-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Every space mission contains two critical requirements:

- Safely reaching the intended orbital altitude

- Safely operating throughout the full projected mission timeline

Fulfilling these requirements proves especially tricky when designing optical payloads for space. Optical payloads, which include elements such as telescopes and cameras, aren’t known for their durability. However, when used in space missions, these payloads must be able to survive a rocket launch, achieve continuous mission success in orbit, and everything in between.

Accomplishing this means designing optical payloads that can withstand harsh mechanical loads, handle wide temperature ranges, function over large distances, and more, all while abiding by tight weight restraints and not interfering with a spacecraft's temperature or balance. Moreover, everything must be attained while achieving the highest possible performance to ensure mission success.

Striking this balance isn’t easy, but that’s where innovators in the space optics field shine.

As an example, take the NarSha project, a pioneering Korean initiative for detecting and tracking methane emissions on Earth from space. Through this project, researchers hope to achieve high-resolution monitoring of global methane point sources in near real time.

Designing lenses for the NarSha project

To achieve this goal, the NarSha project relies on a consortium consisting of Nara Space Technology, Seoul National University, the Korea Astronomy and Space Science Institute, and Poland-based Scanway Space, a company developing advanced optical instruments for space.

Scanway’s role in this consortium is to design and supply the critical advanced optical payloads for the Korea Methane Monitoring Microsatellite (K3M). This microsatellite will demonstrate the project’s technology and serve as a baseline for NarSha’s planned constellation of 12 or more satellites.

When it launches in 2026, K3M will rely on two complementary optical systems that Scanway developed:

- A primary hyperspectral imager that operates in the short-wave infrared (SWIR) range and can achieve a ground sample distance of ~30 meters at a 500 km altitude

- A visible/near-infrared (VIS/NIR) camera that enables on-site discrimination and improved data fidelity

“Together, these instruments offer wide swath coverage of more than 10 km, enabling detailed mapping of methane emissions at local level scales,” says Michał Zięba, CTO Scanway S.A. “This combination of hyperspectral and VIS/NIR imaging, installed on a compact, agile platform, exemplifies how Scanway’s payloads empower tracking and quantifying greenhouse gas emissions with high spatial and temporal resolution. Ultimately, the resulting data will bolster climate change mitigation strategies by providing accurate, timely insights into methane leaks — from industrial facilities to landfills to anywhere in the world.”

This is just one example of how Scanway is developing complete optoelectronic solutions for applications ranging from Earth observation and space situational awareness (SSA) to lunar exploration.

Taking a Closer Look at Scanway

Within the competitive field of space optics, Scanway stands apart from the crowd "by combining flight-proven technology, deep in-house expertise, and a uniquely flexible approach to mission design,” says Zięba.

Relying on the expertise of its small-but-mighty 50-person team, Scanway focuses on developing specialized, high-performance telescopes, camera systems, and software for satellite manufacturers to integrate into existing designs.

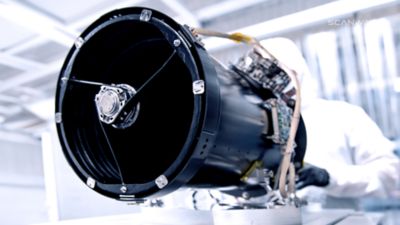

A Scanway optical payload

Scanway’s optical instruments are designed to be adaptable for use in a wide range of designs. Its modular products:

- Are compact and lightweight, ensuring that they can be used in nano- and microsatellite missions

- Are powerful enough to deliver sub-meter ground sample distance (GSD) from low Earth orbit (LEO)

- Offer configurations that cover a broad spectral range, including VIS, NIR, SWIR, multispectral, and hyperspectral

- Provide end-to-end capabilities that range from concept, design, and testing (using Scanway’s own cleanroom-equipped assembly, integration, and test facility) to integration and post-launch support

- Are powered by an engineering team with expertise spanning optics, electronics, software, and systems integration

Scanway uses its modular product designs to ensure that every payload it creates is optimized and customized to meet each customer’s unique mission requirements.

“Whether providing high-resolution Earth imagery, enabling advanced space situational awareness, or supporting exploratory missions beyond Earth, Scanway’s payloads deliver cutting-edge optical performance in compact, mission-ready packages — pushing the boundaries of what small satellites can achieve,” says Zięba.

No matter the mission, customers with a variety of goals can use Scanway’s flagship optical systems, the Scanway Optical Payload (SOP) and Scanway Camera System (SCS). These systems have achieved Technology Readiness Level 9, which means that they are operational instruments already performing successfully in orbit.

But how did Scanway achieve such success and design their adaptable and modular optical systems? This is where simulation comes in.

Narrowing Our Lens: Advancing Space Optoelectronics With Simulation Software

Designing optical systems for space is no easy feat. Scanway needs to develop products that can withstand demanding space conditions — such as extreme temperatures, radiation, and shocks — while also providing optimized imaging and meeting all standards and requirements. As a result, this “requires us to meticulously plan and simulate individual operational scenarios of the whole spacecraft,” says Zięba.

To tackle these challenges, Scanway partnered with MESco, an Elite Channel Partner of Ansys, part of Synopsys, and took part in the Ansys Startup Program. These collaborations help “us quickly overcome challenges and make full use of advanced simulation tools,” says Michał Łyczkowski, Lead Mechanical Engineer at Scanway S.A. “Thanks to their responsiveness and expertise, we can focus on innovation rather than troubleshooting.”

