-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

ANSYS ADVANTAGE MAGAZINE

May 2022

It is often said that a hydraulic valve is the “heart” of the hydraulic system. If there is instability in the system, the issue is rarely the pump, the cylinder, or the hoses. The valve is at the center, so designing an exceptionally performing valve is critical. At Parker Hannifin’s Hydraulic Valve Division, simulation-driven design is integral to the product development process, and simulation tools from Ansys are used as one of the key elements to building better valves.

The mechanical failures that contributed to the massive Deepwater Horizon oil spill in 2010 focused the world’s attention on component reliability, including valves intended to prevent such disasters. Clearly, reliability improvements were needed. While the choke-and-kill systems and blowout preventers used on the rig were based on tried-and-true hydraulic technologies, they simply were not good enough.

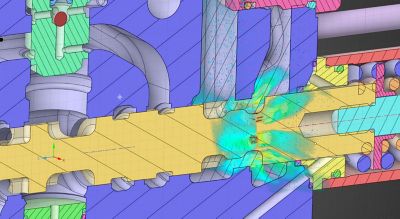

Hydraulic valve flow force optimization study

For engineering organizations around the globe, the failure of these systems raised questions that needed answers. How can valves intended for use in extreme, dynamic environments be designed to operate more reliably? How can an organization validate that new designs will actually deliver the increased reliability required without many years of prototyping and testing? Behind these questions lie serious design and quality assurance challenges, but equally important are the practical challenges that go hand in hand. How can we reduce the amount of time it takes to build and test prototypes of any new design? How can we minimize the number of design/refinement cycles a more reliable valve will require? And how can we ensure that newer, safer valve designs are affordable in a competitive marketplace?

To assist in addressing some of these questions, Parker engineers rely on pre-validating design concepts through the use of simulation tools across multiphysics domain. Ansys is included as a partner for providing those tools.

A Platform Primed for Performance

While Elyria, Ohio, is far from any offshore oil rig, it is where Parker works its magic. Here, engineers develop and modify all types of valve designs for customers in industrial markets (including undersea oil and gas operations) and mobile markets — such as companies building heavy equipment for construction, agriculture, forestry, and other industries.

While the requirements of companies seeking solutions for problems that may occur a mile beneath the sea might seem very different from those of companies seeking solutions for a vehicle lifting heavy loads in a logging or mining operation, the underlying valve technologies informing these solutions are not always that different. Parker has a number of hydraulic valve platforms that can be customized and modified to meet a wide range of customer requirements. Simulation plays a decisive role in determining how best to meet those requirements.

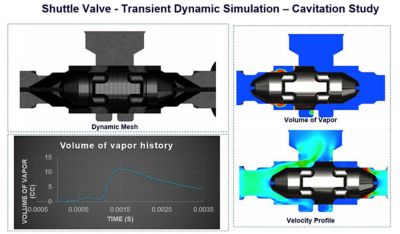

In some cases, a clean sheet design approach is utilized. In others, computer-aided design (CAD) models of Parker’s stock valves are imported into mechanical simulation tools, such as Ansys Mechanical, where the team can model optimal ways to incorporate specific features or functionality that a customer might require. Modified designs can then be stress- and performance-tested via mechanical simulation to analyze the physical aspects of the valve and its parts, or by using computational fluid dynamics (CFD) simulation tools, such as Ansys Fluent, which analyzes the fluid performance of the designs to determine how each design will operate under different conditions. Based on the results of each analysis, engineers can make refinements to a design in order to optimize valve performance or reliability, and arrive at an ideal combination of materials to balance strength and cost, and more.

Subsea valve cavitation study

Particularly advantageous to Parker is the fact that engineers can design and refine a valve to meet a customer’s needs without having to take time to build and test prototypes of each design iteration. Parker’s simulation engineers have used simulation tools in conjunction with validation testing for years, thereby building confidence in “first time right” accuracy of the data presented by the simulation tools. Since the old-school process of “design-prototype-test-repeat” could take four to six months to complete — and might have to be completed three, four, or more times — the “design-simulate-refine-repeat-prototype” model of development yields an optimized design in far less time (and often at a far lower cost). Not only will a customer get a prototype faster, but that prototype is far better designed and engineered because simulation has enabled multiple “design-test-refine” iterations before the prototype is manufactured. Only when engineers have a design candidate that optimally delivers the features and functionality that a customer has specified do they construct an actual prototype of the valve.

Better Valves Lead to Better Business Relationships

Parker’s evolving use of simulation tools has increased its ability to solve ever more complex problems, and this has led Parker to new customers and opportunities. By using simulation to study cavitation erosion in a high-pressure undersea setting, for example, Parker’s engineers developed a solution that would dramatically reduce the instabilities inherent in commonly used sub-sea systems caused by cavitation erosion — thereby overcoming a problem that had plagued oil and gas companies for years. New doors opened as a result.

Similarly, by using simulation to study flow forces on a valve used in construction equipment lifting heavy loads, Parker’s engineers developed simulation-driven optimization techniques to eliminate valve instability induced by flow forces, which translated to a much smoother, higher-performing vehicle that enhanced an operator’s productivity and safety. By gaining greater insight into the effect of flow forces on different components of the valve and running simulations to understand what effects a change to that part’s geometry might have, Parker is able to build valves that have proven to be far more stable, reliable, and efficient than its competitors.

And simulation is spreading within Parker. While a specialist team of simulation engineers runs more complex simulations on powerful workstations or a high-performance computing (HPC) system in the cloud, other engineers within Parker are using various simulation tools for simpler problems. A hidden benefit of using many of the same tools across the corporation is the ability to share knowledge, making it easier to share best practices and methods.

In the end, this democratization of simulation delivers benefits that accrue to everyone involved. Engineers at Parker’s Hydraulic Valve Division can develop better products faster and at a lower cost, and Parker’s customers gain well-engineered hydraulic valves and systems that are tuned to their specifications and perform as expected.

“Parker’s evolving use of simulation tools has increased its ability to solve ever more complex problems, and this has led Parker to new customers and opportunities.”

Additional Resources:

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.