想象一下,如果你是一支学生赛车团队的成员,你们既要负责设计和制造一辆能够征服崎岖地形的越野车,同时还要兼顾大学课程和实习。这正是工程专业学生每年在Baja SAE竞赛中面临的挑战,这是一项由美国汽车工程师协会(SAE)主办的越野学生赛车比赛。对于辛辛那提大学的Bearcats Baja赛车俱乐部而言,这项挑战不仅关乎造车,更是要重建团队停赛十余年间流失的知识与流程体系。

Ben Roberts是一名应届毕业生、Bearcats Baja赛车俱乐部前成员,他在关键时刻加入了这项工作。Roberts说道:“辛辛那提大学(UC)要求学生完成五次合作教育轮次(co-op rotations)或一次实习。在合作教育期间,我学习了如何使用计算机辅助设计(CAD),并且非常喜欢这样的工作。因此,我以CAD制图员的身份加入了Baja团队。”

作为2025届机械工程专业学生,Roberts在踏入机械设计领域后,快速掌握了CAD软件和有限元分析(FEA)的基础知识。他的职业生涯始于为团队进行基础CAD制图,后来逐渐负责主导仿真与分析工作,重新定义了团队造车的方式。由于团队之前的设计文件大多无法访问且已过时,他们几乎是从零开始进行重建。

Ben Roberts驾驶Bearcats Baja 赛车俱乐部赛车参加2025年Baja SAE大赛。

为了提升竞争力,团队采用了新思科技旗下Ansys工具来优化其设计流程。在Ansys学生团队合作伙伴关系的支持下,Bearcats Baja赛车俱乐部获得了专业级仿真软件和资源,这帮助该团队加速了重建进程,并更高效地优化其设计。从分析车架强度到确保组件可靠性,仿真已成为团队工作的基石。借助仿真工具,Bearcats不仅仅是在竞赛,更是在为更智能、更高效的设计新时代铺平道路。

了解Bearcats团队

Bearcats Baja赛车俱乐部由充满激情、积极进取的学生组成,他们将大量时间和精力投入到越野车设计和制造中,为Baja SAE竞赛做准备。这支由大约30名学生组成的团队,通过开展协作,将其愿景变为了现实。该团队由学生主导,各成员在四个子团队(悬架、车架、传动系统和商业)中担任特定角色和职责。其中,技术总监负责监督项目目标、筹措资金,并确保资源得到有效分配。

对高年级成员来说,该项目通常可以作为一项学术学习与实践应用相结合的“毕业综合项目(capstone)”。作为团队的计算机辅助工程(CAE)负责人,Roberts负责大部分设计与分析工作,解决了创建CAD模型和执行仿真等挑战。Roberts和他的团队成员不仅致力于打造一辆功能完备的赛车,还需分析故障和弱点,以确保赛车的每次迭代都优于上一次。在资源有限且成员经验水平参差不齐的情况下,该团队在很大程度上依靠协作和创造力来快速解决问题。

无论是通宵完善设计,还是争分夺秒备战比赛,Bearcats所展现出的投入与专注,充分体现了他们不仅执着于打造一款具有竞争力的赛车,而且还致力于在整个过程中共同提升彼此的技能。

Bearcats赛车在2025年Baja SAE耐力赛中的飞跃瞬间

仿真占据主导地位

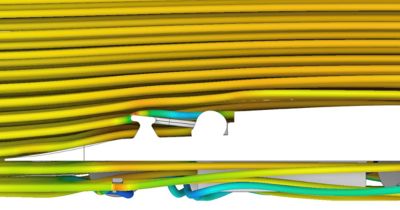

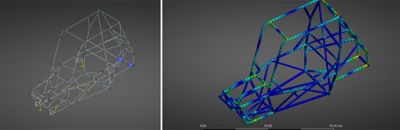

当Bearcats Baja赛车俱乐部开始采用仿真时,一切都发生了变化。利用Ansys Workbench仿真集成平台、Ansys Mechanical结构有限元分析软件和Ansys Discovery 3D产品仿真软件等Ansys工具,该团队可以虚拟运行测试,从而减少猜测工作和材料浪费。Roberts认为,整个流程始于为赛车车架和组件创建CAD模型——考虑到团队最初甚至没有完整的模型,这一步至关重要。Ansys软件解决方案使团队能够以之前难以想象的方式分析应力区域、位移和潜在故障点。