Through these collaborations, Scanway was able to use Ansys Zemax OpticStudio optical system design and analysis software (including the STAR capability), Ansys Mechanical structural finite element analysis software, and Ansys Thermal Desktop thermal-centric modeling software to:

- Design complex optical systems that consist of multiple lenses and mirrors

- Perform advanced structural analyses and validation

- Conduct accurate stray light and mitigation simulations

- Generate thermal analyses of the complex thermal cycles that are typical of Earth’s orbit as well as within the design itself, with an emphasis on the impact of stable and transient temperature conditions on mechanical tolerancing

- Analyze optical performance as a function of thermal and mechanical loads

- Optimize its structural, thermal, and optical designs with a focus on manufacturability to build designs that achieve mission success (such as providing sufficient imaging quality) and the best possible performance in operational conditions

- Support manufacturing, assembly, and collimation

“Ansys simulation solutions were key to ensuring payload survival and performance,” says Łyczkowski. “We relied on structural simulations to verify that the instrument could withstand rocket launch loads and on thermal analyses to optimize its design for stable performance across the expected temperature range. This gave us confidence that the payload would operate reliably in orbit.”

As a specific example of Scanway’s use of simulation solutions, consider the flexibility and modularity of its products. While this is undeniably a great benefit, it is also challenging for the company to efficiently address each customer's unique requirements. It can prove resource-intensive to ensure that every design is optimized for a specific customer’s platform, launch, and operational conditions.

Here, Scanway finds Ansys simulation solutions invaluable. Ansys tools provide multiphysics analysis that combines mechanical, thermal, and optical studies, streamlining the optimization process and saving essential time when tailoring designs to a variety of use cases.

“The most crucial aspect of Ansys software for us is the compatibility of different tools across the whole portfolio,” says Łyczkowski. “From optical simulations through mechanical strength calculations to thermal simulations, Ansys software allows us to focus on the task at hand without worrying about the compatibility and availability of specific solvers and editing tools.”

To ensure that its telescopes can survive throughout an entire space mission, Scanway must study radiative heat transfer, thermal conduction, exposure to sunlight, and mechanical resonance, then discover how each of these aspects impacts optical performance. Through advanced multiphysics simulation analyses, Scanway can accurately determine if its design will withstand operational scenarios in orbit earlier in the design process. This saves resources when designing critical products, such as Scanway’s high-resolution imaging telescopes, which have tight tolerances and must be analyzed comprehensively.

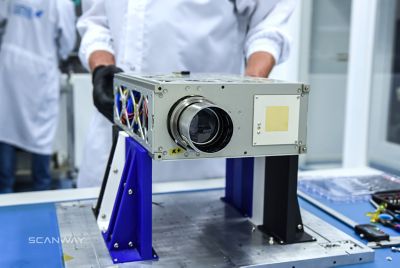

Designing an optical payload for space solutions at Scanway

Additionally, Scanway, like its cohorts in the space industry, is unable to test its prototypes in the real operating environment of space. Not only is testing in space time-intensive and costly, but only fully verified products can be deployed into space.

To combat these limitations, Scanway conducts laboratory tests that it correlates with simulation data. In doing so, Scanway ensures that its simulations have a high level of correlation with the real-world working conditions and performance of its optical payloads, thereby saving both time and money.

The Benefits of Ansys Simulation Solutions for Space Optics

Simulation software is an important part of Scanway’s toolbelt, providing concrete benefits that enable the company to continue to innovate in the space industry.

“By using Ansys software, we significantly reduced the number of physical prototypes and iterations, which shortened our development timeline and lowered costs,” says Łyczkowski. “In practice, this allowed us to cut testing cycles by around 30% and accelerate the design-validation loop. The result is faster delivery of flight-ready instruments without compromising quality.”

A Scanway optoelectronic product

In addition, the use of Ansys simulation solutions, along with the support from MESco, enabled Scanway to:

- Better optimize its payload’s technical parameters while mitigating risk

- Develop and deliver more than 10 optical instruments for use in space missions, with over 10 more in active development

- Gain a competitive advantage in the global space-tech market

What’s Next for Scanway?

Scanway’s progress is not slowing down anytime soon. The company is already considering its next application of simulation software: using Ansys optiSLang process integration and design optimization software to support early design trade-offs.

“By automating sensitivity studies and optimization, we can quickly evaluate a wide range of design parameters and identify the most promising concepts in opto-mechanical design before entering detailed development, including any structural and thermal influence on optical performance,” says Łyczkowski. “This will allow us to accelerate decision-making, reduce risks, and ensure that our instruments are optimized from the very beginning.”

Scanway is also participating in new and exciting partnerships and projects, including two products that have been shortlisted for the Small Lunar Missions program, an initiative of the European Space Agency (ESA). A new partnership with Intuitive Machines, which will involve providing an optical instrument to map the lunar surface, is also promising for future development and collaboration.

Curious about other advancements in space? Learn all about the latest in space cameras and space innovation.

Just for you. We have some additional resources you may enjoy.

“By using Ansys software, we significantly reduced the number of physical prototypes and iterations, which shortened our development timeline and lowered costs. In practice, this allowed us to cut testing cycles by around 30% and accelerate the design-validation loop. The result is faster delivery of flight-ready instruments without compromising quality.”

— Michał Łyczkowski, Lead Mechanical Engineer at Scanway S.A

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.