-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

ANSYS ADVANTAGE MAGAZINE

DATE: 2019

Reducing the Strain of Additive Manufacturing

By Gregor Graf, Head of Engineering, Rosswag Engineering, Pfinztal, Germany

To optimize customer part geometries, reduce print failures and shorten development time, the Rosswag team adopted Ansys Additive Print, which simulates how materials will behave during the printing process. It predicts part shape distortion and stress, and designs optimal support structures for distortion compensation. Jobs are completed months earlier than the competition thanks to the software. The design of complex jobs can be finished in 20% less time and simple jobs accomplished in 50% to 60% less time.

As additive manufacturing's popularity surges, reliability issues that lead to part failure still linger. Leveraging Ansys Additive Print, Rosswag engineers determine strain prior to printing to eliminate distortion, stress and blade crashes, and reduce the number of builds.

Additive manufacturing (AM) — also known as 3D printing — is disrupting innovation and revolutionizing how global companies design and develop replacement parts, strengthen products and prototype new inventions. A global leader in metal AM services, Rosswag Engineering innovates functionally optimized metallic parts with incredibly intricate internal structures and complex shapes for numerous aircraft, energy, and oil and gas businesses.

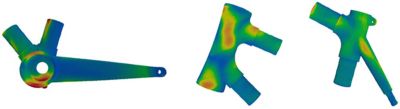

These three different bicycle frame parts, including the saddle clamp, have high tolerance requirements. The parts must be perfectly aligned for assembly. Ansys Additive Print helps significantly reduce distortion to fulfill all the requirements on time without the need to produce sample parts.

When Rosswag Engineering launched metal AM production, a highly complex project may have required up to 10 printing iterations to produce a desired geometry. Material behavior during the printing process remained unpredictable, which necessitated this trial-and-error approach. A single build (print) failure due to internal stresses and thermal distortion could cost the company thousands of dollars in development time, delay part delivery to the customer and destroy parts of the expensive AM machine.

To optimize customer part geometries, reduce print failures and shorten development time, the Rosswag team adopted Ansys Additive Print. Integral to the company's design process, Additive Print simulates how materials will behave during the printing process. It predicts part shape distortion and stress, and designs optimal support structures for distortion compensation. Jobs are completed months earlier than the competition thanks to the software's unprecedented efficiency. The design of complex jobs can be finished in 20% less time and simple jobs accomplished in 50%–60% less time.

"Leveraging Ansys Additive Print, the team reduces spending, increases reliability and delivers products to customers faster than ever before."

ANSYS ADDITIVE PREP

Ansys Additive Prep simplifies the process for orienting parts and developing advanced support structures without sacrificing machine time or print materials.

Once the part's optimal build orientation has been selected, the software detects the critical regions that require support and inserts the type of supports needed. Within seconds, it auto-generates a complex set of support geometries to reinforce the part during the printing process.

Simulation generates heat maps that identify potential strains and reveal how build orientations will impact support structures and build times.

COMBATING STRAIN WITH PRINT PROCESS SIMULATION

To calculate and predict distortion, residual stress, blade crashes and other printing issues, the team utilizes Additive Print. By detecting these issues early through simulation, engineers can determine the appropriate modifications and redesign the part, greatly reducing the number of builds. Featuring three strain detection modes with increasing levels of fidelity, Additive Print simulations are produced within a reasonable timeframe.

The team uses assumed uniform strain capabilities to analyze parts in an additive fashion, layer by layer, similar to how the printer builds up layers of material. This simulation provides fast turnaround and a good understanding of the pattern of the displacement that the part will experience.

Scan pattern strain simulation calculates the effects of the laser scan direction on every powder layer and provides the team with a bit more fidelity and refinement. This simulation accurately evaluates the elemental difference in the strain within the melt pool based on the direction of the laser's movement.

Using thermal strain simulation to perform a thermal–mechanical analysis, Rosswag designers calculate the heating and cooling of virtually every point within every scan vector of the part. With high-fidelity simulation — up to 15 μm resolution — this capability detects very fine features and differences in the strain, revealing part deformations with high accuracy.

Simulation also helps predict and identify areas on the part that have the highest potential for causing printing accidents, such as blade crashing. This occurs when a part being built lacks sufficient support structures and tilts up to collide with the recoater blade, damaging the part and potentially the machine. Adding support structures offsets thermal strain challenges to stabilize the part, preventing it from curling like a potato chip.

Based on the predictions of these three modes, engineers determine the part's optimal geometry compensation. Should distortion be detected, the team employs the software's automatic distortion compensation tool, which takes the desired geometry and reverse distorts it so that it reverts to the correct shape during the printing process.

The patented production process for adding highly complex blade structures with internal channel structures on conventional manufactured parts could be the next game changer for the aerospace and energy machinery industry.

GENERATING SUPPORT STRUCTURES TO PREVENT STRAIN

If simulation reveals a strain, the designers use this data to identify points in the geometry where a change in the structure will help mitigate the strain. Engineers generate supports using traditional geometry-based algorithms or use Additive Print's automatic generation of physics-based supports to print the part in its desired orientation.

In the next round of simulation, the software reveals the support structures' effectiveness and determines whether more stability may be required to confirm that the part will be built without unexpected distortions. Alternatively, the part's design may change to circumvent possible deformation. Prior to printing, the team will notify the customer of the proposed part geometry modifications and obtain approval.

Additive manufactured parts with specimens for mechanical testing on a build plate are shown here.

Next, the Rosswag team prints the part, incorporating supports if needed. Depending on the part's geometry, if there are critical or overhanging edges, the support structure will be used for heat transfer and to reinforce the layer that needs it. Following the print, designers verify the part's geometry by scanning and measuring it with a 3D laser scanner to certify that the part matches the geometry the customer approved.

"Using Additive Print for simple parts, the company saves about four build jobs per month. This streamlines Rosswag's operation and saves 100,000 euros (about $112,000) per year"

STREAMLINING THE WORKFLOW TO SAVE TIME AND MONEY

Additive Print remains integral to increasing the reliability of results, which can be reflected by the low number of printings needed to optimize parts. For example, if the team completes the job in two printings rather than four or five, the reliability of the production process is higher.

Using Additive Print for simple parts, the company saves about four build jobs per month. This streamlines Rosswag's operation and saves 100,000 euros (about $112,000) per year.

For complex parts, the simulation software saves the company 30,000 euros (about $33,000) per project, which equates to 10 printing jobs. So, as each job takes two to three days to complete, this saves 20 to 30 days in printing time.

USING ADDITIVE PRINT TO BUILD A BICYCLE

The Rosswag team first used Additive Print to assist a local college student who needed to fabricate a bicycle for a design competition. He created a sophisticated CAD design, and Rosswag helped him further improve his frame design.

The team challenged themselves to develop AM parts and connect them with parts not produced by AM, which were made of carbon fiber and composed one-third of the frame. This presented a design issue as simulation revealed deformation that prevented parts from being connected. Simulation also revealed minor deformations (cosmetic issues) on some of the outer surfaces.

To address the frame deformations, engineers modified the bike's geometry without adding support structures. Additionally, they adjusted the geometry of its outer surfaces for a polished appearance.

To print the parts, the team used its SLM 280HL selective laser melting system. After printing, Rosswag used a 3D scanning system to confirm that the printed part matched its geometry specifications.

Leveraging Ansys Additive Print to eliminate strain from their printing process has taken Rosswag's AM abilities to the next level. The company significantly reduces spending, increases reliability and delivers products to customers faster than ever before.

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.