Case Study

-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

“Product development can be significantly accelerated through the early use of simulation. In particular, the combination of Ansys Discovery's fast GPU solver with systematic parameter studies allows us to make well-founded decisions on our cooling design. The approach we have developed in cooperation with CADFEM allows us to better understand the possible variants and we can justify our configuration to the customer much more easily.”

— Kai Schneider, Development Engineer / Wittenstein cyber motor

The combination of an extremely fast graphics processing unit (GPU) solver, powerful geometry modeling capabilities, and systematic parametric design studies accelerates development of cooling designs for electric motors. With support of Ansys’ channel partner CADFEM, Wittenstein leveraged Ansys Discovery, Ansys optiSLang, and Ansys Fluent to develop cooling systems more efficiently.

Challenges

General requirements for the development of electric machines pose a major challenge for designing cooling concepts. High performance and a wide temperature range combined with the need for small installation space make highly integrated cooling designs indispensable. Simulation helps ensure heat dissipation and thermal integrity during development. However, a conjugate heat transfer simulation with conventional tools is computationally time consuming. Because of the time required, this simulation type is rarely used for optimization, in which hundreds of variants are calculated. With hard-to-achieve requirements, it is therefore impossible to ensure that a good design can be found in sufficient time.

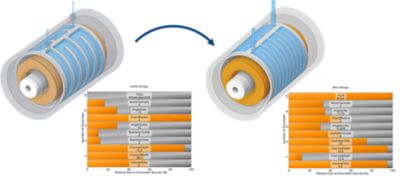

Initial design versus the final, optimal design (© Wittenstein; CADFEM Germany)

Engineering Solution

- Conjugate heat transfer (CHT) simulation is used to analyze the thermal interaction between fluid and structure. With Discovery’s live GPU solver, different cooling concepts can be investigated and compared in the early design phase.

- Discovery’s geometry modeling capabilities are not only limited to quick geometry modification, but also include a Python scripting feature. This has been used by Wittenstein's long-standing partner for Ansys, CADFEM, to automate geometry creation, simulation setup, and post-processing, which enables Wittenstein engineers nearly limitless geometry variation in a robust, fast, and flexible manner. The script covers a large variation range that is controlled by 14 parameters.

- Parametric design studies are leveraged to understand the design by investigating parameters and their effect on the results. This helps systematically optimize for minimum system temperature in compliance with pressure loss requirements.

- Optimizing with several hundred design variants can be completed in a short amount of time because the Discovery Live solver only needs minutes instead of days per variant. The best design is validated with flagship CFD solver, Fluent.

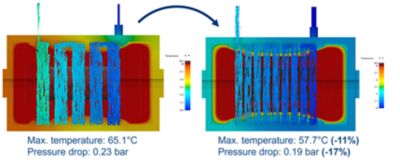

Temperature flow plots of the initial design (left) to the final design (right) © Wittenstein; CADFEM Germany

Benefits

- In the specific application, a heat output of approximately 10 kilowatts (kW) had to be cooled, with one operation condition already close the coolant’s boiling point. Compared to the first variant, the maximum fluid temperature was reduced by 10%, and the strict pressure drop requirement was fulfilled by reducing the pressure loss by about 50%.

- Development time was reduced due to frontloading the simulation. Instead of an iterative approach, in which a design engineer works out a finished design that is only later evaluated by simulation, the physical behavior is considered from the beginning.

- It was possible to understand dependencies and the influence of parameters (e.g., number of channels, channel width, etc.), back up design decisions with quantified facts, and justify the design to customers as well.

- The company performed targeted optimization under the consideration of different requirements.

- The workflow, developed by CADFEM, is easy to set up in Ansys. It can also be transferred to other areas and applications with few adjustments.

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.