-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

THEMENDETAILS

Was ist Fluid-Struktur-Interaktion?

Fluid-Struktur-Interaktion (FSI) beschreibt jedes Phänomen, bei dem ein Fluid mit einer beweglichen oder verformbaren Festkörperstruktur interagiert. Kräfte aus der Fluidströmung in Form von Druck oder Querkraft können dazu führen, dass der Festkörper seine Form ändert oder einer Starrkörperbewegung unterliegt. Änderungen in der Form oder Bewegung eines Festkörpers können wiederum das Fluidströmungsfeld verändern. FSI ist eine Art Multiphysik-Interaktion, die Strömungslehre und Festkörpermechanik einbezieht.

Ingenieur*innen verwenden Simulationstools und Tests, um die Fluid-Struktur-Kopplung zu untersuchen und die realen Interaktionen ihrer Produkte zu verstehen, wenn Fluide um sie herum oder durch sie hindurch fließen. Diese Interaktionen können sich auf die Leistung der Produkte, die sie konstruieren oder instand halten, sowie auf deren Robustheit auswirken, wenn die Verformungen zu groß werden oder zu häufig auftreten. Windgeräusche eines vorbeifahrenden Autos, die Auf- und Abwärtsbewegung der Flügel eines Verkehrsflugzeugs während des Fluges oder die Art, wie das Herz Blut pumpt, sind Beispiele für FSI in der realen Welt. In schweren Fällen können FSI zu Strukturversagen, Verletzungen oder zum Tod führen. Der Zusammenbruch der Tacoma Narrows Bridge 1940 durch aeroelastisches Flattern und der Kühltürme der Ferrybridge Power Station 1965 durch Windturbulenzen sind zwei bekannte Beispiele. Eine häufigere Form von FSI, die zu Versagen führen kann, sind Druckstöße – ein lautes Klopfen, das durch plötzlich auftretenden Wasserdruck in Rohren verursacht wird.

Ingenieur*innen kombinieren Software-Tools für Computational Fluid Dynamics (CFD) und Finite-Elemente-Analyse (FEA), um FSI-Modelle zu erstellen, die das Verhalten beider Bereiche vorhersagen, wenn Lasten über die Fluid-Festkörper-Grenzschicht übertragen werden oder Änderungen in Form oder Position der Fluid-Festkörper-Grenzschicht auftreten. Die Verwendung von FSI-Analysen nimmt aufgrund verbesserter Kopplungsalgorithmen und verbesserter Rechenleistung zu.

Verschiedene Arten von Fluid-Struktur-Interaktionen

Die Art der FSI, die ein System erfährt, hängt von der Art der Strukturverformung des Festkörpers ab und davon, wie stark sich jede Physik auf die andere Physik im System auswirkt.

Einseitige und zweiseitige Kopplung bei Fluid-Struktur-Interaktion

FSI-Studien umfassen die Übertragung von Kräften von einem Fluid auf einen Festkörper sowie Änderungen der physikalischen Eigenschaften der beiden Bereiche, die sich aus ihrer Interaktion ergeben. Ingenieur*innen unterteilen die Kopplung in die folgenden zwei Kategorien.

- Einseitige Kopplung

Die häufigste Art der einseitigen Kopplung, auch als schwache Kupplung bezeichnet, trifft auf, wenn ein System Kräfte von der Fluidströmung auf den Festkörper überträgt, aber die Reaktion des Festkörpers einen vernachlässigbaren Einfluss auf das Verhalten der Fluidströmung hat. Dies liegt in der Regel daran, dass die Strecke, die sich der Festkörper verformt, relativ zu dem Fluidvolumen, das die Verformung verursacht, klein ist. Flügel von Rennwagen sind ein gutes Beispiel für einseitige Kopplung. Der Luftstrom über einen Flügel erzeugt Anpressdruck auf den Flügel, aber der Flügel ist starr genug, dass diese Kräfte die Form des Flügels nicht verändern.

Einseitige Kopplung kann auch auftreten, wenn die Bewegung eines Objekts einem Fluid Impuls verleiht oder entzieht, wodurch Geschwindigkeit und Druck des Fluidbereichs geändert werden, ohne spürbare Änderungen an der Form oder Bewegung des Objekts durch das umgebende Fluid zu verursachen. Ein gutes Beispiel dafür ist ein elektrischer Lüfter. Die Bewegung der Lüfterblätter erhöht die Geschwindigkeit der durch den Lüfter strömenden Luft, ohne die Form der Lüfterblätter erheblich zu verändern.

