-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

Highlights from a special CES session, including insights from Judy Curran, senior chief technologist at Synopsys.

To kick off the new year, the Synopsys booth at CES featured cars from some of the biggest names in motorsport and an immersive video experience showcasing simulation. Elsewhere in West Hall, Andrew Melnizek, marketing and brand development executive, media and entertainment at The Verge, moderated a special panel, “Accelerating Product Development With Virtual Materials and Simulation.”

The 3M initiative brought together industry thought leaders from 3M, Audi AG, and Synopsys to discuss how the convergence of automotive, materials science, and software engineering is reshaping vehicle development — not just what is built but how it is built. Read on for a quick recap of the biggest insights coming out of this panel.

Designing at Speed and Scale

What do you get when you combine automotive design with the computational power of simulation and materials science? Faster, more accurate decision-making in the execution of vehicle materials early in the development process. With product development cycles moving at an unprecedented pace, this is indeed good news for manufacturers looking to material optimization for weight reduction, improved durability, and sustainability.

Virtual materials are intrinsically tied to a process that relies on the use of digital models and simulation. They are used to represent physical materials during analysis in a simulation environment. Taken in the context of an entire vehicle design, this approach to material analysis helps minimize material inefficiencies to address design flows or material inconsistencies early.

“Expectations are getting higher, and the cost of getting it wrong is bigger than ever,” says Melnizek. “It requires deeper collaboration across materials, software, and engineering — and a much heavier reliance on virtual development and simulation. … Virtual materials and simulation are helping teams move faster, make better decisions earlier, and reduce the risk across product life cycles.”

Reliance on simulations for material and process optimization enables engineering teams to make rapid design adjustments in real time. Further, these technologies are vital for maintaining material quality throughout the product life cycle — an enduring consumer expectation.

“Accelerating Product Development With Virtual Materials and Simulation” panel participants, from left to right: Andrew Melnizek, marketing and brand development executive, media and entertainment at The Verge; Drita Roggenbuck, president, transportation and energy vertical at 3M; Judy Curran, senior chief technologist at Synopsys; and Poorab Sarmah, SVP, infotainment and interior interaction at Audi AG

Cultivating a Culture of Innovation and Collaboration

At the core of 3M’s ethos lies a deeply ingrained focus on fostering innovation and collaboration. This approach is encouraged in its use of artificial intelligence (AI), virtual workbenches, and other simulation capabilities among teams to better understand the company’s extensive portfolio of over 44,000 technologies, including its advanced automotive materials.

Still other collaborations extend beyond the internal workings of 3M.

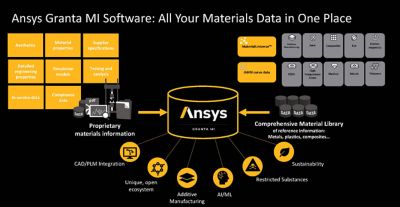

“We are working with Ansys and Synopsys to upload our material data into their systems (and) provide those simulation models for our tiers and our OEMs to bring new innovations to market,” says Drita Roggenbuck, president, transportation and energy vertical at 3M.

This approach enables 3M to quickly iterate on designs and deliver solutions tailored to the needs of its automotive customers. And it ensures that 3M’s contributions to component building are ultimately effective during product performance.

“I think with all of the different interactions and the innovative minds that we have, really working through simulation with Synopsys, looking at Audi and what Audi’s doing with the future of their vehicles, it’s really bringing that back into 3M to be able to execute and really work as fast with our customers,” says Roggenbuck.

The Synopsys booth debuted in the West Hall at CES.

The BMW M Hybrid V8 in the Synopsys CES booth

Speeding Through Analysis With AI and Simulation

Unprecedented speed is the primary driver for the use of AI and simulation in automotive design. Recent advancements in computational power enable faster, more detailed simulations, resulting in accelerated analysis. And the value of working faster opens doors for design exploration at a previously unimaginable pace.

