-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

The NASA X-59 Quesst recently soared into the sky for its maiden voyage. This unique aircraft was carefully designed using computational fluid dynamics (CFD) to mute the thunderous double-boom of traditional supersonic aircraft.

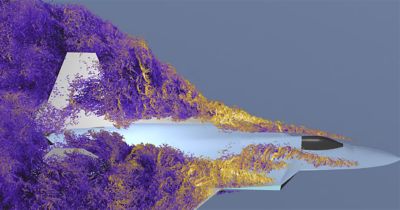

NASA’s X-59 quiet, purpose-built supersonic aircraft will validate simulation results that predict a dramatically quiet sonic thump. In the Ansys simulation above, streamlines are colored by velocity magnitude. The exhaust plume is a volumetric CFD temperature data field. Temperatures are rendered with a black body color scale, in which higher temperatures are more emissive and opaque.

Popular movies often depict futuristic aircraft reaching speeds far beyond expectation on their first flight. A stirring soundtrack builds suspense as a heroic test pilot ignores orders to stop and impulsively pushes the throttles to the max. The control room cheers as the craft streaks across the horizon.

In real life, the NASA control room still cheers, and test pilots are definitely heroic. But NASA test pilots are not impulsive — in fact, they are much more careful than most cinema depictions. The X-59’s first flight is significant, but it purposefully did not break the sound barrier. Test pilots follow meticulous incremental protocols to safely validate aircraft performance, and data from each flight is reviewed before the next slightly more aggressive maneuver is planned. Eventually, aircraft performance is validated throughout the entire flight envelope, and the aircraft receives a safety certificate.

The first flight is one of many carefully planned steps that began years ago to ensure that the X-59 can safely carry out its mission: Introduce the American public to quiet supersonic travel.

Ensuring Safety With Simulation

One of the incremental tests NASA pilots work up to are high-lift maneuvers. In emergency situations, pilots must be able to retain control at high angles of attack up to and exceeding the critical angle of attack. NASA test pilots will carefully approach this point, in which the aircraft stalls and begins to fall from the sky. Loss of lift occurs when airflow above the wing becomes turbulent and streamlines dramatically separate from the wing’s upper surface. For many aircraft, the stall critical angle of attack is in the 15-to-18-degree range.

Thankfully, advanced CFD simulation tools can help pilots and engineers understand exactly the conditions in which stalls begin. In fact, there is an entire community of simulation leaders who meet regularly to share new information on achieving flight with a high angle of attack. Better understanding and control in this flight regime is critical for all aircraft to take off and land safely.

Modeling High Pitch Rates With the Ansys Fluent GPU Solver

Ansys has a tradition of simulating aircraft at extreme limits and is a longtime participant in NASA’s High-Lift Prediction Workshops (HLPWs). Ansys was at the first meeting in 2010 and has participated for over 15 years. (You can view the 2024 focus group summary here.) At these meetings, representatives from industry, academia, and government meet to discuss lift and drag predictions on increasingly complex aircraft geometries. The goal is to collaborate on best practices, but there is also friendly competition to see who most accurately matches previously unpublished wind tunnel test data. CFD codes become faster and more accurate every year, and better tools produce safer aircraft — including the X-59.

The updated HLPW workflow from 2025 was applied to an X-59 aircraft geometry Ansys has studied for the past six years. In the first step, the Fluent meshing capability created a rapid octree mesh around the c608 variant of the X-59. This high-quality hexahedral mesh was refined at the aircraft boundary and contained 172 million elements. The meshing tool generated the mesh in only 11 minutes using 192 CPU cores. The minimum orthogonal quality of the mesh was above 0.3, which is considered very good.

The mesh was read by the Fluent GPU solver to produce high-fidelity flow results. The pressure-based segregated solver included an ideal gas air material and included the energy equation to accurately describe engine intake and exhaust flow rates and temperatures. The freestream velocity around the aircraft was set to Mach 0.2. Turbulence was described by the wall-modeled large eddy simulation (WMLES), which allows excellent resolution of flow separation above the wing. The X-59 was oriented in progressively steeper angles of attack up to 20 degrees using a sliding mesh approach. For this test, an airshow-worthy pitch rate of 20 degrees per second was implemented. After pitch-up, the aircraft was held at 20 degrees to enable flow to fully develop.

The animation below shows flow behavior as the X-59 rapidly pitches upward. The isosurfaces of the normalized q-criterion at a value of 50,000 are colored by velocity magnitude. Q-criterion surfaces help identify areas of high turbulence and illustrate vortex structures. The q-criterion isosurfaces would normally cover the entire aircraft body, but they have been clipped to focus on the largest vortex structures. Note how the canards just ahead of the main wings redirect airflow along the wing root. The exhaust plume may look like an “afterburner,” but it actually represents a volumetric CFD temperature field. Higher temperatures are depicted as more yellow-white in color, emit more light to the scene, and are more opaque.

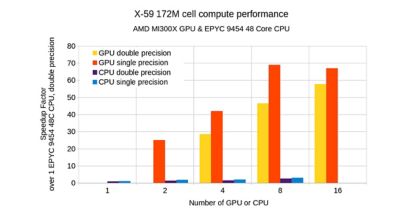

The Fluent GPU solver simulation ran on AMD Instinct MI300X GPUs. Peak throughput was at single precision on eight GPUs requiring only 0.27 seconds per iteration. Five seconds of flow time were simulated in just 3.7 hours on the wall clock. Although this case ran well with single precision, double precision is recommended for most sliding mesh simulations. With twice as many decimal places, this case scaled to 16 AMD MI300X GPUS. Results were still ready in less than 4.4 hours.

These premium AMD MI300X GPUs are 22X faster than the equally top-quality AMD EPYC 9454 48-core CPUs. It is safe to say that GPU computing is changing the way engineers do simulation — just a year or two ago, simulations like these would have taken several weeks and required thousands of CPU cores.

Using High-Fidelity CFD To Meet Design Goals

Highly accurate simulation data is critical for new aircraft such as the X-59. Performance goals like quieting sonic booms are important, but they are useless if the aircraft is unstable in flight. Ansys tools like Fluent fluid simulation software help engineers quickly create reliable, robust designs that fulfill their missions.

Simulation results have already been used to ensure the X-59 has good handling characteristics despite its long nose. They influenced the placement of the canards to ensure stability and have even been incorporated into an X-59 flight simulator. Test pilots already have a very good idea of how the aircraft will handle as they push it toward the most extreme flight conditions. Once NASA has verified handling and safety, the X-59 will fly over U.S. cities to demonstrate the quiet supersonic technology. These tests will confirm what we in the simulation community already know: An aircraft traveling faster than a speeding bullet will make the unremarkable sound of a car door closing in a parking lot. Over the next few years, the American people will decide how they feel about the adoption of overland supersonic flight based on this new quiet technology. The benefits speak for themselves — for example, a 6.5-hour flight from Boston to Los Angeles would take only 3.25 hours.

Learn more about Fluent software, or try out the X-59 in the NASA X-plane simulator.

If you like the images and animations created for this blog, consider downloading a 4k version for your desktop background:

Just for you. We have some additional resources you may enjoy.

If you’re ready to take your CFD simulations to the next level, make sure to join us at Supercomputing 2025 in St. Louis from Nov. 16 to 21.

Disclaimer: The simulation video and images were created from a geometry Ansys redrew from the public domain model. NASA was not involved in their creation.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.