Simulationen einseitiger Kopplung wenden die Druck- und Querkräfte einer gelösten CFD-Simulation auf die Fluid-Festkörper-Grenzschicht eines FEA-Strukturmodells an und lösen dann die Spannung und Dehnung im Strukturbereich, oder die Geschwindigkeit des Festkörpers an der Fluid-Festkörper-Grenzschicht wird als Randbedingung für das CFD-Modell verwendet. In beiden Fällen wird die Kraft oder Geschwindigkeit nur von einem Bereich in einen anderen übertragen.

- Zweiseitige Kopplung

Die häufigste Form zweiseitiger Kopplung, oft auch als starke Kopplung bezeichnet, tritt auf, wenn die Kräfte des Fluidbereichs auf den Festkörper dazu führen, dass der Festkörper so stark verformt wird, dass sich Druck oder Geschwindigkeit des Fluids ändern. Diese Änderungen verändern dann die Fluidkräfte, die die Verformung und Bewegung verändern, und dadurch wiederum die Strömung.

Simulationen zweiseitiger Kopplung verwenden Algorithmen, um die Verformung des Festkörpers zurück in das CFD-Modell zu übertragen. Manchmal, wenn diese Änderungen signifikant genug sind, wird das Netz der Fluidbereiche verzerrt und ist nicht mehr gültig. Die Software verwendet einen automatisierten Prozess namens Neuvernetzung, um das Netz neu zu erstellen. In den extremsten Fällen ändert sich die Topologie des Fluidbereichs, wenn sich Passagen öffnen oder schließen.

Bei Simulationen zweiseitiger Kopplung können zwei verschiedene Methoden für Iterationen zwischen den Lösungen im CFD- und FEA-Solver verwendet werden, während das Modell die Zeit durchschreitet. Beim expliziten oder sequenziellen Ansatz werden Lasten und Verformungen nur einmal pro Zeitschritt übertragen. Der implizite oder simultane Ansatz löst sowohl die Fluid- als auch die Struktursimulationen gleichzeitig, tauscht Lasten und Verformungen aus und löst dann im gleichen Zeitschritt erneut, bis die Lösung konvergiert. Das System wechselt dann zum nächsten Zeitschritt.

Die explizite Methode ist einfacher einzurichten und benötigt weniger Rechnerressourcen, da es nur eine Lösung pro Iteration gibt. Sie ist jedoch weniger stabil als die implizite Methode, und die Modelle können voneinander abweichen. Die meisten Ingenieur*innen wählen den impliziten Workflow, wenn sie zweiseitig gekoppelte Systeme modellieren und eine höhere Genauigkeit wünschen, als die explizite Methode hergibt.

Arten von Strukturverformung

Eine andere Art, wie Ingenieur*innen Probleme mit Fluid-Struktur-Interaktion kategorisieren, besteht darin, die Art der Verzerrung zu bestimmen, die der Strukturbereich durchläuft. Benutzende von Simulationstools verwenden diese Informationen, um die richtigen Modellierungsansätze und Algorithmen für den Datenaustausch zwischen CFD- und FEA-Solvern zu bestimmen.

Die häufigsten Arten der Verformung sind:

- Geringe Verformung

Modelle mit geringen Strukturbereichsverschiebungen verwenden Simulation einseitiger Kopplung. Dieser Ansatz löst zuerst das CFD-Modell und wendet dann die Kräfte auf das Strukturmodell an. In dieser Situation ist keine Änderung der Form der Fluid-Struktur-Grenzschicht erforderlich.

Manchmal üben Schwingungen in der Fluidströmung geringe, zyklische Kräfte auf eine flexible Oberfläche des Strukturteils des Systems aus, und der Festkörper reagiert, indem er vibriert. Diese Vibration erzeugt dann Schallwellen, die durch das Fluid gehen, ohne die allgemeinen Strömungseigenschaften zu verändern. Aerodynamik-Ingenieur*innen bezeichnen diese Art der Fluid-Struktur-Interaktion als Akustik-Struktur-Interaktion (ASI).

In der Hydrodynamik kann eine Druckwelle in einem Rohr oder Kanal nachhallen und Vibrationen in den Festkörperkomponenten verursachen. Diese Schwingung wird als Druckstoß bezeichnet. Sowohl ASI als auch Druckstöße erzeugen Geräusche und können manchmal Strukturkomponenten ermüden.

