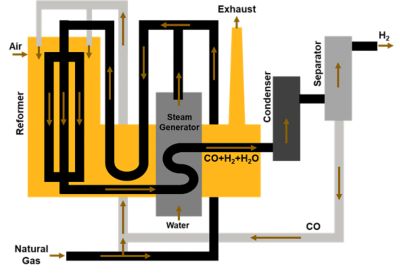

Today, most of the hydrogen is produced using the steam methane reforming (SMR) process. In this process, natural gas and steam reforms on a nickel catalyst at around 850 degrees C. This process has higher yield efficiency (the unit of input required to produce a unit of output ) of 75% to 80%. However, this way of producing hydrogen, also known as grey hydrogen, leads to emissions that are higher than those from simply burning the fossil fuel and so would be detrimental to the environment.

The steam methane reforming process produces grey hydrogen.

Blue hydrogen is an industry term for hydrogen produced from natural gas and supported by carbon capture and storage. Hydrogen is labeled blue whenever the carbon generated from steam reforming is captured and stored through industrial carbon capture and storage.

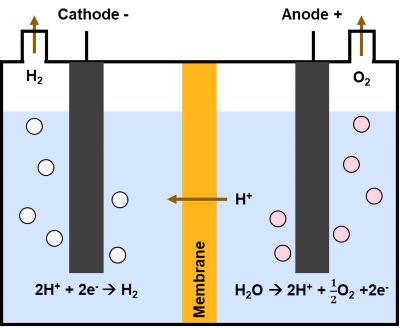

For long-term sustainability, we need a cleaner way of producing hydrogen, such as electrolysis. In this process, water is split into hydrogen and oxygen gas by passing an electric current through it. Hydrogen produced this way is commonly referred to as green hydrogen, as there are no emissions adversely affecting the environment. A schematic of electrolysis process is shown below.

The electrolysis process can produce green hydrogen.

To make electrolysis a viable solution for hydrogen production, we need to switch to low-cost renewable energies, such as solar power or wind energy. Hydrogen produced in this way is commonly referred to as green hydrogen as there will be no emissions adversely affecting the environment. Today, less than 5% of all hydrogen produced is green hydrogen. The transition from grey hydrogen will still take few decades to bring green hydrogen to parity with grey hydrogen in terms of volume and cost of production. As per the Hydrogen Council report, "Hydrogen Decarbonization Pathways: Potential Supply Scenarios," it is expected that the tax levied on production of grey hydrogen will increase significantly, which would make its production less affordable.

Hydrogen Storage and Transportation Challenges

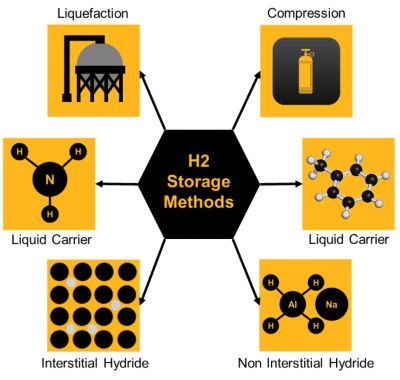

The next set of challenges involve how we move and store hydrogen. Currently, most hydrogen is produced onsite and all of that is utilized at the point of manufacture. Transporting hydrogen is still a costly affair owing to its low density and hence its applicability is not widespread as of today. However, there are plans being put in action to allow transport of hydrogen in gaseous or cryogenic form or combine it with metals and then transport it to the site of utilization so it can be easily retrieved. This way hydrogen as a fuel could be used in other applications across industries. The figure below lists the most common methods of hydrogen storage.

Common methods of hydrogen storage.

However, there are certain characteristics of hydrogen that need to be considered during storage and transportation. Hydrogen is far lighter than fossil fuels, and also prone to leaking. Its high flammability limit combined with low-ignition energy requirements and high flame speed poses dangers of auto-ignition and explosion. Therefore, we need newer, safer, and more durable methods to store and transport hydrogen. This should also include lower cost-per-unit mass and easier-to-handle methods.

Hydrogen Utilization Challenges

In principle, hydrogen can be used as a fuel in any combustor or in fuel cells. In combustion applications, it is seen as an efficient fuel due to its higher flame speed, wider flammability limit, and zero toxic emissions. However, its higher adiabatic flame temperature (the temperature that results from a complete combustion process) and flame flashback pose major challenges, as these features can enhance oxides of nitrogen (NOx) generation and reduce the life expectancy of combustors. There is still a need to understand the complex combustion behavior of hydrogen from a safety point of view.

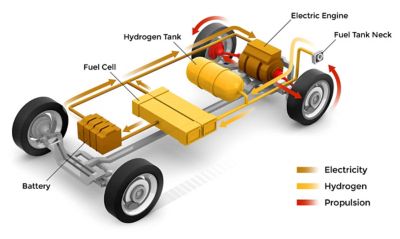

In fuel cell applications, hydrogen-based fuel cells release zero emissions, operate quietly, offer no charging issues, and have good thermal efficiency (up to 60%). Overall, a combination of fuel cell and electric motor (about 45% efficient), could be a better choice compared to a high-performance diesel engines or a gas turbines (both also about 45% efficient). However, due to lack of adequate infrastructure and requirements for larger fuel tanks, fuel cells are not growing at as swift a pace as we might like.

