-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

ANSYS BLOG

February 13, 2020

Top 4 Factors to Unlock Simulation-Driven Design

Chad Jackson is the chief analyst of Lifecycle Insights.

Simulation-driven design provides a broad range of benefits that help organizations realize business goals and expedite innovation. However, while some teams using this method thrive, others are unable to fully capitalize on it.

Learn more about simulation-driven design from this infographic.

It’s easy to understand why this disparity exists. Organizations might expect that informing their design process through simulation is complex, since it requires specialist knowledge and coordination across a range of domains.

Without an appropriate level of support and tools, it can be difficult for teams to conduct analysis during design. However, a handful of new technologies can mitigate these issues. There is no better time than now for organizations to embrace simulation-driven design.

So, here are four factors that affect simulation-driven design.

To learn more about real-time simulation analysis, read the report: The Four Benefits of Simulation-Driven Design and get your hands on an Ansys Discovery free trial.

1. The Impact of CAE Familiarity on Simulation-Driven Design

Traditionally, engineers needed to understand computer-aided engineering (CAE) methods to set up an accurate analysis.

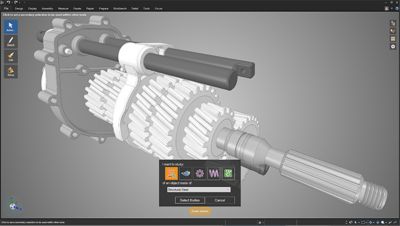

Starting a simulation in Ansys Discovery Live is as simple as picking from one of the five options: thermal, fluids, structural, model or electronics.

For example, finite element methods (FEM) will produce different results than finite difference methods (FDM). While both are numerical methods that solve physical equations, they operate on different assumptions, simplifications and methodologies.

Without this level of insight, engineers may choose the wrong method for their simulations. Additionally, if they do not understand the differences between numerical methods, they cannot properly interpret their results.

Incorrect results, or interpretations, can lead to negative repercussions. At best, engineers waste time completing a simulation that’s unfit for the stated purpose. At worst, errors creep into the simulation-driven design process causing costly failures for the organization.

Fortunately, recent developments mitigate these risks. New analysis solution algorithms can review an analysis model and automatically select the best solver, or numerical method, for the simulation. As a result, engineers can set up and run accurate analyses without understanding the fundamentals of every numerical method.

2. How CAD Training Affects Simulation-Driven Design

The primary purpose of simulation-driven design is to enable engineers to make better decisions throughout the design process.

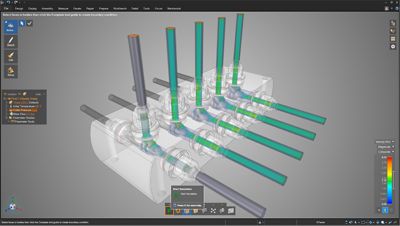

Changing geometry in Ansys Discovery Live automatically updates the simulation.

Instead of verifying and validating a product’s performance, simulation results drive changes in the computer-aided design (CAD) geometry.

Therefore, engineers need the ability to modify the geometry to iterate and explore new design paths in a virtual domain. The challenge is that the traditional approach to building and modifying geometry relies on parametric modeling — making geometries sensitive to changes.

For example, a simulation may need to maintain the same dimensions for a specific component. If an engineer unwittingly makes this change to the geometry without understanding its impact, the model will fail. Such issues can take hours to identify and resolve.

Engineers need to explore new design alternatives without breaking the model. To solve this issue, recent advancements integrate direct modeling with simulation. Using direct modeling, engineers can select, push, pull and drag geometry into a desired shape without models failing.

Consequently, direct modeling brings other benefits to the design process. For instance, it delivers speed and agility because engineers don’t need to understand the internal logic of the model.

3. How User Interfaces Affect Simulation-Driven Design

The mathematics behind simulation analysis is highly complex. Modeling a real-world system requires defining loads, constraints and other relevant properties. Engineers must know how to use all of these capabilities within a user interface (UI) to use traditional CAD software.

Setting up an internal flow simulation in Ansys Discovery Live is as simple as declaring an inlet, outlet and hitting play.

In recent times, however, solution providers have emphasized ease of use to help engineers quickly set up models. So, the latest generation of simulation applications provide intuitive UIs that facilitate analysis.

Furthermore, solution providers have layered the functionality of these applications for progressive exploration. The UI prominently presents frequently used capabilities and progressively exposes the user to more sophisticated capabilities — enabling the discovery of advanced functionalities.

For instance, auto-meshers mitigate the complexity of CAE software. They create high-quality finite element meshes to produce high-fidelity results. The application increases the density of the mesh while gradually running a sequence of analyses. The application tracks the response until a result becomes consistent and stable — a signal that the mesh is dense enough to accurately capture the phenomena.

Engineers can also gain access to UIs that take the complexities of meshing out of their hands. From the user's point of view, the software goes from geometry straight to simulation. This way, engineers can focus on finding an optimal design through direct manipulation and experimentation of the geometry without the need of a mesh.

The convergence of CAD and CAE UIs have also reduced the burden on engineers to understand the full capabilities of these software products. Thanks to UI simplifications, engineers can use simulation applications early, and more often, in the design cycle.

4. Knowledge of Engineering Physics is Key to Simulation-Driven Design

To fully capitalize on simulation-driven design, engineers can’t cut corners when it comes to their expertise. They still need in-depth knowledge of a range of engineering disciplines to understand what their results mean.

Without that knowledge, they could easily make the wrong design decision because they:

Software can't replace the knowledge of engineers.

- Do not know what their simulations represent

- Do not notice how improper inputs led to incorrect results

While many hail artificial intelligence and machine learning as means to augment worker knowledge, it seems unlikely that a robot will fully replace the expertise of a human engineer.

So, even though engineers can create simulations without selecting a numerical method, manipulate geometry risk free and use simple CAD/CAE UIs, in-depth knowledge of engineering physics cannot be replaced. However, with the right software, this knowledge gap can be solved by a new hire or engineering training.

To learn more about real-time simulation analysis, read the report: The Four Benefits of Simulation-Driven Design and get your hands on an Ansys Discovery free trial.

Any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans such as Ansys and Ansys Discovery Live are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries.

All images and videos in this blog of Ansys Discovery Live are produced by Ansys.