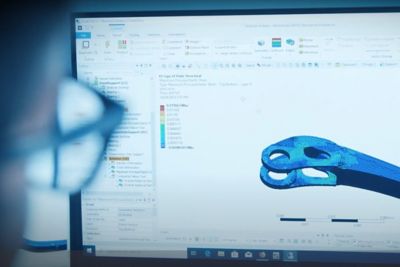

Get Best-in-Class Simulation Software at Startup Pricing

Dreaming big and making those dreams a reality is a huge undertaking for early-stage startup organizations. We understand. And we’re committed to helping you solve your engineering challenges with affordable software, making the impossible possible.