-

-

Accédez au logiciel étudiant gratuit

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

-

Connectez-vous avec Ansys maintenant !

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Pays et régions

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

Produits & Services

Apprendre

À propos d'Ansys

Back

Produits & Services

Back

Apprendre

Ansys donne les moyens à la prochaine génération d'ingénieurs

Les étudiants ont accès gratuitement à un logiciel de simulation de classe mondiale.

Back

À propos d'Ansys

Concevez votre avenir

Connectez-vous à Ansys pour découvrir comment la simulation peut alimenter votre prochaine percée.

Espace client

Support

Communautés partenaires

Contacter le service commercial

Pour les États-Unis et le Canada

S'inscrire

Essais gratuits

ANSYS BLOG

December 27, 2023

Mining and Resource Recovery from Desalination and Industrial Brine

Brine is a saline byproduct waste stream produced from desalination plants and several industrial processes (such as oil and gas, petrochemical, pharmaceutical, textile production, aquaculture, etc.) that is often rich in desirable minerals and metals. Brine mining is a promising approach for recovering valuable resources such as lithium, a critical element for battery manufacturing, as well as boron, magnesium, potassium, and other minerals that are of high economic value for various industries. However, technology developers need to understand the environmental and techno-economic shortcomings of evaporitic techniques to achieve sustainable and cost-effective brine mining and resource recovery technologies.

What is Evaporitic Brine Mining?

Evaporitic brine mining includes evaporating water out from the brine until solid products precipitate, which are then collected. Quantifying the evaporation process, in addition to identifying when and how the products solidify, is essential for optimizing the brine mining process. Examples of evaporitic techniques include humidification-dehumidification desalination (HDH), convection-enhanced evaporation (CEE), and other thermal-assisted methods for brine concentration. Developing these technologies in a sustainable way and bringing them into the market require performance and cost modeling, design optimization, and operation monitoring, which can be accomplished through simulation and digital engineering.

Sustainable Solutions for Evaporitic Brine Mining

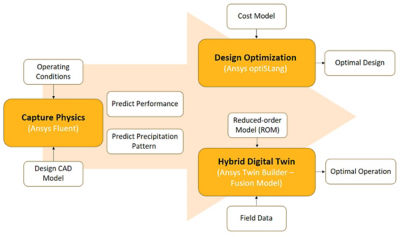

Ansys Fluent offers high-fidelity computational fluid dymanic (CFD) simulation, which can be utilized to predict evaporation rates and element precipitation/solidification pattern based on design and operating condition while accurately capturing the physics, including phase change, surface tension effects, critical operating factors, and more.

Once a predictive simulation is developed, engineers can use Ansys optiSLang to combine performance prediction models with cost models to perform sensitivity analysis and optimize product design. Optimization is a powerful tool to maximize performance while minimizing costs and reducing product development time, which are critical factors for achieving a successful brine resource recovery process.

Finally, brine mining processes need to be continuously monitored to maintain the desired economic and environmental performance. In this space, Ansys Twin Builder offers solutions for creating and deploying hybrid digital twins that can combine sensor data collected from the field with reduced-order models (ROMs). These further enhance model prediction by capturing unresolved physics and uncertainties, which in turns enable predictive maintenance and industrial asset management.

So, brine mining is critical for recovering resources from waste brine and achieving a sustainable circular economy. Ansys offers solutions for simulation, optimization, and creating digital twins of brine mining processes to help engineers achieve cost-optimal designs and operations.

Ansys tools workflow to automate design processes and enhance brine mining operations.

Reducing Production Time and Costs in the Salt and Potash Industry

K+S AG, which is one of the world’s largest suppliers of fertilizers and industrial salts, used Fluent to boost the efficiency of the salt and potash industry and support their sustained increase in competitiveness. K+S AG uses a cooling pond technology for recovering crystalline potassium chloride (KCl), which is an important mineral fertilizer and serves as a raw material for a wide range of industrial products (plastics, pharmaceuticals, etc.).

Using Fluent, they developed a time-dependent (transient) simulation model to better understand operating processes and cause-and-effect mechanisms. This led to answers for several critical questions, including the quantity and the composition of the crystallized salt being produced and the effect of climatic conditions such as temperature, humidity, and wind speed on the production process.

Cooling pond of the K+S mine in Saskatchewan, Canada

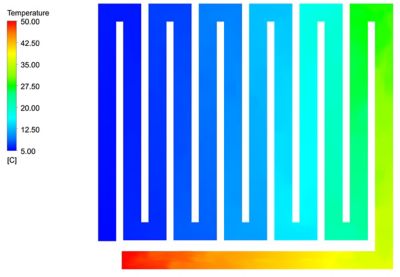

Temperature development over a cross-section of the cooling pond

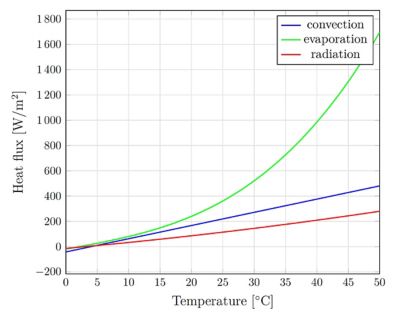

The crystallization process is a complex phenomenon that includes mass transfer between two phases and multimode heat transfer mechanism (convection, radiation, evaporation). K+S AG engineers were able to model the multiphase interactions, temperature, and concentration-dependent solubility and fluid characteristics — which are critical in the crystallization process — with the help of Fluent models and user-defined functions (UDFs). UDFs are able to expand software capabilities in order to manage client-specific issues.

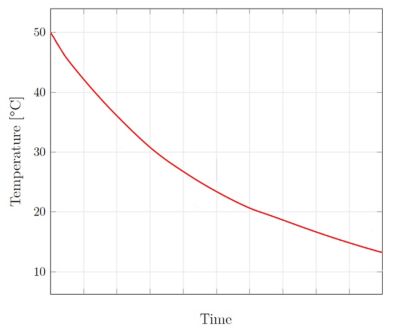

The Fluent model allowed them to simulate the cycle of seasons and the monthly fluctuation in temperature and their effect on the solubility of the components. The model provided a comparative analysis of different pond designs as a function of various climate scenarios, enabling the company to analyze and optimize proposed projects at early stage to improve the production efficiency at K+S, as well as keep production times and costs at minimal rates.

Temperature behavior of the cooling pond under characteristic climate conditions

Heat flows generated by convection, evaporation, and radiation under average annual climate conditions