On September 5, 2016 an Atlas V rocketed from Cape Canaveral carrying the OSIRIS-REx spacecraft on a mission to discover the origin of our solar system by exploring the asteroid Bennu. Bennu may help us find answers to the questions central to the human experience: Where did we come from? What is our destiny?

The specific mission had the following objectives:

- Return and analyze a sample of Bennu’s surface

- Map the asteroid

- Document the sample site

- Measure the orbit deviation caused by non-gravitational forces (the Yarkovsky effect)

- Compare observations at the asteroid to ground-based observations

In October 2020, OSIRIS-REx conducted a “touch-and-go” maneuver to collect at least 60 grams, a far larger sample size than any other previous sample retrieval mission. On May 10, 2021, OSIRIS-REx fired its thrusters and heads on a 2.5-year course back to Earth.

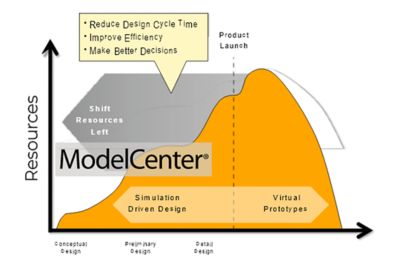

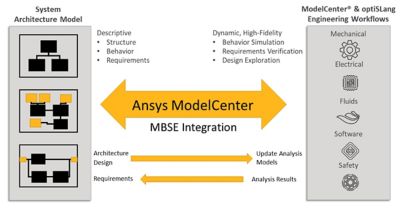

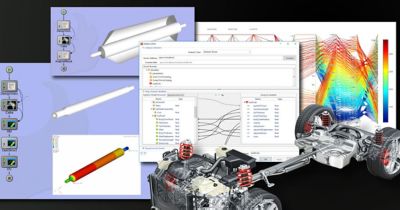

The OSIRIS-REx mission was complex and daunting. Preparing for it required months of testing, modeling, and analyzing each step. This case study explores how Lockheed Martin planned for the mission using ModelCenter® and ModelCenter MBSE to enable Model-Based Systems Engineering (MBSE) for the success of the mission.