ANSYS BLOG

August 2, 2023

Amogy Promotes Ammonia Power with Ansys Startup Program Support

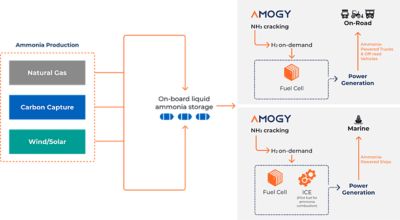

Could ammonia be a real game changer in the race to net-zero? Amogy, a sustainable energy startup, believes it’s an important clean energy source for heavy industries, including maritime and power generation. Citing its unique properties, the company sees an immense opportunity. Today, its ammonia-based, emission-free, high energy-density power solutions are well positioned to shape a more sustainable future.

Founded in 2020 by four Massachusetts Institute of Technology doctoral alumni with a shared vision, Amogy aims to accelerate the global journey to net-zero with its ammonia-to-power technology. They’ve secured the support of Amazon’s Climate Pledge Fund, as well as Temasek, SK Innovation, Aramco Ventures, Mitsubishi Corporation, and Mitsubishi Heavy Industries to accomplish this.

Specifically, Amogy is building a novel, portable, carbon-free energy system that uses ammonia as renewable fuel. The technology has many potential applications, including shipping, power generation, hydrogen generation, and more. So far, this scalable zero-emissions energy system has been demonstrated in a 5 kW drone, 100 kW mid-sized tractor, and 300 kW semi-trucks — thanks, in part, to Ansys simulation software.

Amogy’s ammonia-powered 100 kW tractor

Amogy’s ammonia-powered 300 kW semi-truck

“Simulation is one of the critical enablers to scaling our technology to meet this objective,” says Matt Montgomery, Combustion and Simulation Manager at Amogy. “Because we work on a very large scale, analyzing product designs and testing small changes within a simulation environment up front helps us move through product development cycles faster. Using Ansys software within a digitized workflow increases our engineering productivity to realize our vision of a decarbonized transportation system much faster.”

In ‘Startup Mode’ with Ansys

Right from the start, simulation has been an important part of Amogy’s development strategy. Early on, Amogy discovered Ansys Fluent’s advanced capabilities and began using it as a more viable alternative to meet its simulation needs for model upgrades.

“Ammonia will be pivotal in the integration of hydrogen into green transportation solutions of the future. This carbon-free hydrogen carrier is more energy dense than compressed or liquefied hydrogen, and more than 5X denser than a conventional lithium-ion battery. With help from the Ansys Startup Program, we’re realizing all of these advantages in an ammonia-based, sustainable technology to deliver a lower-cost, higher-power fuel alternative that’s suitable and more sustainable for power-demanding heavy transportation applications."

— Young Suk Jo, CTO at Amogy

Of course, in “startup mode,” new product development is Amogy’s main goal. The ability to support prototyping and design decisions with high-fidelity simulation is extremely important, as the data resulting from analysis will ultimately inform new prototypes that lead to future products. Comparing simulation software, Amogy needed to identify a solution that enabled quick, efficient simulation run times at a comfortable price point.

Cue the Ansys Startup Program, which is specifically geared toward early-stage startups with limited funding and revenue at their disposal. The program provides full access to Ansys multiphysics simulation software and high-performance computing (HPC) resources at an affordable price to give startups the support they need in a competitive landscape.

“The Startup Program enabled us to test a variety of Ansys products and implement them into our workflow at a time when we could not afford the commercial license pricing,” says Montgomery. “As a result, we were able to leverage Ansys resources during the initial growth of the company, which helped us get to the point where we could afford the commercial licenses ourselves.”

Better Tools Yield Bigger Insights

Making the switch to Ansys software helps Amogy address several key challenges. First, Ansys multiphysics tools enable its development team to study the effects of different design features in a digital environment without requiring a physical prototype, accelerating the prototyping process to reach design decisions faster. These same tools also help them zero in on expected product temperature profiles that would otherwise be hard to measure. They also offer a more in-depth look at the physical phenomena Amogy technology relies on to understand various factors such as the physical properties of its materials.

Amogy relies mainly on Fluent and Ansys Mechanical. Both solutions have become an integral part of an extended workflow that begins with the analysis of a design concept before the design is sent out for fabrication.

Initial activity can range from a single simulation to examine some aspect of a flow field to a week-long optimization study on a specific design feature. Within Amogy, designers provide the simulation team with a computer-aided design (CAD) model. From there, the team meshes the design in Fluent Meshing and generates case files in Fluent.

Results formed from these activities are then used to update certain features in the design, and the process repeats until the design is ready to go out for fabrication.

The science behind Amogy’s technology

Shorter Runtimes Save Almost an Entire Day’s Work

Ansys solutions were used to improve product design through the study of combustion, surface and volumetric chemical reactions, and heat transfer. This analysis involved anywhere from 1 million to 20 million elements. Simulations were enabled by cloud HPC clusters and local desktops for large and small simulations, respectively, to improve simulation run times.

“Before Ansys, we had a simulation of roughly 1 to 2 million cells running on about 300 cores, which took almost 24 hours to converge,” says Christopher Stanczak, Mechanical Engineer at Amogy. “Using Ansys software, the same simulation could be completed in a few hours on our local machine. Since we run our large simulations on HPC clusters on the cloud, the time savings results in cost savings, as short runtimes mean less time paying for the cluster.”

Learn more about the Ansys Startup Program.