-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

In the high-stakes, fast-paced world of automotive manufacturing, the race to innovate and launch products quickly has never been more intense. Traditional product development — heavily reliant on time-consuming physical testing — is giving way to digital simulations that promise faster, more cost-effective results.

Simulation has been a staple in automotive design for decades, but its role has undergone a dramatic shift. In the early 2000s, simulations were primarily a feedback tool for designers that complemented physical tests. Analysts would run simulations, provide insights, and rely on physical prototypes to validate designs. However, the rising cost of physical testing and delays in product launches, coupled with advancements in computing power, has flipped this relationship.

The move to digital testing has placed simulation teams at the heart of the design process, and simulation has become the driving force behind design decisions and product validation. However, this increased reliance on simulation has produced new challenges, such as how to manage massive amounts of data and ensure collaboration between teams spread across the globe, all while rapidly delivering actionable insights. With reduced reliance on physical testing, organizations now place greater emphasis on simulation result reviews and formal signoffs to ensure confidence in design decisions.

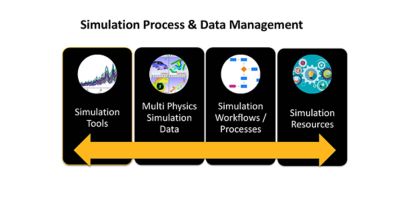

Designed specifically for the world of virtual testing and analysis, simulation process and data management (SPDM) empowers the elevated role of simulation in the automotive design process. A specialized system of tools and practices, SPDM streamlines the life cycle management of complex simulation data, simulation tools, simulation workflows, and processes.

VCOLLAB, a pioneer in transforming simulation results into engineering intelligence, is revolutionizing the way automotive products are designed, validated, and launched by integrating its Rapid Results Review™ (RRR) process with SPDM systems. RRR automates the consolidation of insights from multiple simulation tools into compact, SPDM-ready 3D computer-aided engineering (CAE) reports. Paired with SPDM, this enables secure, traceable access to simulation knowledge and facilitates faster, more visual collaboration between design and analysis teams, accelerating decision-making across the product development life cycle.

The Evolution of Simulation: From Support Tool to Industry Driver

In 2018, when General Motors CEO Mary Barra unveiled GM’s plan to transition to 100% digital testing by 2025 and phase out physical testing entirely, the announcement effectively ratified both a technological and a cultural change for the industry. This historic move reflects the enormous growth in confidence in simulation’s ability to accurately predict real-world performance. Also, with a transition to fully digital testing, the industry-wide goal of cutting product launch cycles down from four years to as little as two is suddenly feasible.

The only downside? All this digital testing creates a data deluge.

Twenty years ago, automotive companies were using upwards of 200 different CAE solvers, with each producing data in unique formats. This resulted in what one analysis team described as a “nightmare” of 400 input and output formats. These large, complex files were difficult to store, share, and analyze, especially for teams on different continents. At the time, transferring a 100 GB file could take half a day, delaying critical design decisions.

While computing speeds and bandwidth have increased massively since then, the sheer amount of data required by the modern era of digital engineering has outpaced these improvements. The workload for simulation teams has skyrocketed. With physical testing scaling back, companies are running even more simulation studies to achieve the same confidence that physical prototypes used to provide. This has led to an exponential growth in demand for simulation results. Analysts now face increased pressure to deliver their insights to product designers and project managers with quick turnarounds while ensuring critical issues like potential failure hotspots are not missed.

Compounding these challenges is the inefficiency of standard post-processing methods.

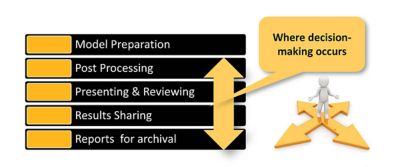

Analysts commonly spend roughly 30% of their time on manual tasks like opening large results files, clicking through data to identify key insights, and creating static PowerPoint slides. These reports often lack the depth required for thorough analysis, forcing teams to postpone meetings or rerun analyses to answer follow-up questions. In an industry in which speed and accuracy are essential, such holdups create significant bottlenecks.

