-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

August 4, 2023

Understanding Discrete Element Method

How Does DEM Work?

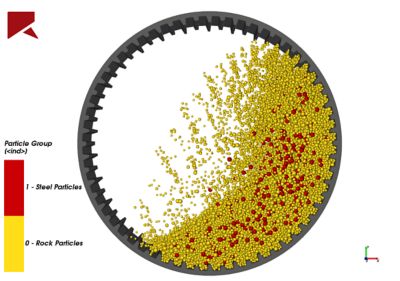

The fundamental working principle of every DEM code is to detect particle collisions and compute the contact force. This is achieved using the soft-sphere method, where particles are rigid, and any deformation at contact is modeled as an overlap. DEM methodically tracks each particle in the domain, facilitating the prediction of each particle's position at the next time step.

Importance of Particle Shape in DEM

The flow of particles can be significantly affected by their shape. While spheres allow for simple contact detection and a single point of contact, they are not commonly found in the real world. As such, it's important to model other shapes, a capability that tools like Ansys Rocky provide.

Real particle shapes, such as polyhedrals, vary in their packing density, the linear and rotational modes of transport, dilating during shear and interlocking, and the strength of the materials. However, modeling real particle shapes can increase computational demands due to contact detection and overlap requirements.

The Role of GPU Processing and Coarse-Grain Modeling in DEM Simulation

GPU processing is a vital aspect of DEM simulation. Given that DEM tracks every particle at every time step, GPU processing can significantly speed up this process without sacrificing accuracy.

For cases with an overwhelmingly large number of particles, coarse-grain modeling might be employed. This approach reduces the total number of particles by using larger particles to represent a group of smaller ones, increasing computational efficiency.

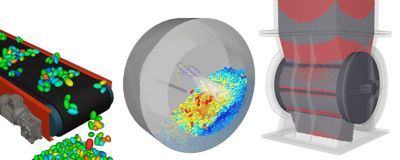

Advanced DEM Techniques: Coupling with CFD and SPH

To account for fluid forces and flow on particles, Computational Fluid Dynamics (CFD) can be effectively coupled with DEM. This method can be used with mesh-based approaches and any particle shape.

A technique increasingly used in hydrodynamics is the coupling of Smoothed Particle Hydrodynamics (SPH) with DEM. This approach excels in capturing complex free-surface flows with no diffusion errors, and is especially suitable when splashing or surface fragmentation is involved. The SPH-DEM method uses a Lagrangian meshless approach to capture flow dynamics by discretizing them into a set of fluid elements. Particles are then interpolated using a kernel function to compute smooth fields for local variables.

Applications of Discrete Element Method: Ansys Rocky

Ansys Rocky provides a unique platform for engineers across the spectrum of bulk material handling industries to computationally analyze their process by mapping the dynamic interplay of process, material, and geometric variables.

In order to achieve increased insight, Rocky allows for a number of advanced physical models, including:

- Multiphysics Models: Rocky is fully integrated with Ansys and allows state-of-the-art coupling with Computational Fluid Dynamics (CFD), Finite Element Method (FEM) and Lattice Boltzmann (LBM) packages to accurately simulate multiphase multicomponent flows.

- Complex particle shapes: Custom 3D and 2D particles to achieve realistic representation of particles, including high aspect ratio fibers; which can be made rigid or flexible.

- Complex motion: Complicated motion can be easily specified. Free body motion with 6 degrees of freedom can be specified can also be specified within Rocky, so external MultiBody Dynamics (MBD) software is not required.

- Breakage Model: Well established models for particle breakage, like ABT10 and Tavares models are included.