Case Study

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

“Even with powerful workstations, on-premises limitations are unavoidable. The cloud eliminates these capacity and speed constraints, offering productivity gains beyond what local hardware can achieve. Building an on-site cluster is cost-prohibitive. Cloud provides the flexibility to scale on demand. Ansys Access on Microsoft Azure software makes accessing [the] cloud easy.”

— Andrew Hobbs, Ph.D. Director of Advanced Technologies / Astec Digital

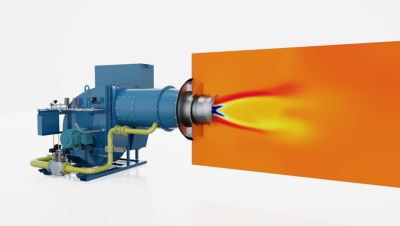

CFD simulation of hydrogen combustion simulation of an Astec Phoenix® Talon 2 burner showing contours of OH

Astec is a global leader in manufacturing equipment for road building, aggregate processing, and concrete production. The company’s mission is to design and build state-of-the-art equipment and enable their customers to achieve industry-leading results profitably.

Challenges

Astec requires the flexibility to quickly scale resources to meet diverse project demands. Currently, the company is working on a hydrogen burner model that involves complex CFD simulations with around 35 million elements. This project is an evolution of their very successful Phoenix® Talon 2 burner, and with the high demand for alternative fuels, they must quickly innovate to adapt to new fuels like hydrogen. To stay competitive, Astec has used CFD extensively to develop a single burner that can run on many types of fuel. However, as demand for simulation at Astec continues to grow, their on-premises workstations could reach hardware limits in the near future, posing a challenge for handling these intensive computations.

Astec had already experienced success with the Ansys Cloud Direct™ cloud-based simulation solution to overcome hardware challenges in the past, and the company was interested in migrating to the new generation of Ansys Cloud offerings. Astec was interested in boosting their capacity and speed, as well as having a solution to scale up and down in addition to their on-premises workstations. Purchasing a cluster is expensive, and the company needed a cloud solution to keep their focus on engineering. In the future, Astec seeks to democratize access to simulation across teams and increase accessibility while ensuring costs are controlled by sharing virtual machines across departments.

Technology Used

- Ansys Access on Microsoft Azure™ cloud engineering solution

- Ansys Fluent® fluid simulation software

Engineering Solutions

Astec thrives on reducing hardware bottlenecks by focusing on engineering and developing industry-leading products. Their combustion model required a lot of memory bandwidth and good meshing. Leveraging the cloud and high-performance computing (HPC) meant they could run simulations faster and keep the workstations “free,” enabling them to leverage other tools in parallel while not straining their on-premises resources. With Ansys tools, the end user can run a combustion job on the cloud and do finite element analysis (FEA) on their local workstations to ensure business continuity.

“Extra capacity massively increases productivity. By removing the hardware bottleneck, we are just able to do a lot more. We are not constrained by workstations,” Andrew Hobbs, director of advanced technologies at Astec, says.

Storage is also very important for Astec, as they were able to plug their storage drive from Microsoft Azure directly into Ansys Access on Microsoft Azure software.

“Just as an example, when I’m running Ansys Fluent software on my workstation and just want to remesh my model and my storage is full, I must free up some space on my workstation, and it really takes time. So, I can go to Ansys Access on Microsoft Azure software, and I do it seamlessly on the cloud. It saves me a lot of time, and I can do my other jobs on my workstation, like vibration analysis, etc.,” Dipika Gongal, senior simulation engineer at Astec, said.

Benefits

- An easy onboarding process, with all simulations available in a single environment

- Fast data transfer: Astec can leverage their existing long-term data storage and save time when using the cloud. They used external Microsoft Azure storage within their Azure subscription and attached it directly to the virtual machine running Ansys Access on Microsoft Azure software. This was considered a “much easier option” and a great evolution compared to Astec’s previous tools.

- Hours saved for each simulation: Astec achieved massive time savings compared to on-premises solutions. Several hours could be saved for each simulation, and some simulations that could not be performed on on-premises workstations were made possible through the cloud.

- Unrestricted capacity to scale to meet project demands

- The ability to control costs for both hardware and software, plus avoiding paying for costly workstations for only occasional users

Astec is happy with the evolution of Ansys Cloud products and believes it could be a game changer in the near future. Ansys Cloud solutions enable them to focus on their engineering goals and democratize simulation easily.

“Having gone from Ansys Cloud Direct software to Ansys Access on Microsoft Azure software, we have seen big improvements. Built-in metric tracking and overall ease of use will help drive greater adoption of cloud HPC,” Hobbs said.

Company Description

Astec Industries has been a global leader in providing innovative "Rock to Road™" solutions since 1972, specializing in equipment for asphalt road building and aggregate processing. Guided by the vision statement, "To build industry-changing solutions that create life-changing opportunities," Astec is committed to customer-driven innovation, placing both customers and employees at the forefront. Rooted in its purpose of "Built to Connect," the company continues to shape communities through cutting-edge solutions for road construction, materials processing, concrete mixing, and forestry and recycling, embodying a steadfast commitment to quality, global impact, and the well-being of its valued employees.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.