-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

July 29, 2019

What Is Design for Reliability (DfR)?

Engineers often talk about the importance of design for reliability (DfR) and the impact it has on a product’s overall efficiencies and success. So, let’s take a look at DfR fundamentals and how companies employ it to their best advantage.

What is DFR?

Essentially, DfR is a process that ensures a product, or system, performs a specified function within a given environment over the expected lifetime.

Design for reliability ensures that products and systems perform a specified function within a given environment for an expected lifecycle.

DfR often occurs at the design stage — before physical prototyping — and is often part of an overall design for excellence (DfX) strategy. But, as you’ll soon find out, the use of DfR can, and should, be expanded.

Why is DFR Critical?

The complexities of today’s technologies make DfR more significant — and valuable — than ever before. Some of these reasons include:

- Product differentiation: As electronic technologies reach maturity, there are fewer opportunities to set products apart from the competition through traditional metrics — like price and performance.

- Reliability assurance: Advanced circuitry, sophisticated power requirements, new components, new material technologies and less robust parts make ensuring reliability increasingly difficult.

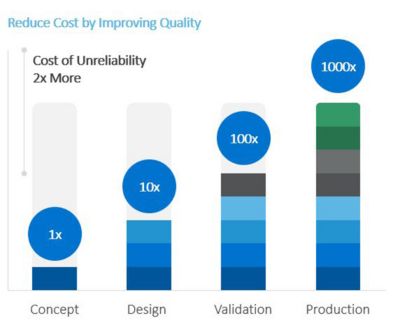

- Cost control: 70% of a project’s budget is allocated to design.

- Preserving profits: Products get to market earlier, preventing erosion of sales and market share.

When is DFR Used?

Most companies apply DfR at the design and development stage of a given project development cycle. However, this common practice comes too late in the development process.

Successful DfR requires the integration of product design and process planning into a cohesive, interactive activity known as concurrent engineering. Keep in mind, it’s less expensive to design for reliability than to test for reliability. When you are implementing reliability considerations in the concept feasibility stage, you are making all your decisions down the line with reliability in mind. Therefore, DfR is most effective in the concept feasibility stage.

Performing comprehensive design reviews during product development is a proven method to ensure a reliable product.

Who Should Be Involved with DFR?

With the goal of simultaneous design optimization, the typical engineering silos are counterproductive. Instead, concurrent engineering hinges on contributions from all essential project team members. As a result, those that need to be included in DfR include:

- Component engineers who manage the component library

- Systems engineers who set up the system constraints for an assembly

- Layout engineers who are assigned computer-aided design (CAD) responsibilities

- Manufacturing engineers who are responsible for design for manufacturability (DFM) and assembly/box connections

- Thermal engineers who develop boards based on power requirements

- Test engineers who establish environmental stress screening (ESS) and in-circuit test (ICT) parameters

- Reliability engineers who focus on statistical techniques and environmental testing — which typically become part of DfRs after the design phase

The processes you need to complete to ensure a product or

system is reliable is long, but it’s worth it. You can better understand and

rely on your products.

DFR Best Practices

Here are some DfR best practices that can apply to the development of nearly any project. These best practices also guide the process along.

- Set reliability goals based on survivability. This is often bound by confidence levels, such as 95% reliability with a 90% confidence level over 15 years.

- Avoid mean time to failure (MTTF) and mean time between failures (MTBF) because they do not measure reliability. Historically, MTBF has been calculated using the empirical prediction handbooks, which assume a constant failure rate that is not always correct.

Successful DfR requires the integration of product design and process

planning into a cohesive, interactive activity known

as concurrent engineering.

- Employ physics of failure (PoF) to acquire a deep understanding of how the desired lifetime and environment affect the design. This takes substantial effort, but there is valuable return in:

- Determining average and realistic worst-case scenarios

- Identifying all failure-inducing loads

- Temperature

- Humidity

- Corrosion

- Power cycling

- Electrical loads and noise

- Mechanical bending

- Random and harmonic vibration

- Shock

- Including all environments

- Manufacturing

- Transportation

- Storage

- Field

- Keep dimensions loose at this stage. A large number of hardware mistakes are driven by arbitrary size constraints.

Ansys Sherlock automated design analysis software augments DfR by providing reliability insights as early in the product development process as possible. This optimizes product reliability, development time and cost savings.

To learn, in detail, how to bring DfR into the development process, watch the webinar: Introduction to Reliability Physics Analysis.