-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

Learn how simulation helps digital transformation challenges in industry by bridging skill gaps, enhancing data management, and streamlining system integration.

Despite the rise of Industry 4.0 and 5.0, industrial equipment and manufacturing industries, including construction and heavy machinery, haven’t fully embraced digital transformation.

A 2024 survey from the Manufacturing Leadership Council, a division of the National Association of Manufacturers (NAM), revealed that 70% of manufacturers still collect data manually. Another report from Deloitte Access Economics, commissioned by Autodesk, found that over 80% of construction companies could improve their data capabilities, including eliminating up to 11.5 hours a week that engineers spend looking for and analyzing data. The study also found that 62% of that data isn’t even used to make business decisions.

But poor data management isn’t the only challenge delaying digital evolution in industry. Studies show that skill gaps and attachment to legacy systems also create resistance.

How can organizations simplify integration, manage data overload, and still maintain efficient workflows and profitability? Simulation software from Ansys, part of Synopsys, provides easy-to-implement solutions through a comprehensive and open ecosystem of multiphysics simulation tools that address all areas of physics. The suite also includes specialized tools for technologies such as digital twins and artificial intelligence (AI). Additionally, Ansys Connect solutions support digital engineering further by linking simulation, data, and resources across an organization into a single digital thread. These solutions include simulation process and data management (SPDM), materials management, and process integration and design optimization (PIDO).

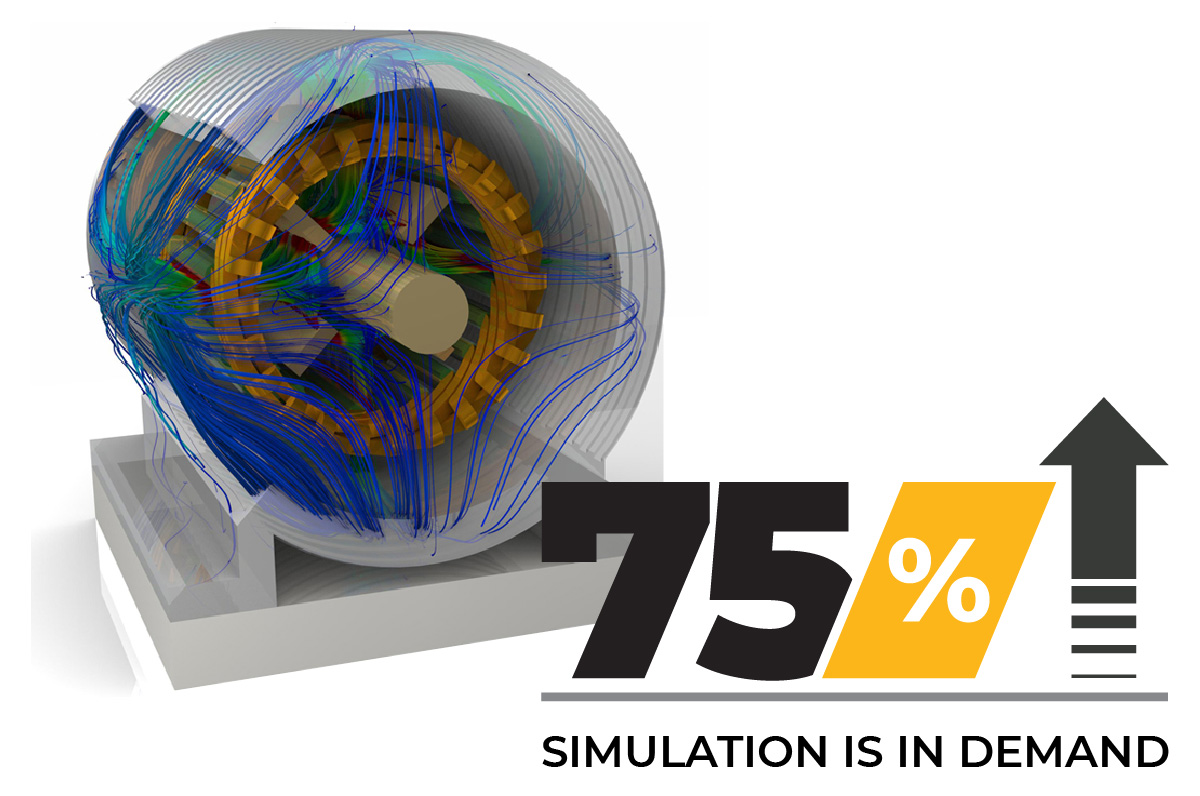

Analysts from Deloitte Research Center for Energy & Industrials studied job posting data for the past five years and found a 75% increase in demand for simulation and simulation software skills.

