When it comes to powertrain performance, sometimes oil and air just don’t mix. Discover how engineers use simulation to prevent oil tank sloshing that can abruptly end a race.

Andreas Roos, Head of BMW M Motorsport, had big aspirations for this season for the BMW M Hybrid V8 prototypes, anticipating optimizations in all areas of development.

“The goal is to intensify the development of the BMW M Hybrid V8 in collaboration with the specialists at the teams and at BMW M Motorsport,” Roos said in a press release late last year.

So far, Roos’ goals have, in part, been achieved in the first four IMSA Weathertech Sportscar Championship races of the season, where BMW M Motorsport managed to start in all pole positions. BMW M Motorsport also celebrated a number of strong podium finishes at both IMSA and the FIA World Endurance Championship (FIA WEC).

The car driven to those finishes, BMW M Motorsport’s LMDh racer, is an exotic racecar engineered for extreme speed, endurance, and full-throated performance. Its optimization process begins with time behind the wheel, yielding driver feedback that ultimately returns to the engineering department. Powertrain optimization is high up on the list, as every aspect of performance must be systematically scrutinized.

Let’s chat with Holger Laumanns, mechanical design engineer in powertrain at BMW M Motorsport. He talks about his work for BMW M Motorsport, both past and present, and how it’s impacting vehicle development across the organization, including the BMW M Hybrid V8.

Marco Wittmann displayed consistently strong performances in the No. 11 Schaeffler BMW M4 GT3 EVO at Oschersleben.

What vehicles are you working on currently?

Holger Laumanns: Right now, we are mainly working on the LMDh and GT3 powertrains. We do 3D design, FEM (finite element method) calculation and also CFD (computational fluid dynamics) simulation in different areas. The BMW M Hybrid V8, for example, runs on a V-shaped four-stroke twin-turbo with a regulated output of approximately 640 horsepower at approximately 650 Nm (Newton meter) of torque.

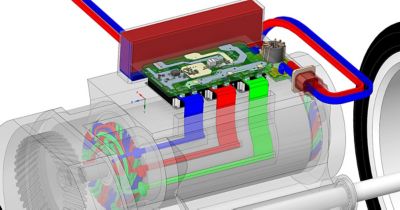

Regulations specify that LMDh cars have, in addition to a combustion engine, an electric motor. One of my tasks at the beginning of this project was to simulate the sloshing behavior of the oil tank with Ansys Fluent fluid simulation software. With the results we were able to optimize the geometry of the oil tank.

BMW M Motorsport is benefiting from Ansys simulation software during development, testing, and validation of engine performance across global motorsport programs.

Why is oil tank optimization important?

Laumanns: As we have a dry sump engine there is no oil reservoir at the bottom of the engine. The oil reservoir is the oil tank, and it's located in front of the engine. All the oil, which is dropping down inside the engine, is collected in the sump. It’s more or less the lower cover of the crankcase. As the volume of the sump is very limited, we have to pump the oil very quickly into the oil tank.

But there is not only oil in the crankcase. We also have blow-by gases in the crankcase that are entering the crankcase from the combustion chamber.

In this instance, we have to ensure that no oil leaves the tank and no air is sucked into the lubrication system. That means the intake port of the main lubrication pump, which is located at the bottom of the tank, is always covered with oil. If air enters the oil pump we reduce the lubrication and cooling of the engine components. This will not lead directly into a catastrophic engine failure if this happens once, but over time we increase tear and wear and it could become a problem.

How do g-forces impact oil tank sloshing during a race?

Laumanns: When the race car is heading towards a corner and brakes for example, the oil inside the tank is pushed to the front. In our case away from the inlet port of the oil pump. Depending on the g-force, the surface of the liquid could be angled very steep. If the oil level is too low or the g-force is too high the inlet-port will be in contact with air. To avoid this situation, we integrated baffles and chambers.

On the other side we also have to take care about the ventilation on top of the swirl pot. The air outlet is connected to a catch tank. The function of this catch tank is to collect any oil drops that exit the tank. This catch tank is controlled by a scrutineering oil level sensor. If the catch tank reaches a certain level during the race we have to empty it. That could cost us quite a bit of time.

Simulation of the swirl pot, or upper area of the oil tank of the BMW M Hybrid V8 engine.

How did the oil tank optimization come together using Ansys Fluent software?

Laumanns: So this is really interesting, I think. At that time, when we started the sloshing simulation, we just had the powertrain data. The actual vehicle did not exist. So, there was no car and of course no track data (g-forces) available. In the absence of a physical car, my colleague did the layout capturing the basic functions. Then he prepared a model to put into the simulation environment.

At this point I took over. As the LMDh car was new there was no track data available, so we looked into the track data of similar cars. In general, we looked for the most extreme conditions of different racetracks in relation to g-forces. We then took several sequences of different racetracks and “stitched” them together until we had a g-force/acceleration profile of 10-20 seconds. That was enough to evaluate the behavior of the oil tank.

The simulation of a complete lap takes too long at this stage. So we did a few iterations (may be 10) until we had a working concept. We then took the best concept and did the sloshing simulation again but with oil flow and airflow (blow-by gases).

Are you using simulation to solve other challenges as well?

Laumanns: Yes, we use it also for other disciplines like simulation of the cooling system, and also for parts of the exhaust system like wastegate control or battery cooling simulations. I think my first simulation with Ansys Fluent software was a transient simulation of the wastegate control/pneumatic lines. It worked quite well and we were able to improve the response time of the wastegates.

Together, BMW M Motorsport and Ansys are pushing the limits of the BMW M 4 GT3 EVO on and off the racetrack.

What are the benefits of using Ansys software to achieve your engineering goals?

Laumanns: So, I imagine the biggest one is time. If we don’t have simulation, we have to do lengthy hardware testing and of course that takes time. And that’s why we use simulation. We can do more testing loops, which means more iterations before testing real or final parts.

During the design process, we simulate all systems and components of the powertrain with Ansys software where needed. Also, after dyno-testing or track testing, we still do simulations or check the results of the simulations. It’s a lot of back-and-forth. If we see something wrong, we change it, then start over again with the information we get from the dyno or track.

If we take the oil tank as an example, without simulation we would need — for each design — a real part to test it on a shaker. The lead time for a rapid prototyping tank could be a week. Then you need to test it. That all adds up. With simulation, we can evaluate a design easily within a day.

In general, the accuracy is quite good. It matches our test results and also the data from the track. It's not 100%, but let’s say it's 99%, so it's good enough.

To us, the level of support provided by the Ansys technical team is really beneficial. We made the switch from a competitive product to Ansys because of the level of support they provide. When we had a challenge, Ansys stepped up to deliver an efficient way of doing things in a timely manner, and also shared a dedicated workshop explaining the process.

We’d like to thank Holger Laumanns for sharing his insights on powertrain development in motorsport. If you enjoyed this interview, be sure to check out Simulation Helps NASCAR Assess the Impact of SAFER Barriers, where the vice president of safety at NASCAR shares how simulation supports safety technology development on the track.

“With simulation we can evaluate a design easily within a day.”

— Holger Laumanns, mechanical design engineer in powertrain, BMW M Motorsport

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.