-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

THEMENDETAILS

Was ist computergestützte Materialwissenschaft?

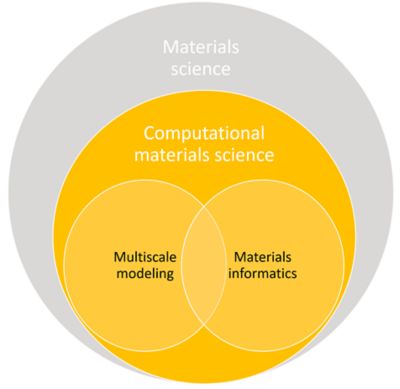

Die computergestützte Materialwissenschaft ist ein interdisziplinäres Gebiet, das eine höhere Effizienz bei Materialforschung, Materialdesign, Versagenseinordnung und Materialmodellierung sowohl in der Grundlagenforschung als auch in der Konstruktion von Produkten ermöglicht. Computergestützte Materialwissenschaft besteht aus einer Reihe von Methoden, mit denen Ingenieur*innen das Materialverhalten und die Eigenschaften von Materialien wie mechanische, thermische und elektromagnetische Eigenschaften untersuchen können.

Multiskalenmodellierung und Materialinformatik sind einander überlagernde und ergänzende Ansätze der computergestützten Materialwissenschaft, die physikbasierte und datengesteuerte Methoden kombinieren, um Materialverhalten zu verstehen, vorherzusagen und zu optimieren.

Neben der Fähigkeit, das Neumaterialdesign zu verstehen, hat die computergestützte Materialwissenschaft den Wissenstransfer durch interdisziplinäre Forschung ermöglicht. Fortschritte in der computergestützten Materialwissenschaft ermöglichen es nun mehr Industriebranchen, effizientere Materialsysteme und leistungsfähigere Produkte zu entwickeln, ohne dass mehrmals neue Prototypen erstellt werden müssen.

Trends bei der computergestützten Materialwissenschaft

Computergestützte Methoden werden in vielen Bereichen von Chemie und Materialforschung und -entwicklung eingesetzt, einschließlich moderner Werkstoffe, Verbundwerkstoffe (Keramik-, Kohlenstoff- und Polymerverbundwerkstoffe), und anderer Festkörpermaterialien. Die computergestützte Materialwissenschaft erstreckt sich auch auf viele technologische Anwendungen, darunter Energieerzeugung und Halbleiter.

Heute entwickelt sich die computergestützte Materialwissenschaft mit steigender Computerleistung und leistungsfähigerer Simulationssoftware kontinuierlich weiter.

Einer der bekanntesten Trends der letzten Jahre (der jetzt zu einer zusätzlichen Funktion geworden ist) ist die Verbindung zur Prozessmodellierung und wie sich der Fertigungsprozess auf die Eigenschaften eines Materials auswirkt. Mit immer stärker verbreitetem Einsatz der digitalen Fertigung bietet computergestützte Materialwissenschaft mehr Möglichkeiten, diese Prozesse zu verstehen und zu verbessern.

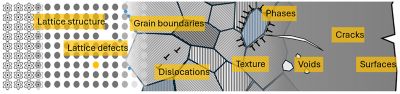

Ein weiterer Bereich, der in den letzten Jahren stark weiterentwickelt und genutzt wurde, ist die Multiskalenmodellierung, bei der rechnerische und ingenieurswissenschaftliche Techniken kombiniert werden, um Materialeigenschaften und Materialverhalten vorherzusagen und über mehrere Längenmaßstäbe, von der atomaren bis zur makroskopischen Ebene, zu optimieren. Dies wird bei der Entwicklung von Materialien zu einem beliebten Simulationsansatz. Er wird mit experimentellen Charakterisierungstechniken wie Transmissionselektronenmikroskopie (TEM) und Rasterelektronenmikroskopie (REM) kombiniert, um das Materialdesign vom Nanobereich ausgehend voranzubringen.

Materialien sind komplexe Systeme, deren Strukturen und Defekte über mehrere Längenmaßstäbe hinweg makroskopische Eigenschaften hervorbringen. Eine genaue Beschreibung erfordert oft Ansätze mit Multiskalenmodellierung. Es werden Beispiele für die vielen Strukturfehler gezeigt, die in einem Material zu finden sind.

Auf der Software-Seite ist wie in vielen anderen Bereichen heutzutage einer der größten aktuellen Trends die künstliche Intelligenz (KI). Verschiedene KI-Algorithmen können verwendet werden, um eine bessere Vorhersage und Optimierung von Materialeigenschaften und -prozessen zu ermöglichen, wenn sie mit den relevanten simulations- (und experimentellen) Daten versorgt werden. Dieses Tool beginnt in der computergestützten Materialwissenschaft und der Materialinformatik zu reifen, wo Algorithmen für maschinelles Lernen verwendet werden, um Materialeigenschaften vorherzusagen und die Effizienz der Materialentwicklung zu verbessern.