Diagram of a fuel cell electric vehicle showing how hydrogen and oxygen generate electrical energy that is used to power the electric motor and/or battery.

How Simulation can Help

To accelerate the adoption of hydrogen, we need to understand every aspect of a hydrogen economy and its life cycle. But first of all, we should be ready to accept that our current knowledge about the hydrogen life cycle is more theoretical. We need to “channelize” this knowledge toward real-world industrial applications. We must overcome the challenges discussed above on a fast track to realize the potential of hydrogen, and simulations are integral part of this exploration.

Simulations are critical to assessing the performance of devices in SMR plants, analyzing the performance of electrolysis, performing safety analysis, studying the performance of different storage methods, understanding combustion characteristics, and more. The value of simulation is already proven for high-fidelity virtual validations. Simulation can provide insights on every aspect of performance that helps in making critical decisions. It is a must-have to deploy hydrogen across industries and the best way to rapidly test and adjust all different hydrogen innovations.

Over the past few decades, engineers have moved toward simulation tools for virtual prototyping and a simulation-based design process for using hydrogen in combustors. This digital workflow starts before the first physical prototype is manufactured, which can save significant time and costs. For example, simulation of the hydrogen combustion process has revealed flame flashback, which can adversely harm components. To get past this obstacle, engineers have simulated the combustion of hydrogen-based fuel blends, and the results are already very encouraging.

Simulations are helping engineers to derive blend composition that can avoid conditions like flame instabilities, flashback, and other obstacles for given designs and operating conditions. It is also helping to design and evaluate different design concepts like micro-mixing and axial air injection to mitigate undesired performance.

Another area where simulation is heavily used is the prediction of hydrogen autoignition due to the sudden rupture of storage tanks. This is very important to ensure safety during handling and long-distance transportation. The picture below shows a successful ignition at 250 bar due to a rupture. In a similar study at 50 bar, no ignition was observed. Such information helps in tank redesign.

Successful ignition and no ignition

On the hydrogen utilization front, designers rely on simulation of fuel cells rather than actual experiments. Fuel cells are an alternate technology to harness the energy stored in hydrogen. This is distinct from the traditional combustion process of fuel, where energy is directly available in the form of electrical energy rather than thermal energy. Proton exchange membrane fuel cells (PEMFC) are the most widely utilized technology for automotive applications. The reliability of PEMFC is directly affected by the water content, temperature, and gas species concentration; hence, knowledge of the physical processes is necessary for better design and control.

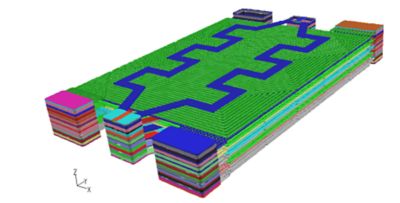

A fuel cell model

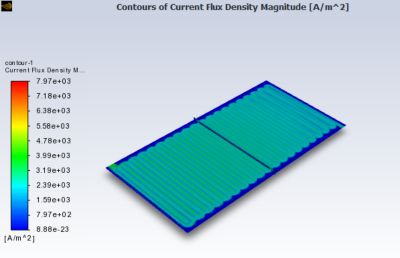

The spatial distribution of various physical parameters is difficult to measure through experiments. However, computational fluid dynamics (CFD) simulations can capture the complete 3D fields of interests. The picture below shows the distribution of currents through the membrane of the fuel cell. The nonuniformity of the current is observed toward the ends, which is an important insight for the designer in improving the fuel cell’s design.

Simulation showing the distribution of currents

Based on the sustainability vision of some of the top companies, hydrogen faces stiff competition in the transportation industry. The world has already seen Toyota launch its first hydrogen-powered vehicle, Mirai, way back in 2015. However, there are only about 20,000 hydrogen-powered automobiles in the world, compared to 20 million electric vehicles. Airbus has revealed its plans to move toward zero-emission hydrogen aircraft by the end of 2035. We have also seen the launch of first hydrogen carrier ship in Japan, and Kawasaki Heavy Industries is welcoming the world’s first liquefied hydrogen receiving terminal.

The human race has seen many ups and downs, and each time we have bounced back with stupendous improvements in technological advancements. This time the challenge is indeed daunting, as climate change as the result of global warming has the capacity to severely affect life on the planet as we see it now. While we have less time to correct our mistakes, a new world economy based on hydrogen backed by proper policies, increase research and development, and a firm focus on our overall objective can achieve our goals.

In future parts of this series, we will take a closer look at the hydrogen-based combustion process, electrolysis, and fuel cell modeling.

Learn more about how Ansys customers are using simulation to respond to climate change in Earth Rescue, an Ansys online video series.