-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

ANSYS ADVANTAGE MAGAZINE

DATE: 2019

Framing a Lighter, Stronger Race Car

By Paolo Bosetti, Professor, Department of Industrial Engineering, University of Trento, Italy

Engineering student teams in universities around the world compete in the Formula SAE (FSAE) competition to build a race car, giving them an opportunity to apply their engineering knowledge, in a practical and fun way. The E-AGLE Trento racing team takes advantage of Ansys additive manufacturing solutions and topology optimization in Ansys Mechanical to design a car that is lighter, has stronger joints and is easier to build than a typical FSAE car.

For the E-AGLE Trento racing team at the University of Trento, Italy, Formula SAE is not just about the race — it is also about implementing a groundbreaking idea for the design and manufacture of the vehicle frame. Working closely with the Ansys technical support team, they performed simulations using Ansys Workbench Additive (part of Ansys Additive Suite) to produce an innovative frame joint that relies more on the mechanical properties of the materials and less on a potentially weaker weld for its strength. The joint also makes the manufacturing phase easier by minimizing the need for external dies or fixtures to hold components in place during the welding phase. Workbench Additive enabled the team to make a traditionally weak part of the frame — the so-called “hard point,” where the suspension is attached to the car frame — an integral part of the 3D-printed joint instead of consisting of a metal tab welded to the outside of the joint. By eliminating this typically weak point, the team made the vehicle frame more rigid and less susceptible to breakage during a race. Finally, topology optimization using Ansys Mechanical helped them to reduce the mass of one component of the car by 55 percent.

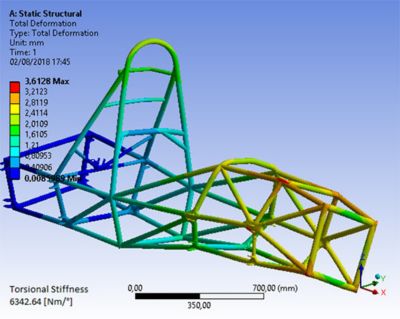

FSAE car frame with increased torsional stiffness due to 3D-printed joints

ORIGINS

The E-AGLE Trento team was formed in 2016 under the direction of faculty from the University of Trento. Realizing that they would need to use additive manufacturing for some components of the race car they planned to build, the team partnered with the industrial development company Trentino Sviluppo, which is owned by the local government and funded by the EU, and its facility for prototyping mechatronics systems, named ProM. The latter is managed by Trentino Sviluppo SpA, the University of Trento and the Bruno Kessler Foundation, with some help from Confindustria Trento.

This partnership was a win–win arrangement. The E-AGLE Trento team needed to use ProM’s 3D printers, laser cutters and other leading-edge equipment. ProM needed a first test case to demonstrate their capabilities to the market. The FSAE car project was an ideal test case.

ENGINEERING THE BASICS

The team started with an open-frame design instead of the monocoque design used by many teams in the competition. The open-frame design focused the engineering challenge on designing the best configuration of metal tubes and joints. The overall goal was to determine the high-level geometry of the frame by optimizing a parameter defined as the torsional stiffness of the car frame divided by the weight of the frame.

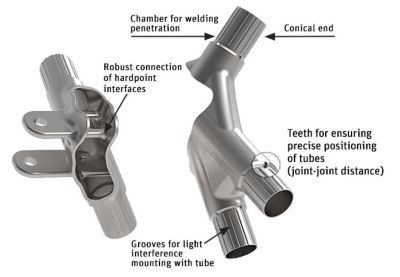

3D-printed joint for greater strength and torsional stiffness

With a wide range of variables possible for the diameters, thicknesses and relative positions of joints between three tubes in the car frame, student engineers performed parametric studies using Ansys Mechanical within the Ansys Workbench environment to investigate all the options. Finding the optimal cross sections and thicknesses of tubes at each point in the frame was critical to strengthening the frame at points of high stress while minimizing the total weight of the frame. Parametric simulation studies enabled the students to determine the optimum configuration of each tube and joint in a fraction of the time it would have taken them had they been limited to traditional manual iterations.

Close-up view of an assembled car frame section showing a four-way joint with integral hard point connectors

GETTING DOWN TO DETAILS

E-AGLE Trento team engineers wanted to go beyond merely designing a satisfactory FSAE car frame — they aspired to introduce a revolutionary element that would greatly improve the strength and manufacturability of the vehicle. This innovative element would be the frame joint. This is the point at which three or more frame tubes intersect to form a corner. Traditionally, the tubes are simply welded end-to-end to form the joint, but welds can be weak points in a frame. Using Ansys Mechanical and Workbench Additive, the engineers concentrated on making a frame joint whose strength depended more on the mechanical properties of the metal and less on the weld itself. They also incorporated the hard points of the suspension connections into the 3D-printed joint to eliminate another weakness.