Computergestützte Modellierung auf atomarem Maßstab

Computergestützte Materialwissenschaft kann verwendet werden, um Struktur und Eigenschaften von Materialien in kleinen Längenmaßstäben zu verstehen, einschließlich auf atomarer und Nanoebene.

Neben der Modellierung des Materials selbst kann computergestütztes Hochdurchsatz-Screening die bekannten Eigenschaften noch herzustellender Materialien auf Grundlage ihrer Zusammensetzung und Kristallstruktur aus großen Datenbanken entnehmen, um das Material/die Materialstruktur mit idealen Eigenschaften für eine bestimmte Anwendung zu identifizieren. Da ein potenziell interessantes Material oft mehrere gesuchte Eigenschaften aufweist, konzentriert sich dieser Ansatz auf jede Eigenschaft einzeln, wodurch die Anzahl potenziell geeigneter Materialien im Laufe der Zeit verringert wird, wenn mehrere Eigenschaften untersucht wurden. Das spart Zeit und Energie, da keine Experimente nach dem Prinzip von Versuch und Irrtum durchgeführt werden müssen, um das passendste Material zu finden, und kann die Materialentwicklung beschleunigen. Diese Simulationen sind jedoch rechenintensiv und benötigen viel Zeit oder einen Computer mit viel Rechenleistung (oder beides).

Viele Methoden zur computergestützten Modellierung simulieren auf atomarer Ebene, und viele Variationen von Kernmethoden wurden für bestimmte Materialien und Anwendungen angepasst. Von allen Ansätzen sind Simulationen auf Grundlage von Dichtefunktionaltheorie (DFT), der Molekulardynamik (MD) und Monte-Carlo-Simulationen die gängigsten:

- Dichtefunktionaltheorie (DFT): Die DFT ist ein quantenmechanisches Modell, das das Verhalten von Elektronen in einem Material auf Grundlage seiner Dichte simuliert. Sie ist die am häufigsten verwendete Elektronenstrukturmethode zur Ableitung chemischer und energetischer Eigenschaften – die Vorhersage der Grundzustandseigenschaften (niedrigster Energiezustand eines Atoms) und der mechanischen Eigenschaften eines Materials.

- Molekulardynamik (MD): Die MD ist ein physikbasiertes Modell, das vorhersagt, wie sich jedes Atom in einer Simulation verhalten und mit anderen Atomen interagieren wird. Außerdem gibt sie Einblicke in die physische Bewegung von Atomen im Zeitverlauf. Die Positionen und Spannungen von Atomen können verwendet werden, um Materialeigenschaften vorherzusagen, und das Potenzial des maschinellen Lernens wird in MD-Simulationen integriert, um deren Genauigkeit zu verbessern und die Rechenkosten für Simulationen zu senken.

- Monte-Carlo: Monte-Carlo-Simulationen sind Berechnungsalgorithmen, die die Wahrscheinlichkeit eines Ergebnisses durch wiederholte Stichproben vorhersagen. Sie sind ein Hilfsmittel, das auf der Grundlage von Wahrscheinlichkeit die Partikelinteraktionen und komplexe Systeme simuliert.

Computergestützte Modellierung in größeren Maßstäben

Viele Rechenwerkzeuge werden auch verwendet, um Materialeigenschaften in viel größeren Maßstäben vorherzusagen – über die vielen Schichten eines Materials hinweg und nicht nur auf atomarer Ebene. Diese Ansätze mit Multiskalenmodellierung untersuchen die Makroeigenschaften des Materials (mechanisch, elektromagnetisch usw.), die Mikrostruktur und das Verhalten des Materials unter extremen Bedingungen (insbesondere bei anspruchsvollen Anwendungen).

Modellierungsmethoden in größeren Maßstäben fallen unter die Modellierung auf Kontinuumsebene und nehmen die auf den kleineren molekularen Maßstäben gewonnenen Informationen auf, um eine Verbindung mit dem größeren Materialsystem herzustellen. Dieser sequenzielle Ansatz ermöglicht eine präzisere, aber rechenintensive Modellierung auf atomarer Ebene, gefolgt von einer weniger rechenintensiven Modellierung im Mikromaßstab, sobald die Grundlagen vorliegen.

Während viele Rechenwerkzeuge für die Modellierung von vollständigen Materialsystemen verfügbar sind, sind einige gängige Hilfsmittel die Finite-Elemente-Methode (FEM), die Phasenfeldmethode und CALPHAD (Computer Coupling of Phase Diagrams and Thermochemistry, Computerkopplung von Phasendiagrammen und Thermochemie).