Let’s explore how simulation supports digital transformation in the industrial equipment and manufacturing industries, one challenge at a time.

Democratize Simulation, Shorten Skill Gaps

The 2024 Deloitte and The Manufacturing Institute Talent Study revealed that 1.9 million manufacturing jobs could remain unfilled by 2033 due to a skills gap, underscoring that skill requirements are evolving to include technical-manufacturing, digital, and soft skills. The report also emphasizes an applicant gap as the current workforce retires and recent graduates pursue other degrees or fields. Changing workforce expectations for younger generations also affect hiring and retention. To retain top employees, many organizations are investing in upskilling while, at the same time, looking at ways to increase automation and simulation democratization.

Deloitte researchers analyzed job posting data for the past five years and found a 75% increase in demand for simulation and simulation software skills.

An open ecosystem with application programming interfaces (APIs), automation, and algorithms, such as AI and machine learning (AI/ML), makes simulation more efficient for experts and accessible to nonexperts. There are unique democratization solutions to explore for different types of applications, users, and automation goals.

Ansys Discovery 3D product simulation software combines interactive geometry modeling and fast, high-fidelity multiphysics simulation into a single platform. Discovery software enables designers and even nonexperts to answer critical design questions early in product development. This easy, upfront approach to simulation saves time and effort with prototyping as you explore multiple design concepts quickly in real time.

The PyAnsys pythonic access tool for Ansys software provides a gateway to advanced engineering automation. Pythonic access is enabled across the entire Ansys platform to empower engineers to script and customize complex multi-tool, multiphysics simulation workflows and encapsulate and simplify them as apps for users at all levels.

