ANSYS BLOG

August 26, 2022

How Simulation Drives the Top Automotive Trends: Electrification

The debate over whether automotive is going electric or not is over. All major original equipment manufacturers (OEMS) have made the announcement that they are going fully electric within a few years. And globally, all have set very aggressive targets to meet these visionary goals. This is reflected in the commitment of suppliers to make an investment in electrification while combustion engines are very much a relevant part of their profits.

As a result of this movement toward electrification, the automotive market is undergoing tremendous disruption. The big three are still Ford, General Motors, and Stellantis; however, with the shift to electrification, other names have surfaced. Lucid Motors, Rivian, and Tesla are just some of the emerging companies who, through their growing influence in the industry, are challenging and changing the way we think about electric vehicle (EV) technology.

Powering Through EV Design Challenges

All OEMs are facing big challenges with their design cycle, as the cycle for an EV is much shorter than before. Today, many EV startups are releasing vehicles in 18 months, or 12 months for a new year release cycle. For OEMs still operating on a more traditional cycle, everything needs to speed up. To catch up, they face new design, retooling, personnel, and production challenges as they shift gears from internal combustion engine (ICE) to EV manufacturing.

Of all the factors that play a role in electrification, the biggest one is cost. How do you reduce the cost to produce a vehicle and speed up the development cycle while remaining ahead of the competition? At the same time, how do you make the product more reliable? This leads us to Ansys simulation software solutions. It’s safe to say virtually everyone in the automotive space believes that digital engineering and digital innovation are the way to go. From specifications to systems validation, Ansys helps mobility innovators such as BMW, Porsche Motorsport, and Volkswagen evolve their electrification strategies.

“Digital engineering through simulation helps companies innovate faster, better, and cheaper — from initial design to simulation-driven product development,” says Dr. Zed Tang, Solution Architect for Electrification at Ansys. “And, almost everyone is focused on using more simulation to help drive EV designs of the future.”

With EV Efficiency, Every Fraction of a Percent Counts

Within this new environment, OEMs and top-tier automotive suppliers face new challenges in pushing the boundaries of engineering design and the boundaries of their engineers. Thinking about a traditional gas engine again, they are not that efficient — maybe 40% thermal efficiency. With an ICE, improving your efficiency by one-tenth of a percent is significant to extending vehicle range. But at the end of the day, you could also just increase fuel tank capacity by one more gallon to achieve a similar result.

This is not the case for electric vehicles, because of the energy density of the battery pack, which has a per-unit weight or per-unit volume that is much less than fuel. Compared to liquid-based petroleum fuels, EV batteries store less energy, and require additional modules to compete with ICE driving ranges. In this scenario, companies also have to push the boundaries of EV design to reach maximum efficiency, because every bit of energy wasted can lead to a big disadvantage in the current market.

So, going back to our previous ICE example, an engineer can’t simply just say: “Hey, I can increase range by making my fuel tank a little bit bigger, and I will solve the problem.” If you add one or more battery modules in your vehicle, you will add significantly more weight. For your EV, you have to adjust the size of your motor and your electronics because you will need more cooling; so it’s more than just a battery pack. Suddenly, your vehicle is heavier, and the battery is consumed more quickly by the weight of all the added elements.

For this reason, engineers are doing whatever they can to push the boundary of their design. If peak efficiency is 98%, everybody is trying to work out a way to develop something that is 98.1%.

“So, what does it mean to engineers working in the field?” asks Tang. “You can’t prototype enough or test enough to determine what that extra one-tenth of a percent is anymore. You have to dig deep, and how do you do that? You use simulation, because with simulation you can find out all of this. With some tweaks here and there with added automation and optimization, you can see results virtually and visually in a way that can help you understand much better how to extract that additional 0.1%.

The move toward automotive electrification encompasses much more than a shift from internal combustion to battery power. Infrastructure, maintenance, and a host of other variables must be considered.

Empowering Automotive Engineers Through Simulation

We've just discussed how to achieve efficiency from the engineering side, and how, enabled by simulation, engineers can push design boundaries to meet these challenges. There’s also a boundary being pushed from the organizational side to help engineers be more efficient. Currently the automotive industry is facing a big challenge from other industries and other locations looking for expertise. There’s a workforce shortage everywhere, but even more so on the electrification side. It’s more than just Detroit now — it’s the West Coast, Texas, Colorado, Washington, where you have all kinds of startups looking for experts in electrification.

If automakers can’t hire enough engineers, they need to think of ways to empower their engineers to be more efficient and effective. How they do that is by building automation into their workflows and processes. They can also increase the level of collaboration between different engineers and different teams from different disciplines, which is what Ansys has been doing for years in the area of electrification. Ansys has expanded its multiphysics capabilities beyond automotive structure to meet challenges involving electromagnetics, controls, functional safety, reliability, materials intelligence, and more.

“Ansys provides not only the multiphysics simulation capabilities, but the streamlined workflows, design automation and optimization, high-performance computing (HPC), and cloud-enabled solutions to assist engineering teams,” says Tang “The learning curve is short. You don’t need to spend days or weeks learning how to push a button. It’s what Ansys has been doing on the development side and the application side to help their automotive customers work through their transition to electrification.”

Charging Ahead With Ansys

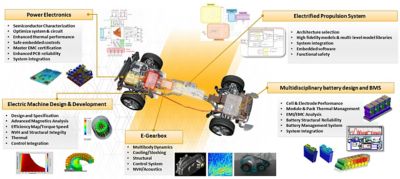

Meeting the extraordinary design challenges posed by electrification demands extraordinary solutions. Electric mobility leaders are benefiting from Ansys simulation solutions in electrified powertrain system simulation, battery management systems, electromagnetic interference/compatibility (EMI/EMC), and electric motors to accelerate and innovate the design process, including but not limited to:

- Ansys Mechanical, a structural finite element analysis (FEA) software for addressing performance and system complexities, from noise, vibration, and harshness (NVH), to battery structures, power electronic assemblies, and thermo-mechanical strain.

- Ansys Fluent, a computational fluid dynamics (CFD) simulation solution enabling the robust design and improved performance of electric powertrains, from batteries to electric motor cooling to external aerodynamics.

- Ansys Maxwell, a low-frequency electromagnetic field simulation solver for electric machines that captures the nonlinear, transient motion of mechanical components and their effects on drive circuit and control system design.

- Ansys Motor-CAD, an electric motor design, analysis, and verification tool that can deliver a complete workflow from concept to detailed electromagnetics, thermal, and mechanical analyses of the motor.

- Ansys SCADE Suite, a model-based development environment for embedded software design and verification critical to electrified powertrain integration, battery management system, and vehicle electrical system applications.

- Ansys Twin Builder, an open solution that enables engineers to build digital-based virtual replicas of electrified systems and monitor the behavior of their related components throughout the product life cycle.

These products are all part of our broader portfolio for automotive electrification.

Visit our Automotive Webinar Series page to sign up for on-demand presentations on how Ansys engineering simulation solutions can advance your EV development

Stay tuned for our next blog, where we will discuss challenges in autonomous vehicle (AV) technology and highlight a few Ansys products that help our customers meet these challenges.