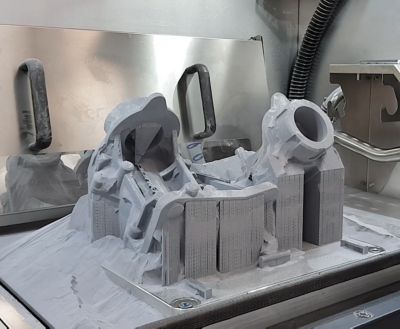

Additive manufacturing (AM), or 3D printing, is a group of advanced manufacturing processes that produce three-dimensional models from computer-aided designed models by adding material layer by layer. It can be a cost-effective way of making parts, especially when using the design freedoms the manufacturing process enables, such as topological complexity and the ability to print assemblies in one step.

AM applies in many industries, including aerospace and defense, automotive, consumer products, industrial products, medical devices, and machine tools. These are high-value parts that require careful design and manufacturing.

Ansys Additive Suite is a powerful collection of tools dedicated to additive manufacturing simulation. It simulates layer-by-layer deposition of materials undergoing Laser Powder Bed Fusion, Directed Energy Deposition & Sintering processes to predict the macro-level temperature-induced distortions and stresses in parts to prevent build failures.

It also determines optimum machine and material input parameters by simulating single bead parametric, parametric porosity, thermal history, and microstructure simulation.

What You Will Learn

- Learn Metal additive manufacturing applications

- Discover defects and build issues in metal AM

- How simulation supports AM product development

Who Should Attend

- Proprietors/directors/senior executives

- R&D engineers / heads / managers

- Design engineers / heads / managers

- Product development engineers / heads / managers

Speaker

Kumar Satyam