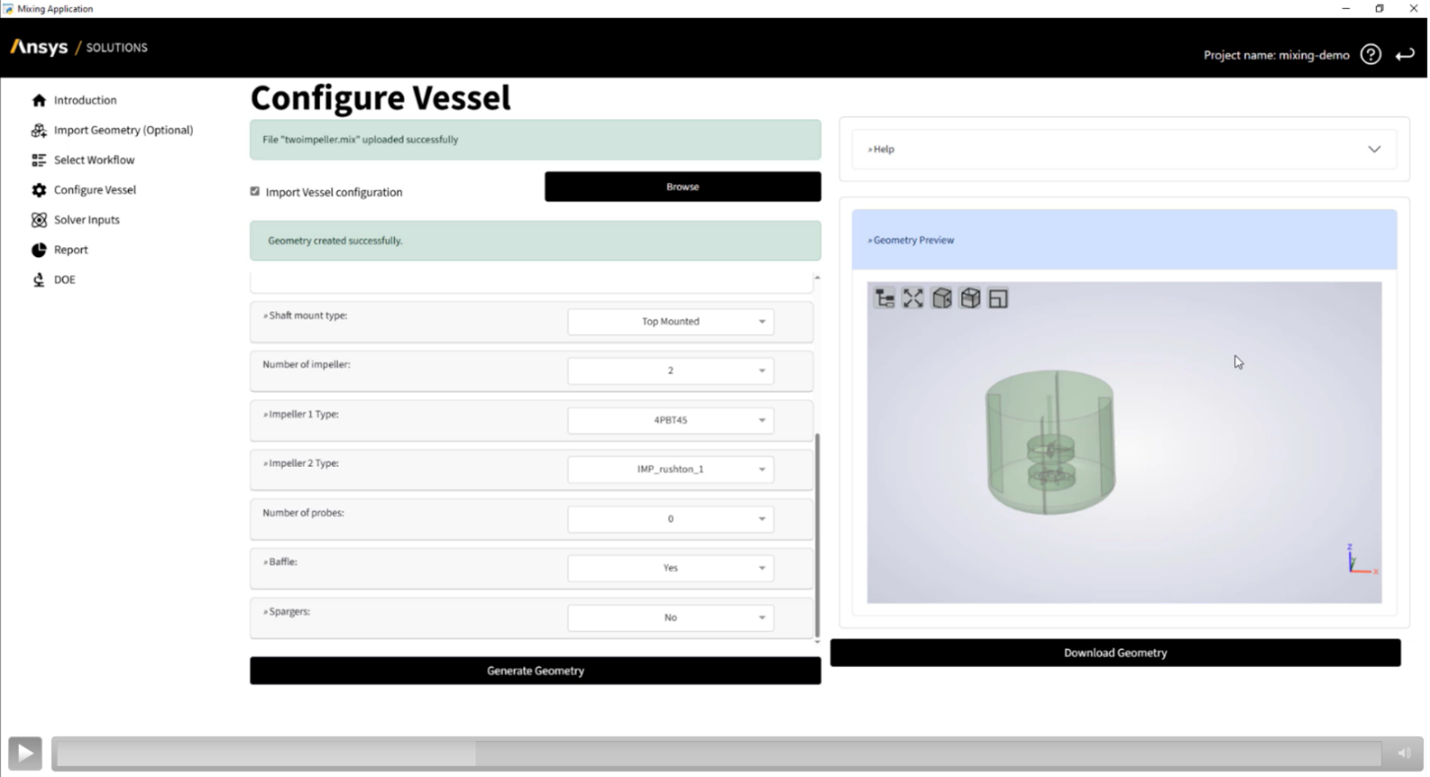

An application was created to democratize simulations of the mixing process using a combination of technologies in the PyAnsys ecosystem and the service automation framework (SAF).

Similarly, thanks to built-in AI algorithms, you can use Ansys optiSLang PIDO software without simulation, optimization, or AI expertise.

The simulation specialist on your team can create an optiSLang-based simulation workflow, capture repeatable processes, and publish them as apps to Ansys Minerva SPDM software or a dedicated service automation framework (SAF). Nonexperts can then use the app with minimal inputs to run simulations. This democratizes the power of advanced simulation, increasing usability, scalability, and efficiency.

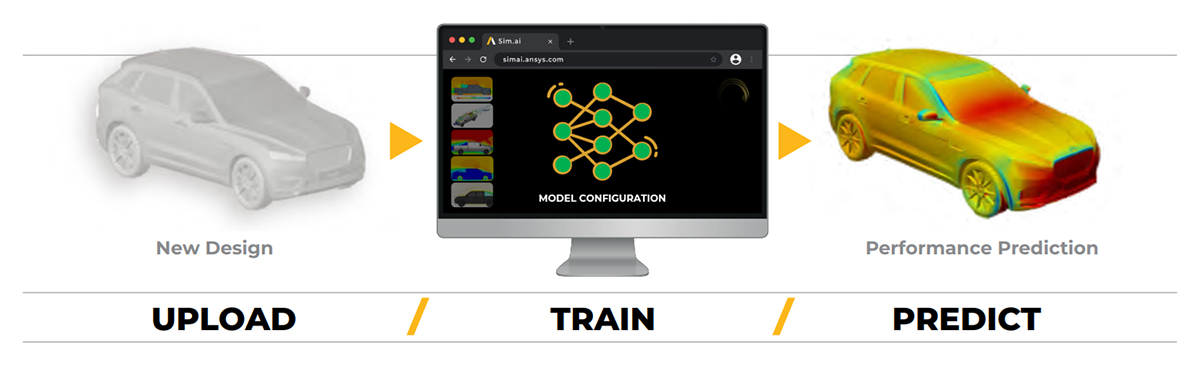

Another example of simulation democratization is the Ansys SimAI cloud-enabled AI platform, which enables you to train an AI model using previously generated Ansys or non-Ansys data and assess the performance of a new design within minutes. By combining simulation’s predictive accuracy with the speed of generative AI via the cloud, the software boosts model performance by 10-100X across all design phases.

Learn how a global drive manufacturer democratizes simulation in the blogs “Targeting Efficiency and Maximizing Simulation With AI and Automation” and “Danfoss Drives Supports Sustainability and Digital Transformation With Simulation.”

The Ansys SimAI cloud-enabled artificial intelligence (AI) platform can be employed in three simple steps: Upload, train, and predict.

Integrate Easily With Existing Systems

According to the CyberDB AI and cyber research databank, 90% of businesses rely on long-established older applications for core operations, even as organizations explore digital transformation opportunities with new technologies and AI.

PwC’s 2025 Digital Trends in Operations Survey respondents, including more than 600 operations executives and supply chain officers, cited integration with existing systems and data barriers — 42% and 37%, respectively — as top challenges in effectively scaling AI.