“The level of complexity that we deal with nowadays, I know I’ve been in auto for about 20 years, and it’s amazing to see the speed, the innovation, and the technology that’s coming from automotive, and that’s affecting every one of our lives,” says Roggenbuck. “And it’s really interesting to see how you can use AI to not only manage the level of complexity that’s coming your way but how (to) really understand that level of data, develop it in, and iterate quickly.”

A significant byproduct of AI and faster data processing is, of course, much faster analysis that leads to even faster decision-making. AI can be seamlessly integrated into an automotive development workflow to quickly solve a multitude of challenges simultaneously — whether you’re addressing aerodynamic efficiency or analyzing material characteristics.

For example, running machine learning models capturing common challenges in aerodynamics can be solved with just a few simulations. The real-time analysis of various design attributes, including materials in consideration of vehicle shapes and components, is realized via AI through faster, more detailed simulations early in the design process.

“When you think about the compute capability that’s now available with GPUs and CPUs, the ability to compute all of the requirements of the vehicle is much faster,” says Judy Curran, senior chief technologist at Synopsys. “AI has really helped speed up the development process.”

The GEN3 Evo Porsche 99X Electric in the Synopsys CES booth

A view of the Synopsys booth's interactive tunnel at CES. This experience showcased videos demonstrating the use of simulation in various automotive applications.

Integrating Feedback Loops for Continuous Improvement

If you want to enhance both design and functionality, employing feedback mechanisms at various stages of development is the way to go. For Audi, feedback loops are essential during design studies when designing a new product or updating the design of an existing one.

“The first study (we run) is typically virtual with simulation, and we expose either experts or end users to this and get feedback, which is qualitative feedback,” says Poorab Sarmah, SVP, infotainment and interior interaction at Audi. “There is also a phase (involving) prototypes and materials, where you get feedback on usability and design and likability, which plays an important role, and it influences the design quite early.”

Carmakers, including Audi, are also prioritizing post-production feedback, a crucial aspect of automotive development in an increasingly software-defined world focused on system issues and improvements.

“Where we are learning really fast is post-production feedback, both in terms of usability of the product but also how much of the product is even used in the field,” says Sarmah. “And that becomes possible now because we are talking about software-defined vehicles, meaning the functionality is cloud-connected in terms of both usability, as well as data that is collected from the usage of the vehicle. So that feedback is not only helping us fix issues, but we are also able to make contextual, very personalized updates to the end consumer.”

When Being Materialistic Is a Good Idea

In automotive circles, the growing complexity of vehicle systems is a significant pain point. In the quest for faster, more efficient, and precise product development cycles, 3M has seemingly found that sweet spot. Dynamic interaction among 3M, its partners, and its customers, along with the right digital tools, can accelerate innovation and ensure that ever-changing expectations for quality and performance are consistently met.

These considerations extend to the material selection process, an important factor in lightweighting, durability, sustainability, performance, and cost in modern vehicle applications.

“One of the ways that we partner with 3M is we have a (materials data management software), and they’re able to put the materials … the characteristics of those materials in this database,” says Curran. “So as Audi or other OEMs are designing components or systems, they might be looking for a specific material that is a certain strength (or) might have a certain loss. And then they can use this database to see, OK, what material would that be? And then they can simulate that material and see, OK, will that work for us?”

Of course, material selection is just one part (albeit an important one) of vehicle design. In the end, an increasing reliance on virtual tools — not only consideration of materials but how they affect a design in its entirety — will continue to be crucial in meeting shorter development cycles and more efficient processes.

Make sure to check out the Ansys Granta Materials Data for Simulation properties database for more information about how Ansys, part of Synopsys, can support your materials selection process.

Just for you. We have some additional resources you may enjoy.

“Virtual materials and simulation are helping teams move faster, make better decisions earlier, and reduce the risk across product life cycles.”

— Andrew Melnizek, marketing and brand development executive, media and entertainment, The Verge

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.