- Finite-Elemente-Methode (FEM): FEM ist eine numerische Simulation, bei der das komplexe Materialsystem mithilfe von Differentialgleichungen in ein Netz kleinerer Elemente aufgespalten wird, in dem jedes „Element“ einzeln untersucht werden kann. Zu verstehen, wie sich jedes Element verhält, ermöglicht es Ingenieur*innen zu verstehen, wie sich das Gesamtmaterial unter bestimmten Bedingungen verhält. Die FEM wird zur Durchführung von Strukturanalysen eines Materials sowie zur Untersuchung von Massentransport, Fluidströmung und elektromagnetischen Eigenschaften von Materialien verwendet. Die Ergebnisse einer Untersuchung mit FEM können durch eine Finite-Elemente-Analyse (FEA) interpretiert werden.

- Phasenfeldsimulationen: Phasenfeldmodelle sind mathematische Modelle, die Probleme an Materialschnittstellen lösen. Sie werden häufig verwendet, um Erstarrung und Grenzflächendynamik von Materialien zu modellieren, und können verwendet werden, um mechanische Eigenschaften wie Bruchmechanik und Sprödigkeit zu untersuchen. Sie können auch verwendet werden, um mehrphasige Modelle zu erstellen, die die Mikrostruktur eines Materials anhand bestimmter Parameter untersuchen, wie z. B. Kristallorientierung oder einer bestimmten Phase, und können die Eigenschaften von Materialien mit mehreren thermodynamischen Phasen untersuchen.

- CALPHAD: Dieses Modell erstellt Phasendiagramme zur Vorhersage der Phasenstabilität eines Materials bei unterschiedlichen Temperaturen und chemischen Zusammensetzungen. Die Modelle verwenden die thermodynamischen Eigenschaften jeder Phase in einem Material, um die Simulation durchzuführen, und werden häufig verwendet, um besser zu verstehen, wie sich ein Material unter verschiedenen Bedingungen verhält.

Chancen und Herausforderungen der computergestützten Materialwissenschaft

Wie bei jeder Simulation oder Berechnungsmethode gibt es Vor- und Nachteile bei der Verwendung eines Ansatzes auf Grundlage computergestützter Materialwissenschaft. Die Vor- und Nachteile können zudem je nach gewählten Hilfsmitteln unterschiedlich sein, da der richtige Simulationsansatz für ein Material nicht immer auch für ein anderes Material geeignet ist. Trotz der verschiedenen Rechenwerkzeuge, die verwendet werden können, gibt es allgemeine Vor- und Nachteile.

Möglichkeiten der computergestützten Materialwissenschaft

- Sie kann den Bedarf an umfangreicher experimenteller Entwicklung – sowohl Materialsynthese als auch -prüfung – in den frühen Phasen des Produktzyklus senken, indem sie Ansätze nach dem Prinzip von Versuch und Irrtum durch gezielte Simulationen ersetzt.

- Sie kann genutzt werden, um hochspezifische Eigenschaften, Prozesse, grundlegende Mechanismen, Materialumgebungen und Anwendungsszenarien zu untersuchen, die durch Experimente schwer möglich sind.

- Sie trägt dazu bei, die Kluft zwischen der Grundlagen-Materialwissenschaft und anderen Branchen und Anwendungsbereichen zu schließen.

- Sie ermöglicht es vielen Branchen, Materialien besser zu verstehen.

- Sie hilft Endnutzenden, über den Tellerrand zu schauen und Materialien als Konstruktionsparameter zu betrachten, was dazu führt, dass komplexere Materialien entwickelt werden.

Grenzen der computergestützten Materialwissenschaft

- Die gewonnenen Informationen über die Struktur von Materialien und ihre Eigenschaftsbeziehungen können manchmal zu allgemein sein, wohingegen die meisten Eigenschaften und Materialparameter in Experimenten häufig auf spezifische Werte quantifizierbar sind.

- Aufgrund der Komplexität einiger Mechanismen müssen Experimente durchgeführt werden, um das Materialverhalten richtig zu verstehen. Phänomene wie Versagen und Schäden lassen sich durch Berechnung allein nur schwer erfassen.

- Simulationen können durch die verfügbare Rechenleistung eingeschränkt werden, was zu einer hohen Simulationsdauer führt.

Herausforderungen der computergestützten Materialwissenschaft

- Die Rendite ist unklar, da es schwierig ist, eine computerwissenschaftliche Methodik für einen bestimmten Fall zu entwickeln.

- Sie ist ein teurer, zeitaufwändiger Prozess, der nur dann von Vorteil ist, wenn die Methodik wiederverwendet wird.

- Häufig benötigt sie spezifisches interdisziplinäres Fachwissen, um die Vorteile der Computermodelle in vollem Umfang nutzen zu können.