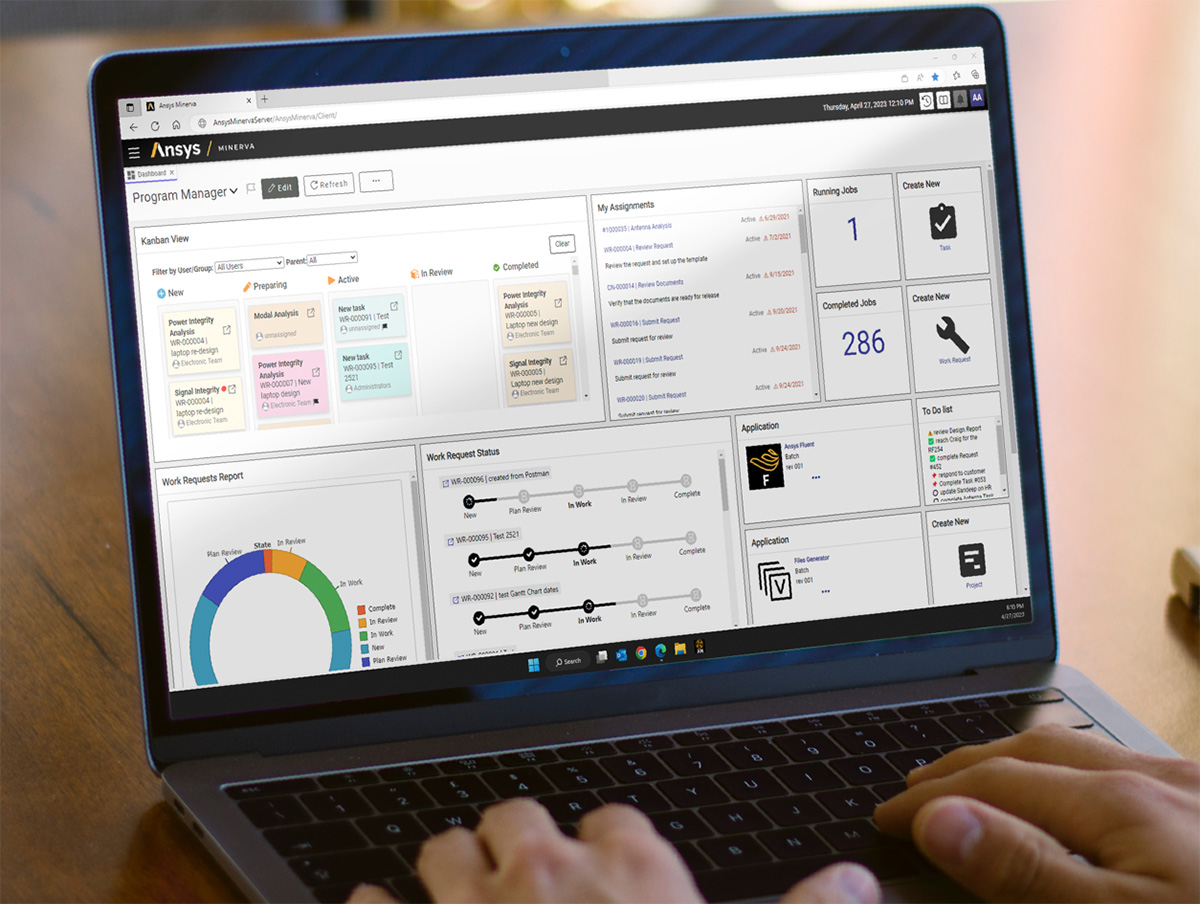

Minerva SPDM software is built upon an open ecosystem. It works with Ansys software, third-party tools, and existing CAD, product life cycle management (PLM), and enterprise resource planning (ERP) systems. In conjunction with robust, open solutions like the PyAnsys suite and optiSLang software, the Minerva platform offers an efficient way of solving simulation workflow integration and data management challenges in industry.

Learn how a global water pump manufacturer updated its workflow to streamline the electric machine design process and accelerate development in the case study “How Grundfos Streamlines Electric Machine Design and Development.”

Ansys Minerva simulation process and data management (SPDM) software enables you to manage simulation, data, and workflows from one central database across your organization.

Maximize Your Data With Simulation

Enhancing data management can break down silos and empower more informed decision-making, paving the way for a successful digital transformation. SPDM enables you to manage simulation, data, and workflows across your organization, spanning multiple departments, from one central database. Companies can create a digital thread throughout the product life cycle, increasing productivity, design success, and collaboration.