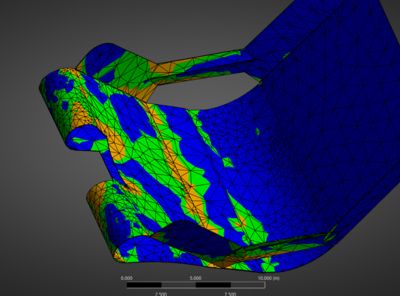

在Ansys Mechanical结构有限元分析软件中,对Bearcats Baja SAE赛车座椅进行6英尺坠落仿真

Roberts表示:“我使用Ansys Workbench平台运行仿真,这非常有帮助。我也没有任何Ansys使用经验,CAE或仿真经验几乎为零,仅依靠Ansys创新课程(Ansys Innovation Courses)和Ansys官网文档就快速上手了。”

Mechanical软件中的输出轴故障(左)和重新设计的输出轴仿真(右)

一个突出的改进体现在赛车车架上。通过运行仿真来评估其强度和刚度,该团队确定了可以在不影响性能的前提下安全减少材料的区域。最终,车架重量减轻25%,整车较前代车减轻了120磅。Ansys工具还在重新设计悬架和制动系统等其他组件方面发挥了重要作用,确保其能够满足严苛的竞赛需求。

Mechanical软件中的初始车架仿真

Ansys仿真的实时反馈和直观工作流程,有助于团队快速识别问题并做出调整。

Roberts称:“仿真的最大优势在于,虽然我们无法预判所有问题,但它能让我们更快地找出故障原因,并帮助更高效地规避设计缺陷。其本质上就是快速原型设计。”

Roberts和他的团队成员经常工作到深夜,在Discovery软件中更换部件并重新运行仿真,以确保项目进度。这种基于仿真的迭代方法,成为了提升效率和设计准确性的关键因素。

Roberts表示:“我能够在不到一周的时间内完成单个组件或小型装配体的仿真。”

Ansys创新课程助力成功

Roberts并未因不熟悉Ansys仿真而减缓步伐。他选择了学习Ansys创新课程——这些免费迷你课程涵盖了从流体与结构到电子与光子学等广泛物理领域和主题。

他表示:“我喜欢Ansys创新课程。它们非常直截了当,每次我都能准确找到所需内容。我几乎完全按照Baja SAE底盘分析和制动结构分析课程的指导操作,它们为我进一步学习高级功能奠定了坚实基础。”

步入正轨

展望未来,Bearcats团队专注于确保通过多年辛勤工作积累的知识不再流失。基于吸取的经验教训和使用的工具,该团队旨在为未来团队创建一个简化的流程。该团队已将文档记录作为其战略的关键组成部分,从而将仿真记录、设计迭代和测试结果传递给新成员。目标是让新生成员能够轻松无缝衔接上届团队的工作,减少每个赛季“重复造轮子”的时间。

Ansys工具始终是团队实现持续改进愿景的核心。团队在设计流程早期利用先进仿真,希望在不影响耐久性的同时,进一步优化组件并最大限度地提升效率。该团队还在探索让所有成员都能更便捷地使用仿真的方法,有望将仿真应用从核心成员普及至更多成员。因为,如果每个子团队将仿真融入其特定任务中,就可以在未来设计中释放更大的潜力。

通过专注于更明智的资源分配和营造协作文化,Bearcats Baja赛车俱乐部正在为未来更具竞争力的赛季奠定基础。该团队的发展历程证明,凭借合适的工具与团队合作,便可成就无限可能。

驶向未来

通过将Ansys工具融入流程中,Bearcats团队不仅打造出更卓越的赛车,更构建了更智能的设计方法。

Roberts表示:“整个流程结束时,我仿真的所有部件在比赛中都没有损坏,这是一个巨大的成功。设计与分析工作得到了回报,我们表现优异,在耐力赛中完成了33圈——这是我们迄今为止的最佳成绩。”

展望未来,Bearcats团队证明了,当学生将创造力与先进工具和实践经验相结合时,便能取得非凡的成就。他们的成果既体现了Baja SAE竞赛精神,也激励着其他团队不断突破学生工程所能达到的边界。

Bearcats团队在2025年Baja SAE大赛之前对赛车进行测试

通过Ansys学生团队合作伙伴关系,让团队设计进一步完善,并通过 Ansys创新课程实践,提高工程技能。

Advantage博客

Ansys Advantage博客(The Advantage Blog)由Ansys专家和其他技术专家撰写,让您随时了解Ansys如何为创新赋能,推动人类踏上伟大征程。