- Große Verformung

Wenn die Verformung oder Bewegung des Festkörperbereichs groß genug ist, um die Fluidströmung zu ändern, ist zweiseitige Kopplung erforderlich. Darüber hinaus müssen Ingenieur*innen ihre Simulation möglicherweise so einrichten, dass sie Methoden verwenden, um die CFD- und FEA-Netze zu verzerren oder sogar die Geometrie in beiden Bereichen neu zu vernetzen. Die Geschwindigkeit der Verzerrung oder Bewegung bestimmt auch die Zeitschrittgröße für jede Solver-Iteration.

- Große schwingende Verformung

Wenn die Änderungen der Fluidkräfte eine Eigenfrequenz in der Struktur anregen, können im System große Schwingungen auftreten. Diese Schwingungen können weiter zunehmen, wenn die Fluidströmung dem System mehr Energie zuführt. Aerodynamiker*innen nennen diese Art der Kopplung Aeroelastizität.

Das Versagen der Tacoma Narrows Bridge ist ein Beispiel für aerodynamische Lasten, die Vibrationen in einer Struktur bis zu dem Punkt auslösen, an dem die Struktur versagt.

- Starrkörperbewegung

Komplexe zweiseitige Fluid-Struktur-Interaktionen können auch bei Strukturkomponenten auftreten, die sich nicht verzerren, aber ein Moment haben. Diese Starrkörperbewegung erfordert immer noch zweiseitige Kopplung und Neuvernetzung des Fluidbereichs.

- Verformung durch Körperlast

Körperlasten durch Schwerkraft oder elektromagnetische Felder können zusammen mit thermischen Belastungen den Festkörperbereich verzerren, der ein FSI-System beeinflusst. Aktoren und Antriebswellen belasten den Strukturbereich ebenfalls. In biologischen Systemen bewegen die Entspannung und Kontraktion von Muskeln Fluide im Körper. Ingenieur*innen sollten sicherstellen, dass sie alle Körperlasten in ihren FSI-Modellen verstehen und berücksichtigen.

Andere Physiken mit Fluid-Struktur-Interaktion

Wenn eine Simulation andere Lasten im Fluid- oder Strukturbereich enthält, wird das FSI-System zu einer komplexeren multiphysikalischen Simulation. Ein häufiges Beispiel hierfür sind Fluidelemente mit mikroelektromechanischen Systemen (MEMS). Sie funktionieren durch Kopplung von Elektro-, Elektrostatik-, Magnet-, Thermo-, Fluid-, und Strukturphysik in einem Gerät.

Die häufigste Physik, die Ingenieur*innen in FSI-Studien verwendet haben, ist konjugierte Wärmeübertragung. Bei dieser Art von Simulation werden CFD-berechnete Temperaturen und Geschwindigkeiten verwendet, um die Wärmestromdichte zwischen den Festkörper- und Fluidbereichen zu bestimmen.

Anwendungen für FSI in verschiedenen Branchen

Fluid-Struktur-Interaktion tritt in vielen Systemen in verschiedenen Branchen auf, aber einige stechen hervor, da Fluidströmung in ihren Produkten eine wesentliche Rolle spielt. Im Folgenden finden Sie eine Liste der Branchen, in denen FSI eine wichtige Rolle bei der Steigerung von Robustheit und Optimierungsleistung spielt.

Luft- und Raumfahrt

Wenn Sie schon einmal aus dem Fenster eines Passagierflugzeugs geschaut und beobachtet haben, wie sich die Struktur eines Flügels bewegt, haben Sie zweiseitige Kopplung mit großer Verformung beobachtet. In der Luft- und Raumfahrt werden viele Geräte hergestellt, die durch die Atmosphäre transportiert werden, was FSI zu einem wesentlichen Aspekt bei Konstruktion und Wartung macht. Die Interaktion zwischen dem Fluid- und dem Festkörperbereich wird noch kritischer, wenn Luft- und Raumfahrzeuge sich schneller bewegen als Schall- und Stoßwellen entstehen, was erhebliche Kräfte erzeugt.

Einige häufige Beispiele für die Fluid-Struktur-Interaktion in der Luft- und Raumfahrt, die Ingenieur*innen am Herzen liegen, sind:

- Aeroelastizität von Flügeln

- Starrkörperbewegung von Gegenständen wie Reservekraftstofftanks und Waffen, die vom Flugzeug abfallen

- Ballistische Flugbahnen von Gegenständen durch die Luft

- Lasten auf Steuerflächen

- Aufblasen von Fallschirmen und Flächenfallschirmen

- Schwankungen von Kraftstoff in Tanks

- Akustische und aerodynamische Belastungen an Raketendüsen

Automobilindustrie

Autos fahren auch durch die Atmosphäre, und sie bewegen mit Antrieben und Klimaanlagen Flüssigkeiten und Gase. Wenn Sie jemals ein Auto mit Schiebedach gefahren sind, haben Sie eine Fluid-Struktur-Interaktion erlebt, als Sie bei bestimmten Geschwindigkeiten ein Geräusch hörten. Die meisten FSI in der Automobilindustrie sind einseitig, da die Fahrzeugstrukturen in der Regel starr sind.