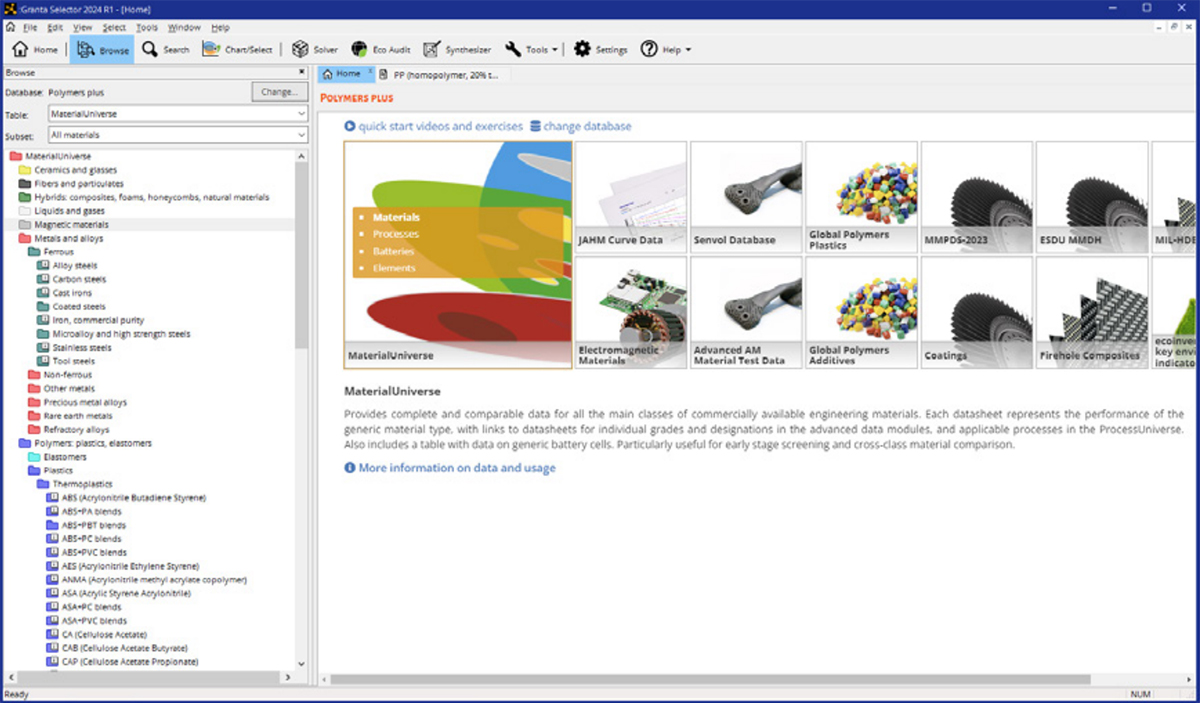

Likewise, the Ansys Granta materials information, selection, and data management product collection offers a range of software to inform decisions and compliance, improve collaboration, reduce costs, and drive innovation during product development and manufacturing.

Centralized data management software supports companywide decision-making, including factory operators, which could improve current imbalances in data accessibility. In the Manufacturing Leadership Council survey cited earlier, 77% of respondents reported that data-driven decision-making fell to plant leaders and managers, with only 33% observing factory floor employees with the same responsibility.

In addition, multiphysics simulation informs decision-making by enabling teams to model complex physics simultaneously and identify problems early. This minimizes physical testing and prototyping, which saves time, energy, cost, and material waste. Virtual prototyping empowers you to explore hundreds of design concepts in a fraction of the time that it takes to build and test physical prototypes.

Discover more about Minerva software and Granta software in the webinars “Introduction to Ansys Minerva, Powered by Aras” and “Intelligent Material Selection To Meet Engineering Challenges,” respectively.

The Ansys Granta materials information, selection, and data management product collection equips organizations to make informed decisions, enhance compliance, reduce costs, and drive innovation.

Let Simulation Help Your Digital Upgrade

Despite the primary integration challenges noted — skill gaps, existing outdated systems, and the need for enhanced data management — industrials are exploring digital tools to improve the customer experience. A Deloitte Research Center for Energy & Industrials report on the future of the digital customer experience (DCX) in industrial manufacturing and construction revealed that 93% of companies surveyed are experimenting with or implementing at least one DCX use case, and on average, companies are implementing four. Uses involve product monitoring, sharing designs, and applying analytics to support customer needs.

Similarly, an IDC study, sponsored by Ansys, found that 61% of manufacturers rank simulation as extremely/very important for product development.

Learn how Ansys can support your digital transformation by visiting our Industrial Processes and Equipment Simulation Software Solutions page.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.