Quick Specs

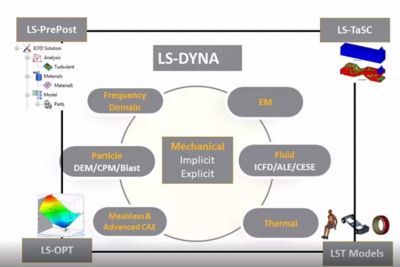

LS-DYNA delivers a diverse array of analyses with extremely fast and efficient parallelization.

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Students get free access to world-class simulation software.

Connect with Ansys to explore how simulation can power your next breakthrough.

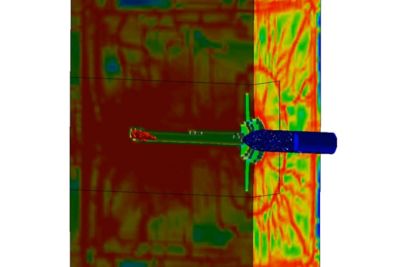

Ansys LS-DYNA is the industry-leading explicit simulation software used for applications like drop tests, impact and penetration, smashes and crashes, occupant safety, and more.

Ansys LS-DYNA is the most used explicit simulation program in the world and is capable of simulating the response of materials to short periods of severe loading. Its many elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem. Ansys LS-DYNA applications include:

Watch this video for an introduction to Ansys LS-DYNA – the most scalable multi-physics solver. LS-DYNA empowers users with it's fast and accurate predictive engineering capabilities for an endless list of potential applications.

LS-DYNA delivers a diverse array of analyses with extremely fast and efficient parallelization.

July 2025

With the 2025 R2 release of Ansys LS-DYNA, material assignment, structured S-ALE meshing, and enhanced postprocessing for batteries and electromagnetics (EM) are introduced.

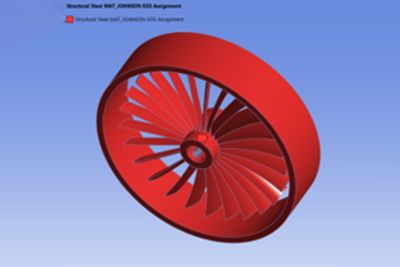

Assign materials directly to bodies in Ansys Mechanical, avoid duplication with automatic reuse of material cards, and streamline model setup using command snippets—making your simulation workflow faster, more consistent, and easier to manage.

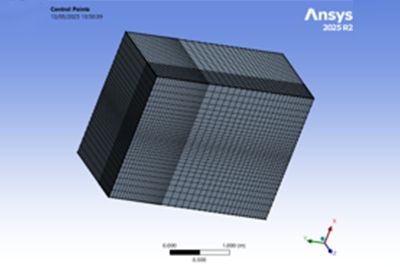

Generate high-quality 2D or 3D structured meshes using control points, visualize them directly in Mechanical, and access advanced solver options—supporting the full range of meshing capabilities at the pre-processing stage for greater accuracy and control.

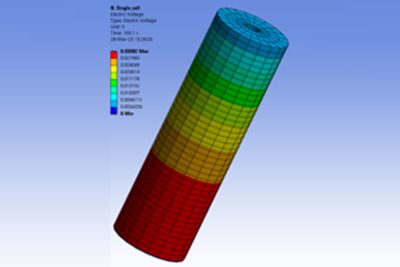

Postprocessing is now supported for both Batmac and Solid battery models. Electromagnetic results and battery-specific outputs are available directly in Mechanical as user-defined results, enabling deeper insight and easier visualization through Solution, View, and Worksheet tools.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

Using simulation, doctors can determine the magnitude and location of brain strains, enabling them to improve concussion treatment.

By applying an LS-DYNA simulation-based workflow, clinicians can obtain a player’s acceleration level and convert that into strain levels across different parts of the brain.

Clinicians are unclear about how to measure the damage incurred by head impacts. Concussions diagnosed by magnetic resonance images (MRIs), computed tomography (CT) scans and blood tests often deliver inconclusive results.

Dr. Michael Power leads clinical care at Beaumont Hospital in Dublin, Ireland, which specializes in the treatment of head injuries — many of which occur during contact sports. Several years ago, he aligned with CADFEM Ireland — Ansys’ channel partner in Ireland — on a mission that would combine engineering simulation with clinical expertise to research the mechanisms of concussion. They sought to understand whether simulation software could help define the causes of concussions, reduce their number and improve concussion treatment.

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

LS-DYNA CAPABILITIES

Engineers can tackle simulations involving material failure and look at how the failure progresses through a part or through a system. Models with large amounts of parts or surfaces interacting with each other are also easily handled, and the interactions and load passing between complex behaviors are modeled accurately. Using computers with higher numbers of CPU cores can drastically reduce solution times.

LS-DYNA elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem.

LS-DYNA RESOURCES

Join us in person on November 15-16 in Novi, Michigan, for an exciting 2-day forum as we showcase keynotes, dozens of user presentations, and networking opportunities with hundreds of expert LS-DYNA users to help accelerate cutting-edge innovation with the user community.

The European LS-DYNA Conference will be held in Baden-Baden, Germany on October 18 and 19 2023. With about 200 technical presentations, top-class keynotes, an accompanying exhibition and numerous international participants from industry and academia, the conference is the central event around LS-DYNA in Europe.

LS-DYNA RESOURCES

Join us for this webinar to understand battery behavior under normal operating conditions and abuse conditions to optimize battery designs with Ansys LS-DYNA.

In November 2019, Ansys acquired LSTC, the authors of the explicit finite element code LS-DYNA. Ansys LS-DYNA is the most used explicit simulation program, capable of simulating the response of materials to short periods of severe loading.

This webinar presents the use of Ansys LS-DYNA for predicting the vibration caused by trains based on wheel and rail roughness modeling.

Discover how using Ansys LS-DYNA and Ansys optiSLang in tandem meets rising automation demands by joining powerful solvers and providing an opportunity to map and share data between them for advanced optimization and sensitivity investigation.

Learn about the unique capabilities and features of LS-DYNA to efficiently model impact and drop tests.

In this webinar, the BatMac model will be presented along with the test setup and model development. Additionally, capabilities, limitations and future improvement of the battery safety modeling are discussed.

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.