-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

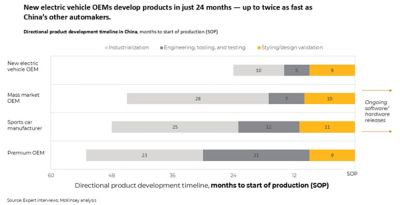

According to McKinsey & Co., China is the world’s largest, fastest-growing, most competitive automotive market. And that’s no accident. Chinese automakers focused on electric vehicles (EVs) are developing them in roughly 24 months, from concept to launch — twice the speed of legacy automakers, where lead times can reach upwards of 40 to 50 months. Similarly, Tesla’s lean manufacturing approach has helped it capture significant EV market share.

What does this mean for everyone else? Less time to differentiate with new technologies and first-to-market features.

There’s no question that legacy automakers are being pushed and pulled in many directions. They find themselves in the midst of significant disruption, scrambling to address recent technological and geopolitical shifts, as well as changing consumer priorities.

This is the first of two blogs that consider specific trends and challenges influencing the current automotive climate. It explores how simulation will enable carmakers to navigate a changing market to create new opportunities.

Stagnant Global Vehicle Volume

After decades of steady growth, the global automotive market is reaching a saturation point. Right now, the set number of vehicles produced annually is hovering at some 93 million units. There’s little room for new players as market share is closely tied to profit per vehicle, making it crucial for manufacturers to protect and grow their positions.

“Chinese OEMs are setting the bar, having become a formidable contender in the electric vehicle (EV) sector,” says Walt Hearn, senior vice president of Worldwide Sales and Customer Excellence at Ansys, part of Synopsys. “Some have managed to slash traditional development timelines, from concept to launch, by nearly 50%.”

This is also true of Tesla, which has a healthy 46% of EV market share in the U.S., as well as newer U.S. entrants like Rivian and Lucid.

In response, carmakers are finding creative ways to maintain their competitive edge. The partnership between GM and Hyundai is one such example. This collaboration on five co-developed vehicles for Central and South America taps into historically underserved markets to gain a competitive advantage against emerging players. Still others are reevaluating product portfolios to better respond to shifting customer preferences, such as increasing demands for affordability.

This trend extends to battery technology powering EVs of the future, such as vehicle software and sustainable manufacturing practices aimed at minimizing scrap costs on the gigafactory floor.

Honeywell Process Solutions helps organizations solve complex challenges in automation, process control, and quality management related to battery manufacturing. The company looks to simulation to support a data-driven, model-based approach to production, leading to higher yield, lower costs, and improved energy efficiency for battery manufacturers into various markets, including EVs, electronics, energy storage, and consumer goods.

Launch Delays and Changing Strategies

Complications due to increasing vehicle complexity and shifting market dynamics are causing significant launch delays, forcing automakers to regroup. Software-driven experiences, in particular, create more testing hurdles on the way to ensuring vehicles are reliable and will satisfy safety standards before they hit the market.

These delays can be costly, not only in terms of development dollars, but in the erosion of consumer trust. Other factors contributing to structural shifts within the industry include a geopolitical environment framed by tariffs and trade barriers; delayed technology rollouts including the slow transition to EVs; and slower transitions than planned to software-defined vehicle (SDV) and autonomous driving (AD) technologies.

Automotive engineers face multiple challenges to meet consumer demands.

In this environment, automakers are forced to quickly pivot. They’re scaling back EV production in favor of hybrids or reallocating production facilities to optimize costs. Such shifts, however, are neither simple nor inexpensive. In the end, they require extensive retooling and planning, making them both complicated and costly to execute.

Simulation plays a vital role, enabling automakers to validate new strategies, optimize production plans, and reduce the risks associated with making changes late in the development process via the strategies below.

- AI-based automation throughout the automotive value chain, driving major transformations in AV, manufacturing, and customer experience.

- Data-driven decision making through real-time data platforms like agentic AI (a class of AI systems that can autonomously make decisions with less human intervention), which could be used to help optimize efficiency, safety, and innovation in car production.

- Lean manufacturing through the systematic identification and elimination of waste within a given manufacturing system.

- Supply chain optimization with a focus on effective supply chain management with tier suppliers; inventory control to minimize production delays and increase operational efficiency; and streamlining logistics to deliver both components and finished products.

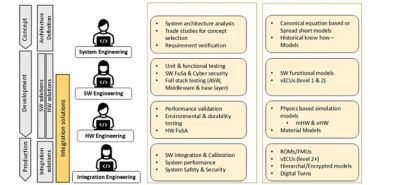

One modeling strategy that has quickly gained traction as a means of overcoming launch delays are virtual electronic control units (vECUs). These digital models enable automakers to validate new strategies, optimize production plans, and reduce the risks associated with making changes late in the development process.

They’re also a real game-changer for engineers in the optimization of modern vehicles.

Scalable Virtualization

Consider the SDV, a vehicle architecture whose functionality relies on tightly integrated software stacks running across dozens of interconnected ECUs. Software validation at this level of complexity typically depends on physical prototypes such as bench setups and HIL rigs. The work is cumbersome. It’s slow-going. And it’s costly.

When you can break things in a digital environment, everything changes. The use of vECUs enables rapid, iterative software stack development and testing before hardware exists. A vECU can emulate the behavior of all ECU components involved, giving engineers the freedom and flexibility to execute the same code intended for the real ECU, debug high-level and low-level functions, validate integration earlier, and run massive test campaigns in parallel.

Modern vehicles require collaboration among many engineering disciplines.

Of course, ECU virtualization alone isn’t enough. To validate real-world behavior, virtual ECUs must be connected to accurate system, plant, sensor, and environment simulations. By coupling high-fidelity simulation platforms with virtual ECUs, engineering teams can recreate the complete operational context across a range of functions. These include dynamics, sensors, actuators, traffic, weather, and specific edge cases that are dangerous if not impossible to test in real life.

This combination unlocks major advantages during development:

- Earlier integration of complex systems (fewer surprises)

- High scalability (run of hundreds of scenarios in parallel)

- Increased reliability of the software stack (test of edge case scenarios)

- Faster innovation cycles (no physical setup, development cycles shrink dramatically)

“Simulation and vECUs together create a continuous, hardware-independent development loop, which is exactly what is needed to master the complexity of SDVs, zonal architectures, and autonomous driving software,” says Pierre Vincent, director of application engineering at Ansys.

“Physics-based simulation of hardware like actuators and sensors, in combination with AI, can take hardware virtualization to a whole new level,” says Gopinath Penamalli, automotive technical account manager at Ansys. “Integrating them with vECU at multiple levels to virtualize the full system (both HW and SW) will lead to continuous validation through virtualization, a shift left strategy which is key to realizing SDV.”

As we “shift left” with SDV and virtualization strategies in automotive design, capturing design intent for safe and secure ECU software is a key objective. Design intent is captured through requirements to meet compliance for standards like ISO26262, ISO21448, PAS8800, and ISO21434. Validating them through simulation with digital engineering can help to reduce costs and accelerate design cycles.

More Trends on the Way

If you enjoyed this blog, you’ll want to check out part two of our automotive trends series. We’ll be drilling down on trends related to increasing vehicle complexity and the reprioritization of autonomy investments, as well as simulation’s role in helping carmakers navigate them. For a deeper discussion on vECUs, be sure to catch Digital Engineering Technology for Software-Defined Vehicles.

Just for you. We have some additional resources you may enjoy.

“Physics-based simulation of hardware like actuators and sensors, in combination with AI, can take hardware virtualization to a whole new level.”

— Gopinath Penamalli, automotive technical account manager, Ansys, part of Synopsys

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.