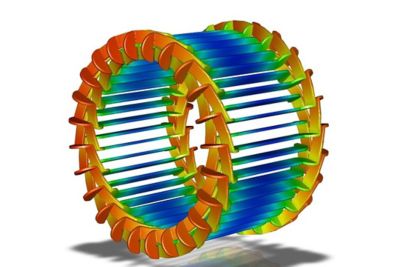

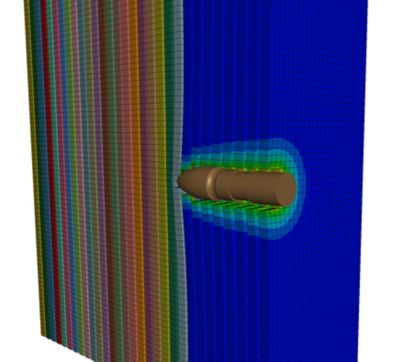

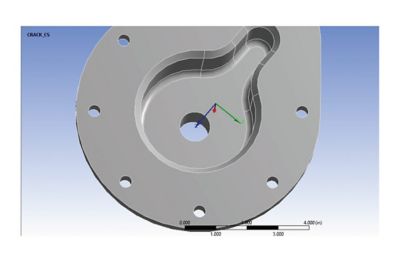

Symmetry in Ansys Mechanical enables users to only model a portion of the structure they are simulating to achieve faster simulation and post-processing results. Users can implement Symmetry if the geometry, material orientation, loading, and expected response all exhibit symmetry about the same planes.

To use Symmetry in Ansys Mechanical, you can either select the Model folder under your current project, navigate to the Model tab, and select Symmetry, or right-click on the Model folder and choose Insert then Symmetry. Both options above will insert a symmetry folder object where different types of Symmetry can be added.

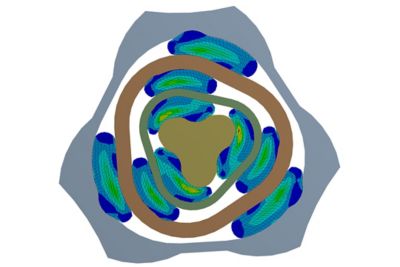

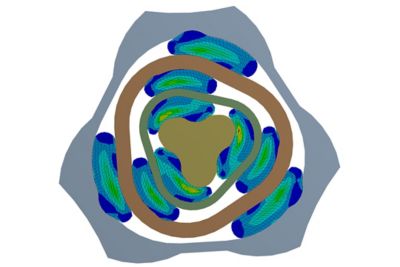

Based on analysis type and symmetry needs, the following Symmetry objects can be inserted: symmetry region, linear periodic, periodic region, cyclic region, and pre-mesh cyclic region.