Könnte KI die computergestützte Materialwissenschaft verbessern?

Wie bereits erwähnt, wird der Einsatz von KI-Algorithmen in der computergestützten Materialwissenschaft immer häufiger. Aber wie genau hilft KI Ingenieur*innen im Bereich Werkstofftechnik und Maschinenbau?

KI findet auf atomarer bis mikroskopischer Ebene mehr Verwendung und trägt dazu bei, die Vorhersagefunktionen von Simulationssoftware zu verbessern, damit genauere Materialeigenschaften identifiziert werden können. Maschinelles Lernen hat auch einen großen Einfluss auf MD-Simulationen, da eine ähnliche Genauigkeit wie bei DFT erreicht wird. (Die Genauigkeit von DFT ist in der Regel höher.) Andere KI-Anwendungen entstehen, z. B. automatisierte Charakterisierungsanalysen, selbststeuernde Labors, Prozessoptimierung und Multiskalenmodellierung.

Die rasanten Fortschritte bei kommerziellen KI-Technologien bedeuten, dass viele Optionen zur Verfügung stehen, und die heute verwendete KI verbessert den Zugang zu materialwissenschaftlichen Informationen. Der Einsatz von KI in der computergestützten Materialwissenschaft befindet sich noch in einer Übergangsphase, wobei eine umfassendere Integration über mehr Tools möglich ist, wenn eines von zwei Dingen eintritt:

- Es gibt technischen Bedarf, sie zu verwenden.

- Sie ist in mehr Bereichen des Materialdesigns für die Materialwissenschaft kostengünstiger einsetzbar.

So unterstützt Ansys Unternehmen, die computergestützte Materialwissenschaft einsetzen möchten

Neue Materialien werden von Natur aus komplexer, um erweiterte Funktionen und Eigenschaften zu erreichen, und es ist wichtiger denn je, alle verfügbaren Hilfsmittel während der verschiedenen Phasen des Materialdesigns möglichst großflächig zu nutzen.

Ansys, Teil von Synopsys, kann auf Makroebene helfen, und verschiedene Simulationstools für Materialwissenschaftler*innen können bei der mehrstufigen Simulation Ihrer Materialien helfen. Es ist zu beachten, dass es bei der Simulation von Struktur und Eigenschaften von Materialsystemen keinen einheitlichen Ansatz gibt. Je nach Material und Anwendung kann eine breite Kombination von Simulationstools eingesetzt werden, von den internen Tools, die bei Ansys verwendet werden, bis hin zu Python-basierten Ansätzen.

Im Folgenden finden Sie Beispiele für Tools von Ansys, die beim Materialdesign verwendet werden können:

- Struktursimulationssoftware für nichtlineare Dynamik Ansys LS-DYNA: Die Software LS-DYNA kann verwendet werden, um Multiskalensimulationen zu erstellen, die die Mikroebene mit der Makroebene kombinieren.

- Das Tool Ansys Materials Designer: Mit dem Tool Materials Designer können Sie Materialnetzwerke untersuchen und die Mikrostruktur betrachten. Das Tool bietet außerdem ein natives Add-on und ein benutzerfreundliches Frontend für Homogenisierungsstudien.

- Die Produktsammlung Ansys Granta für Materialinformationen, Werkstoffauswahl und Datenverwaltung: Sie können die Software Granta verwenden, um Materialdaten zu verwalten und verschiedene Modelle während des Konstruktionsprozesses zu unterstützen. KI-Plug-ins von Granta können auch zur Verbesserung der Datenverwaltung und -unterstützung verwendet werden.

- Simulationsprozess- und Datenverwaltungssoftware Ansys Minerva: Die Software Minerva stellt sichere Simulations- und Prozessdaten bereit, um sicherzustellen, dass alle Simulationen und Daten, die während des gesamten Materialdesignprozesses erstellt werden, rückverfolgbar sind.

- Software für strukturelle Finite-Elemente-Analyse (FEA) Ansys Mechanical: Mit der Software Mechanical können Kristallplastizität und MAPDL für Multiskalensimulationen verwendet werden, die die Mikroebene mit der Makroebene kombinieren. Beim Prüfen repräsentativer Volumenelemente (RVE) mit unterschiedlichen Phasen können periodische Grenzen durch Mehrpunktbeschränkungen (MPC) emuliert werden.

Ansys schneidet den Ansatz auf die Anforderungen Ihres Materialdesignprozesses zu und nutzt dabei das Fachwissen unserer Material- und Simulationsingenieur*innen. Wenn Sie herausfinden möchten, was die optimale Mischung aus Tools für Ihre Materialsysteme wäre, wenden Sie sich an unser Ingenieurteam, um eine maßgeschneiderte Simulationslösung zu erhalten.

Zugehörige Ressourcen

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.