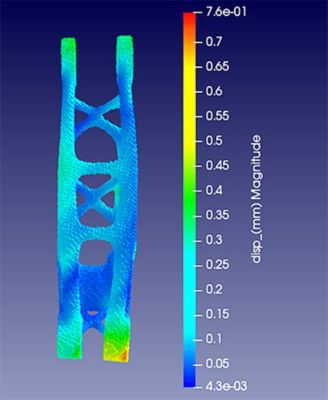

Bellcrank designed using ANSYS topology optimization, which reduced the weight of the part from 345 g to 220 g, a decrease of 37 percent

Having already determined the optimal frame tube dimensions, they used Workbench Additive to design the joint with a slightly larger diameter so that the joint ends would fit inside the tails of the frame tubes. The resulting inner joint has a set of longitudinal crests that are designed to contact with the outer frame tube. This ensures that the mechanical stresses between tubes and joints are mainly sustained by the mechanical fit of the joints in the tube rather than by the subsequent weld. The end of the frame tube has a slight chamfer to accommodate the welding alloy. Small, tooth-like protrusions spaced at regular intervals along this chamfer ensure the right distance between the tube and joint. This very precise relative positioning of tubes and joints has two big advantages:

- Only a single die is needed during assembly of the car frame. This single die helps join the main hoop of the car frame with the rear part of the vehicle during welding. FSAE regulations stipulate that the main hoop has to be one single tube, so it cannot be joined, only welded. Assembly of the rear part of the car frame requires no dies because the structure is fixed by precise positioning of tubes relative to joints. This arrangement enables welding precision and greatly reduces the welding time needed for the whole car frame.

- The resulting frame is much more robust and rigid when compared with a purely welded open-space frame design.

"Using topology optimization, student engineers reduced the bellcrank’s mass from 345 g to 220 g, a 37 percent reduction."

LIGHTWEIGHTING COMPONENTS

Reducing weight is an obvious way to make a car quicker in acceleration and able to go faster while consuming the same amount of fuel — critical to any race car. E-AGLE Trento engineers used topological optimization with Ansys Mechanical to redesign three components that were initially made of solid metal: the bellcrank, the suspension rockers and the steering support mechanism. Topology optimization automatically determines where material should exist within a given volume so that loads and stresses can be efficiently managed when the part is loaded. The resulting framework has open spaces where no material is needed and thicker struts where stresses are high. Overall, topology optimization reduces the weight of each component. In this case, the student engineers reduced the bellcrank’s mass from 345 g to 220 g, a 37 percent reduction. For the steering support, they reduced the mass by 55 percent, from 450 g to 210 g.

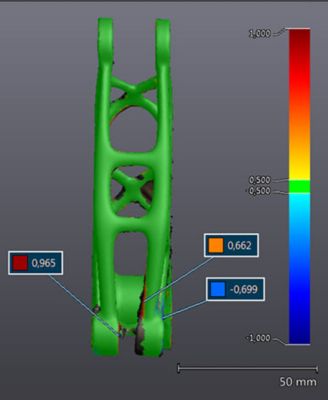

COMPENSATING FOR THERMAL DEFORMATION IN ADDITIVE MANUFACTURING DESIGNS

Powder-bed metal additive manufacturing involves adding layers of material and heating them with a laser to fuse the powder. This heating and cooling can result in deformations, which will result in a non-ideal shape. The E-AGLE Trento team used Ansys Workbench Additive to simulate the amount of thermal distortion before performing the 3D print run so they could adjust the geometry of the part to compensate for the distortion. While distortion still occurred, it happened in a predictable manner that was taken into account by the modified geometry. The resulting part met specifications exactly.

Simulated thermal distortion of FSAE car component

Measured thermal distortion of actual physical component

COOPERATION WINS THE RACE

By working closely with the Ansys technical support team, E-AGLE Trento student engineers learned how to use Workbench Additive and Ansys Mechanical efficiently and effectively to design a groundbreaking frame design for their FSAE car. The car is lighter and stronger with increased torsional stiffness, which should lead to higher speeds, reduced wear and greater safety.

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기