-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

ANSYS BLOG

July 21, 2020

Top 5 Features in Ansys Mechanical in 2020 R2

Our latest release, Ansys 2020 R2, continues the tradition of constantly improving our simulation solutions in response to your requests and our goals to lead the world in engineering simulation. In Ansys Mechanical, we have made significant enhancements in the areas of intelligent, advanced nonlinear structural solvers with a focus on automotive, reliable electronics and overall improved workflows. Here we highlight the top 5 new features that can help you solve your engineering challenges faster and easier.

1. Contact Detection Technique

Simulating assemblies can be challenging. Snap fits, interference and changes in loading cause parts to come into contact with each other in various ways. Ansys Mechanical features updates in its solver that increase simulation convergence success with a reduced number of iterations. These updates allow for faster and more robust solving of challenging contact problems.

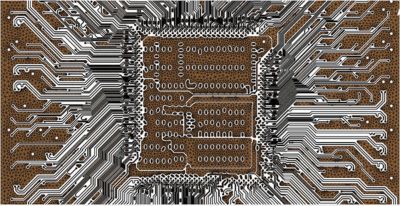

2. Electronics Reliability and Modeling

With the increasing electrification and digitalization of every part of our society, electronics reliability is critical. To help with this, we have made it possible for you to open several electronic CAD file types directly in Ansys Mechanical and control the degree of detail in components of the model. By simplifying the representation of complicated components that are not pertinent to your analysis, you can reduce setup time, start solving sooner and achieve quicker solve times.

We have made the pre-processing of electronics even easier by incorporating the reinforcements workflow from Ansys Sherlock into Ansys Mechanical. This will help you to model layout and via structures at every level efficiently and accurately, including die metal layers, substrates and printed circuit boards. Sherlock now also features trace reinforcements, enabling more accurate electronic models and meshes that consist almost entirely of hexahedral (brick) elements.

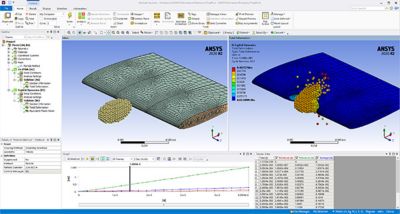

The reinforcements workflow from Ansys Sherlock has been

incorporated into Ansys Mechanical for more accurate electronic models.

3. Smooth Particle Hydrodynamics (SPH) in the Ansys Mechanical UI

With our acquisition of LSTC, we have introduced LS-DYNA solver capabilities for simulating high-speed impacts, blasts or explosions in Ansys Mechanical. Our latest integration of Smooth Particle Hydrodynamics (SPH), which enables you to control the elasticity and other properties of simulated colliding particles, is now available with LS-DYNA and Mechanical. This will make your analysis of the effects of collisions easier and faster, and will enable you to perform advanced fluid–structure interaction simulations.

Ansys Mechanical now has more integration of LS-DYNA with

smooth particle hydrodynamics (SPH) for explicit analyses.

4. Cycle Jumping to Reduce Solve Times for Thermo-Mechanical Fatigue

Cyclic-loading (fatigue) analysis is important in a variety of industries such as automotive, aerospace, nuclear power, chemical, electronics and others where the lifing analysis of components is an essential part of the design procedure.

Performing a fatigue life evaluation for every load cycle of a machine or component is too time-consuming, even when using simulation. The new cycle jump feature in Mechanical reduces solve times for thermo-mechanical fatigue problems where plastic deformation accumulates over repeating load cycles. In a cycle jumping scenario, simulation results from previous cycles are used to update the fatigue state of the material after a larger number of cycles. Substituting the results of a few cycles for many (i.e. cycle jumping) dramatically reduces solve times.

5. New Parameter Fitting for Plasticity Models

Understanding material properties is key for engineers who want to minimize thermo-mechanical fatigue in gas turbines, engines and electronics, just to name a few applications. To better fit empirical test data to material models, we have added a new parameter fitting capability to improve matching for plasticity models used in these applications. We have also added artificial intelligence (AI) technology to simulations that use the Chaboche material model. The AI assumes isothermal conditions and considers only a small strain framework for modeling material behavior, which accelerates the simulations.

These are just the top 5 of many enhancements to Ansys Mechanical in the latest release. View this on-demand webinar to learn about more of the Ansys Mechanical features in 2020 R2.