In January, Forbes delivered its global automotive outlook for the year based on the current state of the industry. As we move into 2026, those dynamics are not only continuing but accelerating.

Automakers are leaning on hybridization as a bridge to sustainable mobility while electric vehicle (EV) growth stabilizes amid persistent infrastructure and affordability challenges. At the same time, increased demands for software-defined vehicles (SDVs) and advanced driver-assistance systems (ADAS) are colliding with the rapid rise of artificial intelligence, further reshaping how vehicles are designed, developed, and experienced.

Remaining competitive in 2026 and beyond will depend on how effectively manufacturers and suppliers embrace AI and digital engineering to manage growing complexity and tightened development cycles to deliver vehicles that are smarter, safer, and more efficient.

So, how will they contextualize this success? The answer lies in identifying solutions that lead to faster decision-making and innovation through enhanced collaboration. Yet for many original equipment manufacturers (OEMs) and suppliers, the integration and flow of decisions across teams remains a challenge, exposing significant operational risks.

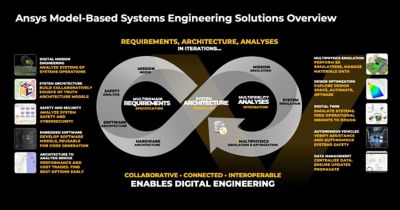

In this environment, model-based systems engineering (MBSE) emerges as a critical methodology in managing high levels of automotive complexity. It enables engineers to work collaboratively to navigate requirements and confidently validate next-generation vehicle designs early, with greater efficiency.

“If you have good automotive system engineers, in the past they would sit around a table. Maybe it's a virtual table,” says Scott Ragon, principal product manager at Ansys, part of Synopsys. “They could exchange documents and do a good job of design. But as the complexity level of vehicle design goes up and as the number of people involved in the process increases, that strategy doesn't work anymore. The traditional way of doing systems engineering breaks down. MBSE is a more structured, organized alternative to doing systems engineering that delivers exponentially better results.”

Despite the potential benefits of MBSE, however, adoption across much of the automotive industry requires a significant cultural shift. A model-driven approach must be embraced, and traditional workflows need to conform to current challenges. MBSE often calls for integration across supply chains using proprietary tools and methods, which can create a seemingly formidable transition for many. But it doesn't have to be that way.

The Role of MBSE in Automotive

MBSE is a methodology that focuses on using digital systems and engineering domain models as the primary means of exchanging information, feedback, and requirements, as opposed to document-centric systems engineering. It involves capturing, communicating, coordinating, and maintaining digital models of a given system throughout its life cycle.

MBSE can play a pivotal role in automotive innovation. It offers a structured, model-driven approach that can successfully manage the complexity of the interconnected systems and advanced software defining today’s vehicle systems. MBSE also addresses the gaps often associated with traditional automotive engineering by centralizing the system design process to ensure traceability from requirements to implementation.

If MBSE were a superpower, it would give automotive engineers the ability to create a source of truth for the system architecture embodied in one shared system architecture model. Universal access to a single-source model ensures that every stakeholder has access to consistent, updated, accurate information regardless of the vehicle component, subsystem, or systems being worked on. It also reduces the risk of inconsistencies and redundancies across teams that result from a more siloed engineering approach.

Simulation plays a pivotal role in automotive MBSE as it helps engineers ensure that they are meeting key requirements, facilitates understanding among all stakeholders regarding product behavior, and helps them address complex problems. In the context of EVs and SDVs, MBSE connects design requirements to the appropriate simulation workflows to speed up verification and validation.

For instance, during EV powertrain development, MBSE helps engineers analyze trade-offs among battery size, motor specifications, and component weight to optimize for range, cost, and performance while satisfying all requirements.

“All design decisions in electric powertrain come down to performance relative to cost,” says Tushar Sambharam, senior principal application engineer at Ansys. “When you're facing design decisions in EV development, you're making a choice, and that choice always has implications. What cell electrochemistry, battery cooling system, or motor specifications should I choose? And how will these choices impact other choices and my objectives for performance — like vehicle range — and cost? These types of understandings can easily be developed through an MBSE workflow.”

MBSE and the Future of SDVs

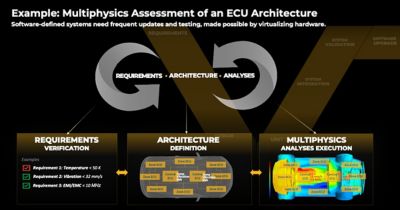

During SDV development, MBSE facilitates the defining and refining of electrical and electronic (E/E) architectures in consideration of dynamic software updates and advanced vehicle functionalities. Front-loading much of an SDV’s functionality onto a software-driven framework poses its own set of challenges during development. It’s a task compounded by dynamic updates that will be pushed out to many different systems over the life of the vehicle.