The Power of SPDM: A Centralized Solution

SPDM addresses these challenges by providing a centralized platform to manage simulation tools, data, and processes. Essentially, SPDM is a single source of truth that consolidates the complexity of multisolver, multiphysics simulation environments. Through tools like Ansys Minerva software, SPDM offers several key benefits:

Centralized Data Management: SPDM creates a unified repository for all simulation data, facilitating easy storage, search, access, and retrieval of information through specified queries that produce relevant metadata and context. This forms the foundational Knowledge Database for the entire simulation ecosystem.

Process Automation: Routine tasks like job submissions or data extraction are automated, reducing manual effort and minimizing errors.

Global Collaboration: SPDM enables seamless collaboration across geographically dispersed teams, ensuring designers, analysts, and executives have access to consistent, accurate data.

Multiphysics Integration: SPDM handles data from diverse solvers — whether for structural analysis; computational fluid dynamics (CFD); or noise, vibration, and harshness (NVH) — to bring everything under one umbrella.

However, implementing SPDM comes with challenges of its own. Companies must decide what data to store and which processes to automate. Raw data from solvers contains valuable insights, but it is usually very large and often riddled with “noise,” or unwanted data from inputs like random sensor fluctuations that can obscure patterns, which makes it necessary for expert analysts to sift through it manually. Therefore, SPDM must balance long-term storage needs with the reality that only key insights are worth archiving.

VCOLLAB and Rapid Results Review Are Transforming Post-Processing, Reviewing, and Design Decision Support

While SPDM streamlines data management, the post-processing and review of simulation results can be another critical bottleneck. This is where the RRR solution shines. VCOLLAB developed RRR to reimagine how analysts process, review, and communicate results.

Unlike traditional methods that rely on tech nearing obsolescence, RRR introduces smart automation and interactive 3D digital slides, delivering insights faster and with greater depth.

Key features of RRR include:

Automated Data Extraction: RRR automatically extracts key insights and metadata from raw simulation files, reducing file sizes by up to 90% and eliminating the need for manual post-processing. Crucially, RRR transforms this raw native results data into a solver-independent, compact, and concise results file that can be easily stored, archived, visualized and shared in SPDM systems. By mining data for critical insights like failure hotspots, RRR ensures analysts don’t miss potential issues, reducing the risk of costly product recalls.

Interactive 3D Digital Slides and Knowledge Dissemination: Instead of static reports, RRR generates dynamic 3D slides that embed product performance information (PPI), such as stress values, displacement hotspots, or computational fluid dynamics (CFD) flow. These digital slides include labels, XY plots, and titles for context associated with the model, making the model itself the report and making the results immediately understandable, reviewable, and sharable for informed design decisions. RRR serves as the primary knowledge dissemination and review platform within the SPDM system for democratizing simulation knowledge to simulation consumers and other stakeholders in the enterprise with easy interfaces and graphical user interface (GUI) controls.

Analysts can interact with these slides to rotate models, adjust scale factors, or explore multiphysics data on a single model. This interactivity enables deeper analysis, as well as faster and more informed decision-making. The digital slides are accessible on any device, requiring no plugins or additional software installations. This enables stakeholders ranging from designers to executives to effortlessly review results through RRR 3D Dashboards within SPDM.

Smart Automation With Analyst Control: RRR automates 80% of the post-processing workflow but leaves 20% for analysts to apply their expertise. This “80/20 rule” ensures automation doesn’t produce “dumb” outputs like more traditional options, which can strip data of context and limit customization. Analysts can further post-process digital slides, annotate findings, and choose how to share results, whether as interactive slides, GIF animations, videos, or PowerPoint exports for specific audiences.