Biomedizin

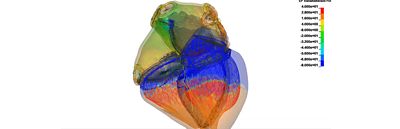

Der menschliche Körper ist ein komplexes Fluid-Struktur-System, in dem viele Strukturkomponenten flexibel sind. Sowohl Herzkammern als auch Herzklappen sind großartige Beispiele für Fluid-Struktur-Kopplung in natürlichen Systemen. Herzmuskeln ziehen sich zusammen und dehnen sich aus, um das Volumen der Herzkammer zu verändern, wodurch der Blutdruck erhöht und das Blut durch die Herzklappen gedrückt wird. Herzklappen haben flexible Segel, die sich öffnen und schließen lassen, um Blutfluss zu ermöglichen oder zu blockieren. Sie öffnen sich, wenn der Druck in der Herzkammer ansteigt, und schließen sich, wenn der Druck abfällt.

Ein Beispiel für eine biomedizinische FSI-Simulation eines menschlichen Herzens mit dem Tool PyAnsys-Heart

Nicht-militärische Bauwerke

Gebäude, Brücken und andere Bauten interagieren mit Wind und Wasser und zeigen Fluid-Struktur-Interaktionen. Sehr hohe Gebäude schwanken nicht nur bei starkem Wind, sondern erfahren auch zweiseitige Kopplung, da sie das Windmuster verändern, wenn sie sich bewegen.

Clean Tech (Saubere Technologie)

Zwei der häufigsten Beispiele für FSI in Clean-Tech-Produkten sind das Verhalten von Solarpaneelen und Windturbinen. Solarpaneele können einseitige Kopplung aufweisen, wenn sich die Paneele nicht bewegen und starr sind, oder zweiseitige Kopplung, wenn die Paneele biegsam sind oder Aktoren zur Ausrichtung verwenden. Die Schaufeln von Windturbinen sind flexibel, biegen sich aufgrund von Schwerkraft und Windlasten und drehen sich, um ihre Ausrichtung zum Wind zu ändern.

Turbomaschinen

Die Luft oder der Dampf, der durch Turbomaschinen strömt, interagieren sowohl mit den statischen als auch mit den rotierenden Festkörperkomponenten innerhalb der Geräte. Ingenieur*innen verwenden FSI-Simulationen, um Aeroelastizität, erzwungene Vibrationen, Ventile und Dichtungen zu bewerten. FSI-Studien zu Turbomaschinen sind komplex, da die Geschwindigkeiten, Temperaturen und Drücke hoch sind.

Fluidsysteme

Viele Produkte haben Systeme, die die Strömung von Flüssigkeiten und Gasen durch das Gerät oder die Maschine steuern. Die meisten Ventile, Dichtungen, Sensoren und Pumpen, die in Fluidsystemen verwendet werden, unterliegen mindestens einseitiger Fluid-Struktur-Kopplung und können zur Ausführung ihrer vorgesehenen Aufgaben zweiseitige Kopplung verwenden.

Häufige Herausforderungen und Empfehlungen für die FSI-Simulation

Die Simulation von Fluid-Struktur-Interaktion ist schwierig, da sie zwei unterschiedliche Physiken modelliert, die Benutzende optimal einrichten und ausführen müssen, und weil der Umgang mit ihrer Kopplung kompliziert sein kann. Im Folgenden finden Sie eine Liste der häufigsten Herausforderungen sowie einige Empfehlungen zur Bewältigung dieser Herausforderungen.

Auswahl des richtigen Tools für jede Physik

Die Auswahl der richtigen Simulationstools für CFD und strukturelle FEA ist die erste Herausforderung bei der Durchführung von FSI-Simulationen. Benutzende benötigen ein einfach zu verwendendes Tool für Fluidsimulationen, das über die richtige Mischung aus numerischen Methoden verfügt, um das Verhalten des Fluidenbereichs zu erfassen, effizient zu lösen, und das FSI unterstützt. Beispielsweise entscheiden sich Benutzende, die mit Turbomaschinen arbeiten, häufig für die Software Ansys CFX für Computational Fluid Dynamics, da sie in dieser Branche sehr leistungsstark sind. Ingenieur*innen, die andere Problemklassen modellieren, werden sich aufgrund ihrer großen Auswahl an Turbulenzmodellen, robusten Vernetzung und Neuvernetzung und fortschrittlichen CFD-Funktionen eher auf die Simulationssoftware Ansys Fluent konzentrieren.

