Engineering What’s Ahead:

ELECTRIFICATION

The race to electric mobility is on:

Find out how pioneers like VW Motorsport, Subaru and A123 are using simulation to win the race by downloading the ebook.

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Find out how pioneers like VW Motorsport, Subaru and A123 are using simulation to win the race by downloading the ebook.

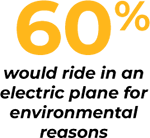

Winning the race means reducing cost, overcoming range and payload anxiety, delivering performance, and addressing safety and cybersecurity concerns. Simulation is the key to solving the most critical engineering challenges of battery and battery management systems, power electronics, electric machines and powertrain system integration. Quantified results include:

Download the free e-book to find out how companies like NEVS, Zunum Aero, magniX, and Integrated Micro Electronics are applying simulation to achieve outcomes like this.

1. Data collected through a consumer survey. Ansys enlisted Atomik Research and its team of MRS-certified researchers to conduct the online survey in March 2020. The sample included 16,037 adults 18-and-over, from the U.K., U.S., DACH (Austria, Germany and Switzerland), France, Sweden, Japan, China and India. See more survey results at https://www.ansys.com/campaigns/electrification-survey

2. https://www.ansys.com/en-in/about-ansys/advantage-magazine/volume-xi-issue-2-2017/electrifying-vehicle

3. https://www.ansys.com/-/media/ansys/corporate/resourcelibrary/casestudy/sherlock-danfoss-case-study.pdf

4. https://www.youtube.com/watch?v=GpJaVUs0UH4

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.