Ansys材料和化学加工解决方案

加速过程工业的数字化转型

Ansys仿真解决方案可降低运营成本,提高当前的竞争力,并推动未来先进材料系统的创新。

通过仿真加速创新和降低成本

Ansys仿真解决方案使材料和化学加工企业能够显著提高整体设备效率(OEE)、产能和原材料利用率,从而提高运营效率并降低成本。

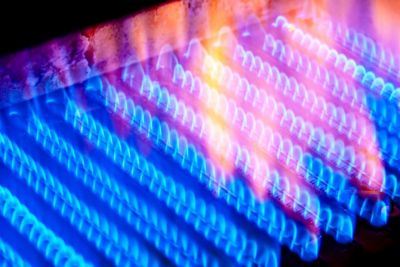

从设备和加工、化学和炼化、到玻璃、聚合物和金属制造,Ansys仿真解决方案可加速未来先进材料系统的创新,同时帮助我们的客户节约能源,最大限度地减少环境影响,满足更高的监管标准并简化产品开发。

-

材料加工

-

环境和水处理

-

化学加工

优化最困难的材料加工挑战

即使是最复杂的资源密集型流程,工程仿真也能实现优化,最大限度地减少其环境影响,同时管理整个企业的材料信息。

改善污染控制和水处理

仿真可以提高污染控制系统的性能,改善空气和饮用水的质量,并减少废水排放对环境的影响。

在不降低安全性的情况下推动化学加工的创新

仿真可实现化学加工流程的创新和优化,同时确保安全运营,降低能耗并改善排放控制。

应用

仿真正在推动材料和化学加工行业的创新。Ansys解决方案涵盖从化学加工的详细物理分析到系统级仿真。

通过优化产品和流程性能,仿真可以在提高产量的同时消除浪费,从而产生可量化的业务影响。

视频标题

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

材料信息商业案例

与数字化转型的其它领域相比,材料信息管理软件已相对落后。

材料信息对于工程企业的生产力、创新、成本和风险至关重要。

在仿真和材料数据管理的推动下,第四次工业革命已然开启。企业级材料信息是数字化加工行业转型的下一个前沿领域。

在推动第四次工业革命的数字化转型中,制造业的大多数领域经历了巨大的变革。计算机辅助方法目前已成为大多数产品工程领域的标准实践。尽管材料信息在产品设计和制造中发挥着关键作用(通常价值数百万美元),但它尚未被纳入到数字化转型的版图之中。

Ansys证明了为什么材料信息管理应被视为核心的工程技术,以及它如何能够使制造商大获裨益。优化的材料信息可帮助应对设计流程每一步中的关键挑战,从减轻产品重量、延长产品使用寿命到减少质保索赔,不一而足。系统化的材料信息方法可为各行业的制造企业提供帮助。

视频标题

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。