Seamless Integration With SPDM and PLM: RRR integrates tightly with SPDM systems, automating the handoff from simulation results to review-ready slides. It also connects with product life cycle management (PLM) systems, enabling a designer to access those insights. For instance, a computer-aided design (CAD) model transferred from PLM to SPDM is meshed, solved, and processed into digital slides by RRR. These slides can then be shared back to PLM by SPDM for designers to review, closing the gap between simulation results and design decisions.

Multiphysics and Multisolver Support: RRR handles data from any solver, making it ideal for complex multiphysics simulations. For example, an analyst can review a model with attributes from CFD and electromagnetic simulation in a single interface that offers specific failure criteria to aid in quick decision-making.

Benefits for the Automotive Industry

This combination of Minerva software and RRR delivers transformative benefits for automotive companies:

Increased Efficiency: By automating data management and post-processing, SPDM and RRR free analysts from repetitive tasks, giving them back 30% or more of their time to focus on high-value simulations. VCOLLAB templates in RRR further accelerate report generation, helping decrease the overall time to launch a product.

Reduced Risk: RRR’s smart data mining ensures no failure hotspots are missed, mitigating the risk of product failures or recalls in a simulation-driven design process without physical testing.

Faster Time to Market: Streamlined processes and enhanced global collaboration capabilities enable companies that utilize these solutions to shorten development cycles, meet the industry’s demand for rapid product launches, and gain an edge over their competitors.

Enhanced In-House Collaboration and Comprehension: Interactive digital slides make simulation results accessible to non-analysts, including designers and executives, significantly enhancing their comprehension. This enables innovation by fostering better communication and faster decision-making across teams.

Cost Savings: RRR’s slides require no additional plugins and are accessible by any device, which reduces IT costs. Smaller file sizes also lower storage and high-performance computing (HPC) demands.

AI-Ready and AI-Driven Insights: RRR actively extracts and curates actionable insights in structured formats, making it a valuable entry point for AI-driven predictive modeling. This enables companies to leverage emerging AI technologies now, and as AI learns from this data, it can provide even deeper, more predictive insights that are then disseminated through RRR.

Going Forward: SPDM, RRR, and AI for Intelligent Engineering

As the automotive industry embraces digital transformation, SPDM and RRR are laying the groundwork for the sector’s future. Considering the growing role of AI in simulation, RRR significantly contributes by curating and preparing data for AI workflows. Through the extraction of insights from multisolver data, RRR can create the SPDM-managed Knowledge Database with curated, AI-optimized data assets that AI systems can draw from to predict performance, optimize designs and identify subtle anomalies. Currently, VCOLLAB is collaborating with Ansys on the creation of such an AI-optimized data repository within SPDM that can integrate with Ansys SimAI cloud-enabled generative AI software, enabling enhanced post-processing, AI-driven insights, and direct support for reviews and design decisions.

The automotive industry is at a turning point, with digital testing becoming the cornerstone of product development. SPDM and RRR from VCOLLAB are revolutionizing how companies manage and leverage simulation data. By addressing the challenges of data complexity, inefficient post-processing and results review processes, and collaboration between global teams, this powerful combination unlocks unprecedented efficiency, reduces risk, and accelerates new product rollouts. This integrated approach transforms raw simulation outputs into actionable intelligence.

For companies striving to stay competitive in an increasingly digital world, SPDM and RRR are not just the latest upgrades — they’re necessities. These tools empower simulation teams to deliver rapid, actionable insights. They enable designers to make informed decisions, and, perhaps most importantly, they’re preparing manufacturers to fully harness AI for future innovation. As General Motors’ 2025 vision of 100% digital testing becomes the current reality, SPDM and RRR are paving the way for a smarter, faster, and more innovative automotive industry to produce more efficient and safer products for their customers.

Learn more about Minerva SPDM software and discover how it can help your business.

Just for you. We have some additional resources you may enjoy.

“For companies striving to stay competitive in an increasingly digital world, SPDM and RRR are not just the latest upgrades — they’re necessities.”

— Prasad Mandava, co-founder and CEO, VCOLLAB

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.