How Can We Help You?

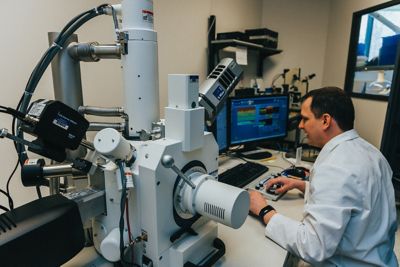

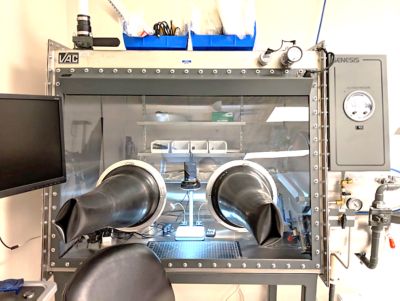

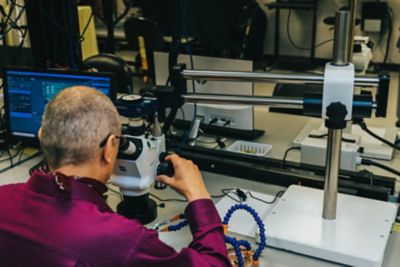

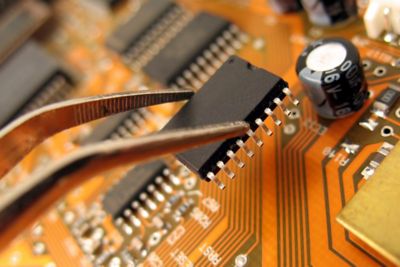

Our team has been solving product reliability problems for nearly 20 years across all industry verticals that use, design, or manufacture electronics. Delivering over 300 projects per year, our engineers and scientists see and solve more electronics reliability issues in a year than a product engineer will see in a career. This extensive experience lets us quickly identify the right approach to solving reliability problems and help implement cost-effective and timely solutions.

Although our customers come to us with a wide variety of challenges, the following list describes the most common reasons customers seek our help:

- Identify the root cause of failures in tests or the field and how to prevent those failures from reoccurring.

- Assess and quantify the reliability risks associated with a new product design to help inform design, test, support, and warranty decisions.

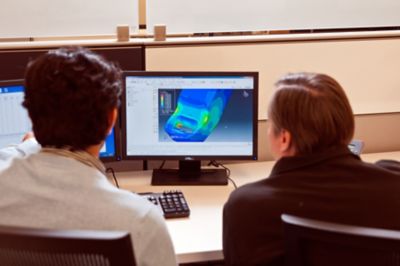

- Define and quantify the reliability impact of design choices at the system or component level.

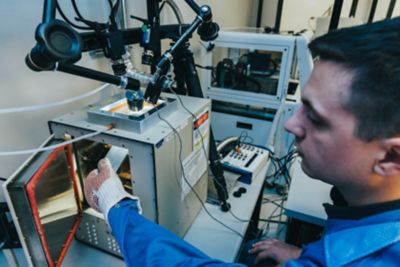

- Optimize the component or system reliability testing approach to minimize test time and cost.

- Implement simulation approaches to reliability prediction at any stage of the design process to avoid reliability surprises.

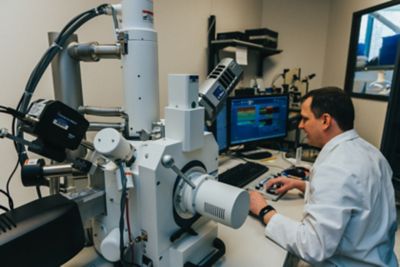

- Enable more accurate simulation through expert materials characterization and modeling.

- Educate design teams on the best practices of reliability physics and design for excellence, helping reliability from the earliest stages of product development.