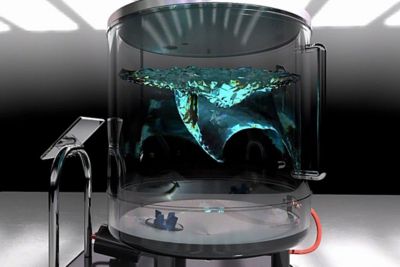

Increase Product Uniformity

Ansys Simulation tools accurately predict final mixture compositions. Make adjustments prior to prototyping to meet your quality targets.

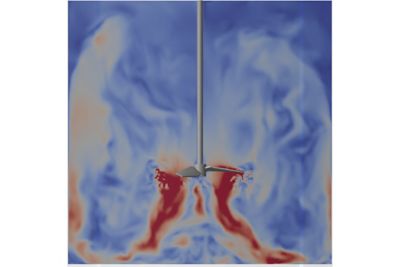

Reduce Operating Costs

Analyze your mixing method to optimize productivity, enabling you to produce more efficiently and save time.

Product Performance

With simulation, you can predict systems performance and assess the mixing process. Validate design work faster with Ansys.

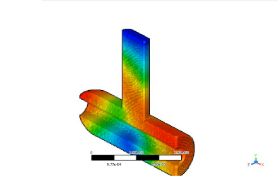

Enhance Vessel Performance

With simulation, you gain better insight to how your vessel reacts to mixing and predict how it handles pressure and thermal loads.