Bei Strukturen benötigen Benutzende eine robuste, universelle Plattform wie die Software Ansys Mechanical zur Finite-Elemente-Analyse, die sowohl lineare als auch nichtlineare Feststoffe und Geometrie präzise modelliert und anspruchsvolle Lasten sowie die branchenweit umfassendsten Funktionen bietet. Benutzende sollten mit einem Tool arbeiten, das eine benutzerfreundliche und programmierbare Benutzeroberfläche einschließt, die die Modellierung sowohl ein- als auch zweiseitiger Kopplung unterstützt.

Ein gutes Beispiel für ein umfassendes Tool zur Verbindung unabhängiger Physik ist die Software Ansys System Coupling zur Verbindung von Physik-Solvern. Sie bietet Funktionen für ein- und zweiseitige Kopplung, Scripting, Datenzuordnung und Datenaustausch. Fluid-Struktur-Kopplung macht sie zu einem führenden Tool für Ingenieur*innen, die diese spezielle Art von Systemkopplung simulieren.

Fachwissen für Fluide und Strukturen

Fluid- und Struktursimulation unterscheiden sich sehr stark, ebenso wie die Tools für CFD und Struktursimulation. Einige Ingenieur*innen haben ein tiefes Verständnis für beide Bereiche, aber in der Regel haben sie eine Stärke in dem einen und eine flüchtige Bekanntschaft mit dem anderen. Eine Möglichkeit, dabei zu helfen, besteht darin, beide Tools vom selben Anbieter zu wählen, wie z. B. Ansys, von denen auch umfassende Schulungskurse und Webinare angeboten werden, um Benutzenden zu helfen, sich mit beiden Physiken vertraut zu machen. Wenn das Toolset außerdem Skriptfunktionen wie das Tool PyAnsys für Python-Zugriff über Ansys-Software bereitstellt, kann ein Experte die Automatisierung für beide Physiken einrichten.

Die beste Möglichkeit, Fachwissen in einem Bereich zu finden, besteht jedoch darin, als Team mit einem Experten in dem Bereich zusammenzuarbeiten, den Sie nicht so gut kennen. Verwenden Sie anschließend Tools zur Verwaltung von Simulationsdaten, wie z. B. die Software Ansys Minerva für den Simulationsprozess und Datenverwaltung, um zu kollaborieren und Modelle und Durchläufe zu verfolgen.

Entscheidung zwischen ein- und zweiseitiger Kopplung

Manchmal ist nicht klar, ob ein bestimmtes Problem der Fluid-Struktur-Interaktion ein- oder zweiseitige Kopplung erfordert. Im Zweifelsfall ist der beste Ansatz, mit einer einseitigen Lösung zu beginnen, da diese einfacher und effizienter zu lösen ist. Wenn die Lösung zeigt, dass zweiseitige Kopplung erforderlich ist, machen Sie dies.

Umgang mit numerischer Instabilität

Einige FSI-Situationen sind instabil, oder Modelle sind mit dem falschen Netz oder den falschen Einstellungen konstruiert, was zu Nichtkonvergenz führt. In diesen Situationen ist es am besten, mit Tools aus dem Ansys-Portfolio zu arbeiten, die mehrere numerische Methoden zur Stabilisierung sowie umfassende Schulungen und Unterstützung bieten.

Zugriff auf ausreichende Rechenressourcen

CFD-Simulationen sind schon für sich genommen rechenintensiv. In Verbindung mit struktureller FEA können sie eine erhebliche Menge an Ressourcen brauchen, insbesondere für implizite zweiseitige Kopplung. Um diesem Problem entgegenzuwirken, sollten Sie sich für Solver entscheiden, die High-Performance-Computing unterstützen, wie Ansys CFX, Fluent und Mechanical, die sich mit paralleler Verarbeitung und GPUs gut skalieren lassen. Darüber hinaus sollten Sie sich mit der Nutzung Cloud-basierter Ressourcen für High-Performance-Computing wie Ansys Cloud befassen, um die benötigte Kapazität bereitzustellen, wann immer Sie sie benötigen.

Zugehörige Ressourcen

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.