MBSE provides a foundational framework necessary to design, validate, and maintain the complex E/E architectures supporting SDVs. Its value is in sorting through platforms encompassing numerous components, including electronic control units, sensors, actuators, and wiring supporting ADASs, infotainment, autonomous, and electrified systems.

Leveraging MBSE to define zonal E/E architectures, for instance, helps streamline electronic control unit (ECU) placement by grouping functions within specific zones of the vehicle and connecting them to a central high-performance computer (HPC). It enables engineers to map these zones, define the flow of data, and validate vehicle architecture against automotive manufacturing requirements for safety, cost, and performance.

MBSE offers an iterative approach to continuous integration/continuous deployment (CI/CD) workflows and practices, automating and enhancing the software development life cycle with a focus on system quality and reliability. Taking this approach can positively impact any number of things, from integrating code changes to releasing software.

“When engineers are changing software dynamically, further verification and validation follow,” says Sambharam. “Directly or not, you still cannot breach the thresholds of the constraints around the workings of a vehicle. For example, let’s say I updated the software and my battery is overheating. That's not the kind of issue you can expect in a vehicle — that's a safety-critical issue. What CI/CD says is, every time you develop something, you validate it through an MBSE approach to make sure it's working fine before moving into deployment.”

Specifically, the continuous integration of software updates into an MBSE framework enables engineers to validate changes against system requirements while ensuring compatibility with existing vehicle hardware — without compromising safety or performance. This includes the continuous deployment of changes automatically to production after successful testing.

Ansys Delivers Essential MBSE Technology Stacks

What makes MBSE so valuable for OEMs and tier suppliers is its usefulness in delivering on historically crucial priorities related to cost, time to market, and late-stage defects. MBSE provides a structured approach to testing and requirement verification that empowers engineers to identify and resolve design issues early in the development cycle, preventing costly rework and recalls later in production.

To this end, many Ansys tools support primary MBSE objectives in automotive engineering during vehicle development:

- A cloud-native SysML v2 platform, the Ansys System Architecture Modeler (SAM) capability provides a foundation for building and managing complex system architectures in a virtual environment. Acting as a central collaborative repository for system design, it ensures traceability and helps teams to define relationships between components to streamline development.

- Ansys ModelCenter MBSE software connects system architecture models to simulation environments, enabling model-based requirement verification. It empowers engineers to create and automate multitool workflows and optimize product designs.

- Ansys medini analyze system-oriented safety analysis software supports functional safety analysis and compliance with safety standards like ISO 26262, ensuring that safety-critical requirements are identified and verified early in the design process.

- The Ansys Scade One model-based embedded software development solution facilitates the development of embedded software via certified code generation that seamlessly integrates with the overall system architecture. This tool plays a critical role in creating control software for EVs and SDVs.

Ansys’ open ecosystem bridges the gaps between the tools used to design these systems. It provides a structured, efficient, and integrated way of partnering with teams, suppliers, and customers to deliver differentiated vehicle technology.

Specifically, the SAM capability can be leveraged to catch design flaws early in a design cycle. The tool’s powerful real-time collaboration features promote interaction among all engineers involved in the design process, enabling OEMs and suppliers to seamlessly share models and collaborate simultaneously on system designs. This is an important advantage, as a single vehicle often incorporates components from multiple suppliers.

“With the advent of SysML V2, it will be possible for our customers to share models between different vendors’ tools,” says Ragon. “So, you will be able to create a model in the Ansys tool, and if you know someone down the supply chain is using a competitive tool, you can give them your model and they can import it into their tool. SysML v2 therefore promises to fundamentally alter the proprietary and vendor-locked nature of SysML v1.”

Future Aspirations for MBSE in Automotive

Today, MBSE is poised to transform how vehicles are designed, developed, and maintained. It can help engineers manage complexity and achieve early validation through innovative workflows to better address EV and SDV development challenges. Ansys offers aspirational software frameworks in a collection of tools and solvers that can facilitate MBSE across the automotive industry.

The complexity of SDVs requires a focus on safety in design. Check out Achieving Secure Software and Seamless Upgrades in Software-Defined Vehicles to discover how model-based tools enhance integration, streamline development, ensure compliance, and protect against cyberthreats.

Make sure to catch Redefining Automotive Safety, Performance, and Optimization With MBSE for insight on how an MBSE approach to SDV development helps automakers identify early performance and cost trade-offs.

Just for you. We have some additional resources you may enjoy.

“MBSE is a more structured, organized alternative to doing systems engineering that delivers exponentially better results.”

— Scott Ragon, principal product manager, Ansys, part of Synopsys

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.