-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

See how Perellion uses simulation to build custom machines and solve industrial equipment challenges with manufacturing and logistics solutions.

If you’re part of the aerospace culture in the Pacific Northwest, you might be familiar with Perellion. The Washington-based automation startup is a member of the Pacific Northwest Aerospace Alliance (PNAA) and drives innovation in aerospace and defense (A&D) machinery. A notable recent project involved creating a remotely adjustable center of gravity (CG) lifting device for a multibillion-dollar space program. However, A&D machinery is just one area of expertise of this versatile company, which develops custom automated equipment and tools across industries, from aerospace, energy, and robotics to manufacturing and logistics. Additionally, the company offers engineering consulting services and custom solutions built to customer specification.

Founded in 2020, Perellion is dedicated to creating technical solutions through precision, expertise, and innovation. Striving for excellence in every project, this includes in-depth analysis powered by multiphysics simulation tools from Ansys, part of Synopsys.

With access to the software initially through the Ansys Startup Program, Perellion continues to integrate Ansys solutions with support from Ozen Engineering Inc., an Ansys Elite Channel Partner. As a result, Perellion increases engineering accuracy and performs iterative design virtually, optimizing product development, safety, and reliability.

Solving Problems With Simulation

“It was never a question of what tool we needed,” says Cody Brown, president, co-founder, and controls engineer at Perellion. “Ansys (simulation software) is the tool we’ve always used.”

Brown and his team of nearly 50 engineers, including mechanical engineers Tyler Rourke and Kenny Howard, combine decades of engineering and simulation experience. Rourke worked closely with Ozen Engineering to integrate Ansys software at Perellion.

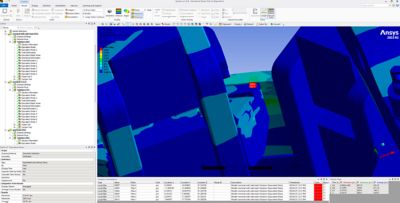

Howard and team recently used Ansys simulation software to design a sophisticated, remotely adjustable CG lifting device that was proof load tested to 180,000 lbs. It will soon transport more than $100 million in space flight hardware.

“With the large quantity of lift permutations, driven by the differing weights and positions of the flight hardware, Ansys software was the logical tool to handle analyzing all the varied load cases,” Howard says. “Achieving factors of safety of 4 to yield and 5 to ultimate within the strict lifting device mass and dimensional requirements meant there was a lot of iterative optimization of the structure, and in some instances the use of high-strength exotic materials. Having Ansys (software) available to speed up the design cycle iterations was critical to the success of this challenging project.”

For thermal and structural analyses, including stress and fatigue, the team used Ansys Mechanical structural finite element analysis (FEA) software and Ansys LS-DYNA nonlinear dynamics structural simulation software.

Cody Brown, president, co-founder, and controls engineer at Perellion

Tyler Rourke, mechanical engineer at Perellion

Kenny Howard, mechanical engineer at Perellion

Perellion engineers perform thermal and structural analyses, including stress and fatigue, in Ansys Mechanical structural finite element analysis (FEA) software.

The tools were also used to design custom machinery with safety-critical components for a logistics application for a Fortune 500 company. To tackle this design, Ozen Engineering supported Perellion with refined fatigue analysis using Ansys tools, including model setup with boundary conditions. The part is now in production and deployed on a couple of hundred machines, with plans to scale into the thousands.

“There are some components on this machine so safety critical that if they fail, it could mean loss of life or limb for humans working on or around the machine, and these machines are subject to millions and millions of cycles in their design life,” Brown says.

Perellion builds custom machinery across industries, develops custom solutions built to customer specifications, and offers engineering consulting services.

Perfecting Process Development With Multiphysics

In another example of Perellion’s versatility, the team built a custom machine for an energy company to manufacture 1.5-meter-diameter quartz cylinders that melt quartz sand into glass.

The machine is a massive plasma arc furnace equipped with robots and cooling systems. Cooling components are certainly needed, considering the robotic system uses positioning axes to join three carbon electrodes and strike an arc of 10,000 amps (A) at 480 volts (V). For reference, arc flashes can exceed 35,000 degrees Fahrenheit, almost four times hotter than the Sun’s surface.

With nearly 5 megawatts (MW) of convective and radiant energy emanating from the furnace, Brown’s team used Mechanical software’s steady-state thermal module to analyze the thermal load’s impact. In addition, the team designed the systems to withstand the large heat flux loads for extended periods, as the cylinder doesn’t simply cool to ambient temperature. It’s a controlled process over several days.

“I’m very proud of what we produced because most automation builders would run away from this screaming, like, ‘Absolutely not, who wants to work on a project where you’re handling the Sun?’” Brown says. “Yet for us, that’s exactly the sort of problems we want to be working on — very hard, high-engineering content, deep analysis, and ultimately pushing the bounds of materials and physics.”

He emphasizes the importance of process development, explaining that once a machine is complete, it still takes time — sometimes up to a year — to get it working optimally in production.

“That’s the second half which, I think, interests way less folks in the space we operate,” he says. “And yet that’s where we provide a lot of value in that we want to work on it until it’s done, it’s working, and it’s in production.”

Brown’s team also developed the machine’s software interface and control system.

Starting Up Success With Emerging Technologies

Digital engineering with Ansys simulation software is not an option for Perellion engineers — it’s a necessity.

In addition to Mechanical software and LS-DYNA software, the team used Ansys Discovery 3D product simulation software and Ansys high-performance computing (HPC) solutions.

“It’s a necessary tool set for us to complete our job,” says Howard. “As much as we’d love to do everything on hand calcs and actually work through (problems) to make sure everything’s fine, you can’t use hand calcs for everything, so we needed to have Ansys software in the team.”

Brown says simulation has been most valuable for optimization, as demonstrated during the remotely adjustable CG lifting device design.

“We were absolutely running up against system mass limits, so we used Ansys simulation extensively to pull mass out of the system while maintaining very high factors of safety,” he says.

Brown explores Perellion’s facility with co-founder Reese Allen, the company’s vice president.

Brown also credits the Ansys Startup Program for helping Perellion flourish in its formative years.

“We’re a privately funded, bootstrapped engineering firm,” Brown says. “We didn’t start with $10 million from venture capital (VC) money or anything, and over the last 4-and-a-half years, we have made enormous investments in our enterprise resource planning (ERP), product life cycle management (PLM), computer-aided design (CAD) software, and all the software we use to write the control systems for our machines. The Ansys Startup Program has helped our business grow substantially. Money in the early days is tough to come by.”

What’s next for the startup?

“At the end of the day, we design and build machines and tools, but we want those machines and tools to be working on problems for tomorrow,” he says.

Ansys is dedicated to advancing industrial processes and equipment with innovative solutions. To learn how Ansys can support your early-to-mid-stage business, visit the Ansys Startup Program.

Just for you. We have some additional resources you may enjoy.

“The Ansys Startup Program has helped our business grow substantially.”

— Cody Brown, president, co-founder, and controls engineer, Perellion

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.