Some kids dream of being a race car driver; others may dream of being a race car designer. Thanks to student competitions like the Institution of Mechanical Engineers (IMechE) Formula Student event, those dreams can become reality earlier than ever. Organized by IMechE, Formula Student is a prominent educational engineering competition in Europe. It challenges university teams to design, build, and race small single-seat formula-style cars, judged not only on speed but on innovation, efficiency, manufacturability, and business viability. The goal is to provide engineering students with a real-world platform to apply theory, conduct experiments, and innovate in a competitive environment.

Competing teams are scored across design, cost, and performance categories, with the goal of simulating the complete life cycle of a motorsport engineering project — from concept to commercialization. For many students, it’s a step toward careers in automotive design, motorsport, and advanced engineering industries.

Right on Track

When the Formula Student Bizkaia (FSB) team from the University of the Basque Country (UPV/EHU) rolled onto the track at Formula Student UK 2025, team members brought with them more than just a race car. They brought nearly two decades of engineering evolution, a commitment to innovation, and a deep reliance on simulation technology that powered their most successful season yet.

The team’s all-electric car, the FSB2025, didn’t just perform — it dominated. Against top engineering universities from around the world, FSB emerged as the overall winner of Formula Student UK 2025, marking a milestone achievement for the team.

Behind this success was a blend of teamwork, ingenuity, and simulation-driven design made possible by the advanced solutions from Ansys, part of Synopsys, and support from an Ansys Student Team Partnership.

Like all Formula Student teams, FSB’s mission extends far beyond the racetrack. After six years competing with combustion-powered cars, FSB made a bold decision in 2012 to go fully electric. It was a move driven not by trend but by analysis. Simulation work had shown that while electric powertrains added weight and complexity, they offered far greater potential — from instant torque and higher efficiency to the ability to control each motor independently.

A team member does a torsional stiffness analysis of the composite monocoque using Ansys Mechanical (Static Structural) software, with composite layup definition carried out in the Ansys ACP (Pre) application.

“This strategic shift was driven by the pursuit of greater technological potential, improved performance, and a more sustainable approach to motorsport,” says Ibone Mancisidor, technical manager of the team and an industrial engineering student specializing in mechanical engineering at UPV/EHU.

That decision shaped everything that followed. Over the next decade, the team refined its electric vehicle architecture, culminating in another major breakthrough in 2022 with the FSB2022, its first all-wheel-drive (AWD) design. The team’s engineers used extensive simulation to evaluate the impact of torque distribution, traction, and regenerative braking, all key parameters for achieving optimal vehicle dynamics.

By 2025, those years of innovation came together in FSB2025, a car that perfectly balanced performance, reliability, and design maturity.

A Year of Innovation

The development of Team Bizkaia's FSB2025 vehicle followed a structured, yearlong process aimed at delivering a high-performance car ready for competition.

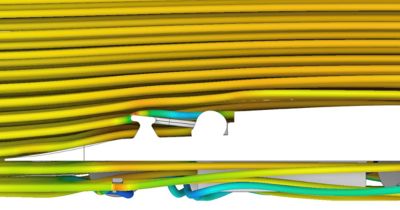

The design phase itself was divided into three main stages: viability, pre-design, and detailed design. During these stages, each department — chassis, aerodynamics, suspension, electronics, and powertrain — collaborated to ensure that the individual subsystems were not only optimized but seamlessly integrated with one another as the team leveraged Ansys Mechanical structural finite element analysis (FEA) software and the Ansys Workbench simulation integration platform add-in, the Composite PrepPost (ACP) tool, enabling the team to virtually test its ideas and refine them based on precise data.

“We use Ansys Mechanical as our primary simulation tool,” explains Mancisidor. “It’s essential for validating any component we design and manufacture, allowing us to analyze its structural performance under realistic conditions before production.”

Once the design was finalized, the focus shifted to manufacturing and assembly. This phase required precise coordination across departments to align production timelines and guarantee that all components were properly fitted. Since the team handled much of the manufacturing process itself, including the composite monocoque — or main structural shell of the car — maintaining accuracy and consistency was critical.

