-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

“One word: plastics.”

If the enthusiastic character from the 1967 film “The Graduate” had known then what we know now, he might have had more than one word to say to young Dustin Hoffman. It turns out that plastics have lingered in the environment for even longer than the line for which the movie is so well remembered.

Unlike the movie, plastics have not lingered in a good way. Some types of plastics can be recycled while others cannot. With less than 10% of plastic recycled, most plastic products either are incinerated via open burn or end up in landfills, where they will decompose over the course of eons. Others are simply discarded into the environment and find their way into watersheds. Most plastic chemicals are not chemically bound to polymer matrices. Instead, they are physically blended into polymers and can be released from plastic into the environment by leaching, volatilization, or abrasion, then enter the human body via ingestion, inhalation, or dermal absorption.

The British medical journal The Lancet paints a stark picture of our plastic consumption:

- Half of all plastic ever made has been produced since 2010.

- China is the largest producer of plastics (208 megatons), followed by North America (71 megatons) and the European Union (66 megatons).

- North America, the European Union, and China use 195 kg, 187 kg, and 138 kg of plastic per person per year, respectively.

- Single-use plastics (for example, packaging material) account for 35% to 40% of current plastic output and 65% of discarded plastic.

Researchers estimate that more than 8 billion metric tons of plastic waste now pollute the planet — approximately one ton per person — and that waste can be found everywhere from the top of Mount Everest to the lowest reaches of the Mariana Trench. The United Nations (U.N.) Intergovernmental Negotiating Committee has been trying to develop a legally binding, internationally agreed-upon instrument to address plastic pollution, but its meeting in August 2025 concluded without a final consensus.

In the absence of a binding agreement or guidance from the U.N., the question remains: What steps can proactively reduce the negative impact of plastics?

Do More With Less

One way to reduce plastic pollution is to use less plastic in products. Regardless of the manufacturing techniques used to produce plastic components, products made with less plastic still need to meet varying design requirements, including structural integrity, durability, size and envelope specifications, weight, and cost.

Tools from Ansys, part of Synopsys, enable engineers to simulate components and manufacturing processes, giving them insight into process and product performance among varying types and amounts of plastic. These include:

- Ansys Mechanical structural finite element analysis (FEA) software

- Ansys Polyflow polymer processing simulation software

- Ansys optiSLang process integration and design optimization software

Advanced materials modeling, for example, enables engineers to understand flow and deformation behavior in the molding of components made with different plastics or thinner structures. Using simulation can accelerate insight while eliminating the waste associated with producing physical prototypes that ultimately won’t meet consumer needs.

Blow molding simulation in Ansys Ployflow polymer processing simulation software

Improving Materials Sourcing

Today, more than 16,000 polymers, additives, and residual processing aids are used in the manufacturing of plastics. Seventy-five percent of plastic chemicals have not been tested for safety, so their impact on human health and the environment is not well known. Further, more than 4,200 substances are considered chemicals of concern for their toxic effects, persistence, and bioaccumulation. Materials intelligence tools, such as the Ansys Granta MI materials intelligence platform, can provide engineers and chemists with greater insights into the characteristics of the materials used in products, including suitable alternative choices for per- and polyfluoroalkyl substances (PFASs), known as “forever chemicals.”

The Granta MI platform can also help identify and track the material properties of raw materials sourced from different suppliers, which can be particularly challenging when similarly named polymer grades from suppliers can have significantly different material properties. One cleaning equipment manufacturer used the Granta MI platform to gain insights into the material properties of polymers sourced from more than 100 suppliers. With deep insight into the properties of these products — and with the Granta MI platform connected to its material examination ordering system — the company made informed decisions about which polymers it wanted to use, how it might safely and reliably substitute one for another, and how it could ensure manufacturing consistency across 20 production sites scattered around the globe.

Refining Recyclability

Many organizations are looking for ways to use recycled plastic rather than creating components from virgin plastic. One issue with recycled plastics, though, is that the material composition of a given batch of plastic is often unknown. This lack of insight creates challenges, particularly if organizations want to create products or components with consistent properties.

Using Ansys software, an automobile parts manufacturer developed a methodology and workflow system designed to overcome these unknowns. Using Granta MI software, Ansys SpaceClaim 3D computer-aided design (CAD) modeling software, optiSLang software, and Ansys LS-DYNA nonlinear dynamics structural simulation software, the company deployed a workflow that enables it to design and manufacture high-quality automobile parts despite starting with recycled source materials. As a result, it produced reliable parts that ultimately reduce demand for virgin plastic and the amount of used plastic that might otherwise end up in a landfill or incinerator.

Other aspects of recycling also benefit from the work of organizations using Ansys tools. One of the fundamental challenges in plastics recycling lies in the process by which plastic waste is culled from the stream of materials collected for disposal. In many locations, the process of sorting plastic waste is highly labor-intensive and expensive, yet sorting is crucial because different types of plastic must be recycled in different ways.

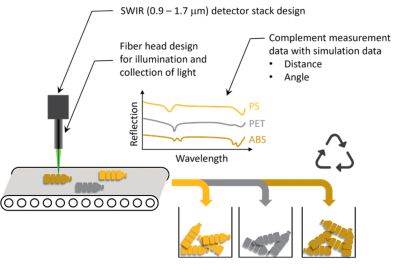

Developers working on an innovative short-wave infrared (SWIR) sensor relied on Ansys Lumerical opto-electronics component simulation software and optiSLang software to improve the design of a sorting solution intended to autonomously identify the composition of individual pieces of plastic waste based on how they reflected light. Simulation enabled fast, accurate analysis of different designs, which helped the developers optimize the solution for accurate results. As a result, the enhanced SWIR-based detection system has reduced sorting errors, improved the efficiency of autonomous sorting solutions, reduced the cost of recycling plastics, and, by increasing the amount of plastic that can be properly recycled, decreased the need for virgin plastics.

A short-wave infrared (SWIR) sensor-based sorting solution is designed to autonomously identify the composition of individual pieces of plastic waste based on how they reflect light.

The Wrap on Plastics

We won’t be living without plastic products anytime soon. More than merely convenient, many plastic products are essential in our daily lives. Companies can, however, take steps to ensure that the plastics they produce and use are developed safely and disposed of properly. By reducing the amount of virgin plastics required and increasing the amount of recycled plastics they use, companies can help create a healthier world.

Learn more about how Ansys can help with your sustainability efforts.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.