Case Study

-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

“Our intended scope was to use existing input data to predict when engine parts would fail. The idea was to avoid using full-scale simulations and instead use a low-computation-load reduced-order model (ROM) to obtain quick results. With that goal in mind, by combining the capabilities of multiphysics solvers and reduced-order modeling, it became possible to make predictions based on the current state.”

— Motomi Mizugai

Assistant Chief Engineer, Development Center, Komatsu Ltd.

Komatsu Predicts Engine Life of Construction and Mining Equipment with Simulation and Reduced-Order Modeling

Komatsu engineers planned to use existing data, including temperature data from an internal satellite system, to run simulations and predict engine part failure. However, Komatsu preferred to use ROMs instead of full-scale simulations to accelerate predictions and simulation run time during operation.

With multiphysics simulation solutions from Ansys, part of Synopsys, including reduced-order modeling, Komatsu reduced model complexity, accelerated runtimes, and verified data through structural, fluid, and thermal analyses.

As a result, Komatsu developed a method to predict engine failure more quickly and efficiently than expected.

Komatsu is a leading global manufacturer of construction, mining, forestry, and industrial heavy equipment. Source: Adobe Stock Images. This image is for illustrative purposes only and does not depict the actual product or component.

Challenges

Komatsu builds essential industrial and construction equipment that power critical operations around the world. As such, unexpected equipment failure and downtime can have a direct impact on customers’ bottom lines, causing costly delays and lost productivity.

Komatsu engineers did not have an efficient method for predictive maintenance or forecasting engine life. Full-scale simulations can be computationally expensive and time-consuming. In addition, traditional thermal fatigue analysis requires calculation data of real thermal conditions.

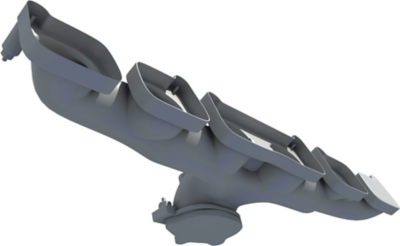

Renderings of an exhaust manifold. This image is for illustrative purposes only and does not depict the actual product or component.

Engineering Solutions

- Komatsu used computational fluid dynamics (CFD) capabilities in Ansys Fluent software to perform a steady-flow analysis of the exhaust gas heat flow inside the exhaust manifold and obtain data for heat transfer analysis.

- Using the CFD data, Komatsu performed a heat transfer analysis in Ansys Mechanical software to calculate the structure’s temperature and complete a thermal strain analysis and strain calculation.

- Next, finite element analysis (FEA) results from Mechanical software were analyzed in Ansys nCode Design Life software to evaluate thermomechanical fatigue (TMF) and determine the fatigue to date.

- Reduced-order modeling capabilities in Ansys optiSLang software lessened the computational load of full-scale simulations to predict fatigue under various conditions more easily and optimize workflows.

Komatsu developed an efficient method to predict engine failure using multiphysics simulation solutions from Ansys, part of Synopsys. Source: Adobe Stock Images. This image is for illustrative purposes only and does not depict the actual product or component.

Benefits

- Using an optimized simulation workflow, the team evaluated TMF 15X faster than traditional computer-aided engineering (CAE) methods.

- By analyzing TMF and exhaust gas heat flow using Ansys simulation, Komatsu developed a prediction method for engine component life and determined optimal timing for part replacement.

- With the help of reduced-order models (ROMs) of fluid simulations for TMF, the team produced the necessary structural data more easily than expected.

- The new prediction method enabled by Ansys solutions led to rapid design life assessment — taking less than a minute — under defined loading conditions.

Cominciamo

Se devi affrontare sfide di progettazione, il nostro team è a tua disposizione per assisterti. Con una vasta esperienza e un impegno per l'innovazione, ti invitiamo a contattarci. Collaboriamo per trasformare i tuoi ostacoli ingegneristici in opportunità di crescita e successo. Contattaci oggi stesso per iniziare la conversazione.