Case Study

-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

“Manual calculations from first principles often require many assumptions and simplifications to solve the problem. Issues arise when the problem is complex and cannot be simplified without heavily impacting the validity of the results. This is where an efficient and user-friendly FEA software becomes important. Ansys Mechanical software provided the best overall experience out of all the FEA software we have used and enabled us to solve these complex problems with confidence.”

— Uri Naidoo

Junior Mechanical Engineer / Trotech

Trotech Improves Storage Tank Platform Design With Efficient and Interoperable FEA Software

Real-world loading scenarios can be difficult to simulate. Trotech strives to maintain the highest standards of quality and safety throughout the engineering, procurement, and construction (EPC) of above-ground bulk storage tanks and associated supportive equipment, including platforms.

With support from Qfinsoft (Pty) Ltd, an Ansys Channel Partner, Trotech integrated efficient finite element analysis (FEA) using multiphysics simulation solutions from Ansys, part of Synopsys.

These solutions revealed stress and deflection problems, clarified load paths, and informed platform design upgrades. In addition, the software integrated seamlessly with Trotech’s existing computer-aided design (CAD) software.

Challenges

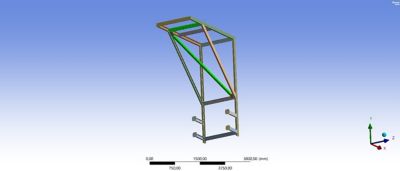

Designing a storage tank platform with structural components that influence and rely on one another presents significant challenges. Analyzing each component separately under specific load conditions doesn’t accurately represent its behavior in practical use. For this reason, Trotech required an intuitive and adaptive FEA tool that could integrate imported CAD models to visualize and verify the platform’s overall structural stability.

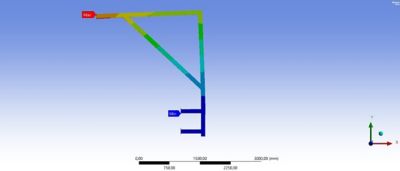

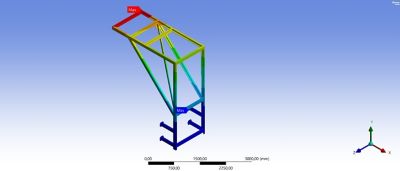

Ansys Mechanical structural analysis showed excessive deflection and stress when loading the platform to simulate the effect of a person standing on the outermost point of the cantilever.

Trotech engineers used Mechanical software to simulate the structure’s path of motion during loading and placed additional structural components as needed.

Trotech engineers tested the new gauge platform design under the same conditions as the previous version and confirmed that the deflection and stress results met the acceptable range.

Engineering Solutions

Managing structural behavior and performance under high-load conditions presents distinctive challenges that require thoughtful analysis and specialized tools. To address these issues, Trotech used Ansys Mechanical software to perform detailed FEA simulations while integrating CAD imports, focusing on deflections, von Mises stresses — which show yield or deformation — and overall structural stability. As a result, Trotech identified critical areas for improvement, ensuring its storage tank platform design meets safety requirements and customer satisfaction.

- Ansys Mechanical software’s intuitive interface and mesh options made FEA faster and more efficient.

- The software’s interoperability supported easy integration with Trotech’s existing CAD software.

- Simulation results highlighted weaknesses in design, including stress and deflection.

- Visualizing the platform’s movement under load clarified how forces traveled through it.

- Guided by insights from FEA and simulation, Trotech reinforced the platform with additional structural components.

For over 30 years, Trotech has specialized in the engineering, procurement, and construc-tion (EPC) of bulk storage tank solutions for the petrochemical, liquefied natural gas (LNG), ammonia, and sustainable fuel sectors.

Trotech integrates finite element analysis (FEA) and simulation solutions from Ansys, part of Synopsys, to optimize storage tank platform design, ensuring compliance with safety requirements and customer satisfaction.

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.