Finally, the car entered the testing and validation phase. Track testing was crucial for collecting performance data, fine-tuning setups, and ensuring that the car met the competition's regulations. This rigorous testing helped identify any issues early, allowing for adjustments before the vehicle faced real-world challenges at Formula Student UK. Through this iterative, collaborative process, Team Bizkaia successfully turned its vision for the FSB2025 into a race-ready reality.

From Simulation to the Track

Ansys software played a critical role in the design and development of Team Bizkaia’s FSB2025 vehicle. Among the tools used, Mechanical software served as a primary resource for conducting FEA to evaluate the structural performance of components. This enabled the team to simulate how parts of the car like the monocoque would respond to realistic loading conditions, helping ensure that the car met performance, strength, and safety standards before manufacturing began.

Additionally, the ACP tool was instrumental in working with the composite materials used in the chassis and aerodynamics systems. The software enabled the team to define the layup configurations of the monocoque, including material properties, ply orientations, and stacking sequences. This level of precision helped engineers optimize the structure for stiffness and weight efficiency while maintaining safety requirements.

The integration of Ansys simulations didn’t just improve accuracy — it delivered measurable efficiency gains. Instead of producing physical samples for every potential material configuration, simulations provided accurate predictions, helping reduce material use by approximately 30%. Furthermore, Ansys tools shortened the design cycle, enabling the team to enter the testing phase earlier, a crucial advantage in the run-up to competition season.

A structural analysis of the vehicle upright is performed using Ansys Mechanical (Static Structural) software. (The upright is a critical suspension component that connects the suspension system to the wheel assembly and is part of the vehicle’s unsprung mass, making weight optimization essential.)

“Simulation allowed us to focus our resources where they mattered most,” says Mancisidor. “We could evaluate multiple design options quickly, find the optimal solution, and move forward with confidence.”

Team Bizkaia celebrating its Formula Student UK 2025 win

Achieving Success at Formula Student UK 2025

When the FSB2025 hit the Silverstone circuit in July 2025, it represented the culmination of a year’s worth of hard work, simulation, and collaboration.

The car’s balance of lightweight design, high stiffness, and reliable performance helped the team outperform top international competitors — earning it the overall championship title for the first time in team history.

The victory marked not only a technical triumph but a validation of the team’s simulation-driven workflow. Every lap and test at Silverstone confirmed what months of analysis in Ansys software had predicted.

Racing Toward Tomorrow

Now entering the 2025-26 season, the Formula Student Bizkaia team is already designing the FSB2026, building on everything that the team learned from its championship-winning car. As technical manager, Mancisidor is guiding the next generation of engineers toward even more advanced simulation techniques.

The team plans to refine its use of simulation tools to push the limits of efficiency and performance. “Our next step is to start exploring impact analysis for composite materials,” says Mancisidor. Dynamic impact simulations will enable the team to predict how energy is absorbed during collisions, helping FSB design a monocoque that not only performs under pressure but protects the driver in extreme scenarios, an essential factor in real-world motorsport.

The team is focused on mentoring new members to ensure continuity and foster a culture of innovation. By sharing the knowledge and expertise gained during the development of the FSB2025, team members aim to empower the next generation of engineers to take on even greater challenges.

“Being part of Formula Student Bizkaia has been a deeply rewarding experience. Ansys gave us the capability to simulate, test, and truly understand how our designs behave in the real world. It’s helped us grow not just as students but as future engineers,” says Mancisidor.

Their victory at Formula Student UK proves that when students are equipped with the right tools, mentorship, and mindset, they can compete and win at the highest level.

For the team, the FSB2025 was more than just a car. It was a vision brought to life through data, design, and determination — and a glimpse of the engineers shaping the future of mobility.

See how becoming an Ansys Student Team Partner can help your team design smarter and compete stronger.

Just for you. We have some additional resources you may enjoy.

“Being part of Formula Student Bizkaia has been a deeply rewarding experience. Ansys gave us the capability to simulate, test, and truly understand how our designs behave in the real world. It’s helped us grow not just as students but as future engineers.”

— Ibone Mancisidor, technical manager of Team Bizkaia

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.